Product Description

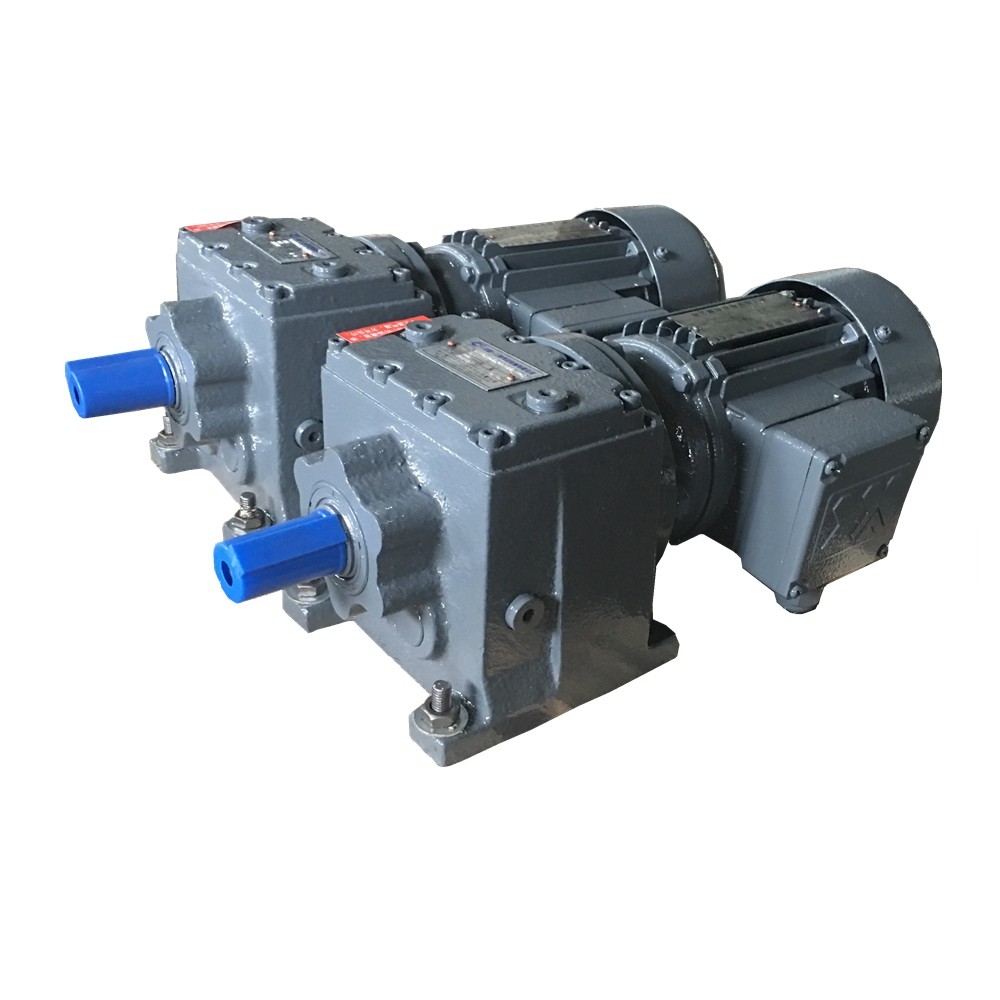

Agriculture Gear Box Farm Right Angle 540 Rpm Agricultural Lawn Mower Tractor Tiller PTO Gearbox for Rotary Cutter Feed Mixer Post Hole Digger Baler

Product Description

Ever-power Group is committed to the development, manufacturing, sales, and service of transmissions, with products covering various series such as gearboxes, agricultural machinery accessories, PTO shafts, and nearly dry specifications. Widely used in various fields such as lawn mowers, harvesters, rotary tillers, pesticide sprayers, fertilizer applicators, potato harvesters, snow plows, garden machinery, and oil extraction equipment. We provide high-quality products and professional services to multiple countries and regions around the world in the Chinese and international agricultural machinery transmission markets

Our gearbox has many items for you to choose from. We can produce according to your drawings or samples to meet your special requirements

1. Large output torque

2. Safe, reliable, economical and durable

3. Stable transmission and quiet operation

4. High bearing capacity

5. Highly modular design, which can be easily equipped with various external power inputs. The same machine type can be equipped with various power motors. It is easy to realize the combination and connection between each machine type

6. Transmission ratio: fine division and wide range. The type of modular machine tool may form a very large transmission ratio, that is, the output speed is very low.

7. Installation form: installation position is not limited.

8. High-strength and compact high-strength cast iron box, gear and gear shaft adopt gas carbonization, quenching and fine grinding process, so the bearing capacity per unit volume is high.

9. Long service life: under the condition of normal operation and maintenance by selecting the correct type (including selecting the appropriate operating parameters), the service life of the main parts of the reducer (excluding vulnerable parts) shall not be less than 20000 hours. Vulnerable parts include lubricating oil, oil seal and bearing.

10. Low noise: Since the main parts of the reducer have been strictly processed and tested, the noise of the reducer is low.

11. Our gear box has reached the international advanced level and can replace imported similar products.

Related products

The mower connects the gearbox and the plow harrow through the PTO shaft, and transmits the power to the gearbox through the PTO shaft, thus driving the mowing blade to operate. We can also produce various types of PTO shafts. Please consult us

Click the picture to learn more about the pto shafts

Company Profile

HangZhou CHINAMFG Transmission Co., Ltd. is a professional supplier of various chains, sprockets, gears, racks, V-belts, timing pulleys, V-belts, couplings, machining parts, etc.

Because we sincerely provide customers with the best service, understand your needs, and have an overwhelming sense of responsibility to meet the order requirements, we have won the trust of global buyers. We have accumulated valuable experience in cooperation with foreign customers, and our products sell well in the United States, Europe, South America and Asia. Our products are manufactured by modern computerized machines and equipment. At the same time, our products are manufactured according to high quality standards and conform to international advanced standards.

With years of experience in this field, we will be trusted for its competitive price, one-time delivery, rapid response, existing engineering support and good after-sales service.

In addition, all our production procedures comply with the ISO9001 standard. We can also design and manufacture non-standard products to meet the special requirements of customers. Quality and reputation are the foundation of enterprise survival. We will wholeheartedly provide you with the best service and high-quality products. If you need any information or samples, please contact us and we will reply to you as soon as possible.

Production and inspection

Our gearbox will undergo strict test before shipment, including oil leakage test and reverse test

Packing

Finished goods inventory

Certificate

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Three-Step |

| Samples: |

US$ 165/Piece

1 Piece(Min.Order) | |

|---|

Considerations for Heavy-Duty Farming Gearboxes

Heavy-duty farming applications require robust and reliable gearboxes that can withstand high loads, harsh conditions, and frequent use. Here are the key considerations for selecting gearboxes for heavy-duty farming:

- Load Capacity: Heavy-duty gearboxes must have a high load-carrying capacity to handle the demands of agricultural machinery, such as tillers, plows, and combines.

- Material Durability: Gearboxes should be constructed from durable materials, such as hardened steel or cast iron, that can withstand the stresses and impacts associated with heavy-duty tasks.

- Sealing and Protection: Effective sealing and protection mechanisms, such as robust seals and gaskets, prevent the ingress of dirt, water, and contaminants that can cause premature wear and damage.

- Lubrication System: A reliable and efficient lubrication system is crucial for heavy-duty gearboxes to ensure proper lubrication of components under high loads and temperatures.

- Heat Dissipation: Heavy-duty applications generate significant heat. Gearboxes should have efficient heat dissipation mechanisms, such as cooling fins or oil coolers, to prevent overheating and maintain performance.

- Design and Construction: Gearbox design should incorporate reinforced housing, larger bearings, and robust gears to handle heavy loads without compromising structural integrity.

- Alignment and Mounting: Proper alignment and mounting are essential to ensure smooth and efficient power transmission. Misalignment can lead to increased wear and reduced gearbox lifespan.

- Maintenance Accessibility: Heavy-duty gearboxes should be designed for easy maintenance access. Features such as removable covers and inspection points simplify servicing and repairs.

- Compatibility: Gearboxes should be compatible with the specific machinery and tasks they will be used for. Customizable gear ratios and output shaft configurations enhance versatility.

- Reliability and Longevity: Heavy-duty gearboxes should be built to last, with quality craftsmanship and components that can withstand the demanding conditions of agricultural operations.

- Safety: Safety features, such as guards and emergency shutdown mechanisms, are essential to protect operators and nearby personnel from potential hazards.

- Environmental Considerations: Gearbox designs should consider environmental regulations and emissions standards to minimize the impact on the environment.

- Cost-Effectiveness: While heavy-duty gearboxes require a higher upfront investment, their durability and performance contribute to long-term cost-effectiveness by reducing downtime and the need for frequent replacements.

By carefully considering these factors, farmers can select the appropriate heavy-duty gearboxes that enhance productivity and reliability in their farming operations.

Factors to Consider When Selecting the Right Gearbox for Farm Machinery

Choosing the appropriate gearbox for farm machinery is crucial to ensure optimal performance and efficiency. Here are the key factors to consider when selecting the right gearbox:

- Power and Torque Requirements: Assess the power and torque needed for the specific task the machinery will perform. Select a gearbox that can handle the required load without straining the components.

- Speed Variation: Determine if the machinery requires variable speed control for different tasks. Some gearboxes offer adjustable speed options to match varying conditions and applications.

- Task Compatibility: Ensure that the chosen gearbox is compatible with the implements and attachments the machinery will use. Different tasks may require different gear ratios and torque capabilities.

- Efficiency: Opt for gearboxes known for their efficiency in power transmission. Efficient gearboxes minimize energy losses and maximize the output of the machinery.

- Durability: Farming environments can be demanding, so select a gearbox that is built to withstand the conditions, such as exposure to dirt, moisture, and impacts.

- Size and Weight: Consider the available space and weight limits on the machinery. Choose a gearbox that fits within these constraints without compromising performance.

- Maintenance: Evaluate the maintenance requirements of the gearbox. Gearboxes that are easy to maintain and service can minimize downtime and keep the machinery running smoothly.

- Cost: Balance the initial cost of the gearbox with its long-term benefits and performance. Investing in a quality gearbox can lead to better overall cost-effectiveness over time.

- Compatibility: Ensure that the gearbox is compatible with the power source (such as the tractor’s power take-off) and other components of the machinery.

- Manufacturer Reputation: Choose gearboxes from reputable manufacturers with a history of producing reliable and high-quality agricultural machinery components.

By carefully considering these factors, farmers can select the right gearbox that meets the specific needs of their farm machinery, leading to enhanced efficiency, productivity, and longevity of equipment.

Key Features of a Durable and Reliable Agricultural Gearbox

A durable and reliable agricultural gearbox is crucial for the efficient operation of farming equipment and machinery. The following key features contribute to the durability and reliability of agricultural gearboxes:

- High-Quality Materials: Agricultural gearboxes are often exposed to harsh conditions, including dust, debris, and varying weather. Using high-quality materials, such as strong alloy steels, can enhance the gearbox’s resistance to wear, corrosion, and other forms of deterioration.

- Rugged Construction: The gearbox should have a robust and rugged construction to withstand the stresses and strains associated with agricultural tasks. Reinforced housings, precision machining, and robust seals can help prevent damage and ensure longevity.

- Effective Lubrication System: Proper lubrication is vital to reduce friction, dissipate heat, and prevent premature wear. Agricultural gearboxes should be equipped with efficient lubrication systems that ensure all components are adequately lubricated, even during extended operation.

- Sealing and Protection: Dust, dirt, and moisture are common challenges in agricultural environments. Effective sealing mechanisms, such as gaskets and seals, prevent contaminants from entering the gearbox and protect internal components from damage.

- Heat Dissipation: The gearbox should be designed to dissipate heat effectively, especially during prolonged operation. Overheating can lead to lubrication breakdown and premature wear. Cooling fins and adequate ventilation can help maintain optimal operating temperatures.

- Gear Quality and Precision: High-quality gears with accurate tooth profiles and precision manufacturing ensure smooth and efficient power transmission. Properly machined gears reduce noise, vibration, and the risk of gear failures.

- Advanced Gear Design: Some agricultural gearboxes may feature advanced gear designs, such as helical or planetary gears. These designs offer improved efficiency, reduced noise, and increased load-bearing capacity compared to traditional spur gears.

- Overload Protection: Incorporating overload protection mechanisms, such as shear pins or clutch systems, can prevent damage to the gearbox and other connected components in case of sudden high loads or jams.

- Easy Maintenance Access: The gearbox should be designed with maintenance in mind. Accessible inspection points, drain plugs, and fill ports make it easier for operators to perform routine maintenance tasks.

Manufacturers often engineer agricultural gearboxes to meet these requirements, ensuring that they can withstand the demanding conditions of farming operations and contribute to the reliable performance of agricultural machinery.

editor by CX 2024-03-29

China Right Angle Gear Box Pto Farm Rotary Slasher Feeder Mixer Rotary Tiller Cultivator Baller Tractor Agricultural Machinery Parts Bevel Gearbox agricultural gearboxes

Item Description

Solution Description

Organization Profile

In 2571, HangZhou CZPT Machinery Co.,ltd was set up by Ms. Iris and her 2 associates(Mr. Tian and Mr. Yang) in HangZhou town(ZHangZhoug province, China), all 3 Founders are engineers who have more than averaged 30 a long time of expertise. Then because the requirements of business expansion, in 2014, it moved to the present Xihu (West Lake) Dis. Industrial Zone (HangZhou town, ZHangZhoug province, China).

Through our effectively-known brand ND, CZPT Machinery provides agricultural answers to agriculture machinery producer and distributors around the world by means of a entire line of spiral bevel gearboxes, straight bevel gearboxes, spur gearboxes, drive shafts, sheet steel, hydraulic cylinder, motors, tyre, worm gearboxes, worm operators etc. Goods can be customized as request.

We, CZPT equipment set up a total top quality management technique and sales services community to offer customers with substantial-top quality items and satisfactory support. Our goods are marketed in forty provinces and municipalities in China and 36 countries and regions in the planet, our principal industry is the European market place.

Certifications

Our Manufacturing facility

Sample Area

Why select us?

one) Customization: With a sturdy R&D crew, and we can develop merchandise as essential. It only requires up to 7 days for us to design and style a established of drawings. The manufacturing time for new merchandise is typically 50 times or much less.

two) Good quality: We have our personal total inspection and testing tools, which can ensure the high quality of the goods.

3) Potential: Our annual creation ability is in excess of five hundred,000 sets, also, we also take little quantity orders, to satisfy the requirements of diverse customer’s obtain quantities.

four) Services: We concentrate on offering high-top quality products. Our merchandise are in line with worldwide requirements and are mostly exported to Europe, Australia, and other countries and areas.

5) Shipment: We are shut to HangZhou and ZheJiang ports, to offer the swiftest delivery support.

Packaging & Transport

FAQ

Q: Are you a investing business or producer?

A: We’re manufacturing facility and providing gearbox ODM & OEM providers for the European market place for far more than ten years

Q: Do you provide samples? is it free or further?

A: Sure, we could supply the sample for cost-free demand but do not shell out the cost of freight.

Q: How lengthy is your shipping and delivery time? What is your phrases of payment?

A: Generally it is 40-45 times. The time could differ depending on the product and the level of customization.

For regular items, the payment is: 30% T/T in advance,balance just before cargo.

Q: What is the exact MOQ or price tag for your item?

A: As an OEM firm, we can offer and adapt our goods to a broad range of needs.

Thus, MOQ and price tag might tremendously range with dimensions, content and even more technical specs For instance, expensive goods or common merchandise will typically have a reduce MOQ. Make sure you get in touch with us with all related particulars to get the most precise quotation.

If you have an additional question, you should come to feel free of charge to get in touch with us.

|

US $10-300 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Straight or Spiral Bevel Gear |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

###

| Customization: |

Available

|

|---|

|

US $10-300 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Straight or Spiral Bevel Gear |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

###

| Customization: |

Available

|

|---|

Choosing the Right Agricultural Gearbox

When buying an agricultural gearbox, there are a few things to consider. The quality of materials, functionality, and mechanism are crucial factors to durability. A durable device will ensure that you won’t have to keep replacing it. Here are some tips to help you select the right one. Let’s begin. Read on to learn more about the different features available in agricultural gearboxes. Listed below are a few of the most important factors to consider.

Bevel gearboxes

Agricultural gearboxes are essential to the entire food cycle. If your gears are not in good shape, you will be unable to meet the demand and you will suffer from heightened downtime. Fortunately, there are numerous quality bevel gearboxes available on the market today. In fact, the CZPT Gearbox Company supplies bevel gearboxes for agricultural applications. Here are some of the reasons you should choose the right one.

A bevel gearbox is a single-stage unit that interlocks bevelled edges on two gears to transfer torque and rotation. These gears can be either straight or helical. This type of gearbox is inexpensive to produce and operates quietly. It also has lower transmittable torque. Bevel gearboxes are often used as a low-cost alternative to hypoid gearboxes.

Agricultural bevel gearboxes are used in various applications, including hay balers, combine harvesters, seeders, and plows. These gears are well-suited for use with offset rotary fillers. They offer reduction ratios of up to 2.44 and cast iron cases. They are commonly known as “right-angle gearboxes” or “Parallel SHAFT gearboxes.”

Agricultural bevel gearboxes come in many sizes and ratios. In general, higher sizes are made of closed-grain cast-iron. Other materials, such as SG 500/7, are used for larger sizes. The main gear and each drive gear are mesh-mounted, and the shafts are designed to rotate in either direction. They have oil seals on the joints. The Spiral Bevel Gearbox is best suited for FG60 or FG75 motors.

The RINV-OP65 right-angle angular gearbox comes with an optional electronic or mechanical position indicator. Its angular design allows for changes in axis rotation, and provides smooth power transmission with minimal backlash. Premium gearmotors include hardened spiral bevel gears and stainless steel shafts for quiet operation. They are available in various ratios and shaft styles. If you want to choose one, make sure it is made to fit the needs of the machine.

Closed-loop seals

There are a number of reasons to install closed-loop seals in an agricultural gearbox. The first is the need to isolate the gearbox from the atmosphere, an important safety concern. Closed-loop seals are CZPT alternatives to desiccant breathers because they prevent the entry of water. While these seals can’t keep the gearbox underwater, they isolate the gearbox from the atmosphere and are therefore vital for the safety of your equipment.

The most common material used for these seals is polymer rubber. Most are made from HBR, which stands for High-cis polybutadiene rubber. Other materials include Butadiene and FKM, which are known for their high-temperature performance. However, the disadvantage of these seals is that they are susceptible to shaft damage and degrade quickly in high temperatures. Therefore, you should always consider the type of seal before purchasing one.

If you plan to use agricultural gearboxes on a regular basis, you should consider getting a good quality one. You should look for a closed-loop seal on your gearbox to protect it against dirt and debris. A quality agricultural gearbox also has an easy-access design, which will make it easy to access and maintain. This will ensure its long-lasting performance and low-maintenance costs.

Agricultural equipment is frequently used to perform various tasks, such as sowing seeds, spreading fertilizer, digging holes, and more. This requires durable and effective sealing solutions to keep dirt out of the system and lubricants in. A close-loop seal helps to ensure that all these operations are performed at maximum efficiency. If you’re a farmer, closed-loop seals are the ideal solution for you.

Surface finish

The surface finish of an agricultural gearbox should be free from defects in the casting process and mechanical damage. The bearing hole in the shaft must be a minimum of 100 mm long and the distance between the bearing holes should be equal to the shaft length. The shaft should be free of any cracks or burrs. The ellipticity and centerline irregularity of the shaft must be less than 0.015 mm. Likewise, the diameter of the shaft, hole spacing and bearing hole relationship should be at least 20 mm.

In recent studies, researchers have investigated the efficiency of different surfaces on the same materials. They found that surface roughness affects gearbox efficiency. Kahraman et al. reported that superfinishing the gears and reducing surface roughness improved efficiency. In addition, Andersson et al. investigated the impact of different assembly processes on the gearbox’ surface roughness. The results of their studies are presented in Table I.

The quality of the surface finish of an agricultural gearbox depends on the materials used. A typical example is wrought steel gear. The die inserts for a forged gear were made of H11 or H13 tool steel. This material softens over time and has a limited life span. An improved alternative was Alloy 718. This alloy has a high temperature range and is suitable for high rotational speeds.

A good surface finish is vital for the health and safety of an agricultural gearbox. It protects the entire food chain and is necessary for agricultural production. The heightened demand for food will cause increased wear and tear on farm machinery. Moreover, a damaged gear will cost the farmer a lot of money. Therefore, it is crucial for farmers to invest in a high-quality agricultural gearbox to avoid such costly downtimes.

Shaft arrangement

An agricultural gearbox has two main stages, the first of which is the reduction stage. The reduction stage contains the pinion, a series of gears, and the first reduction stage. A second stage is connected to the first reduction stage via a mechanical clutch. This gearbox typically consists of three stages. The first reduction stage is also known as the low gear “L”. The first reduction stage provides four forward gearing ratios, while the second stage has three forward gearing ratios. A conventional agricultural gearbox also incorporates a mechanical clutch.

The second stage is a speed change gearbox. It has an input and output shaft. The input shaft is rotatably mounted in the casing and extends through the tractor’s interior. The shaft extends to the rear of the tractor, where the driven part of the joint 26 is keyed onto. The rear end portion of the shaft projects into the back axle casing 15, where it is connected to the first transmission shaft 34. The gearbox then serves to drive the power take-off shaft 36.

Newer types of tractors have larger shafts to support higher power applications. Type 3 tractors have a larger shaft with 20 splines while Type 2 tractors have a smaller shaft. The Type 2 is often referred to as the small 1000. When viewed from inside the tractor cab, Type 3 and Type 2 are rotated counterclockwise. If you are unfamiliar with agricultural gearboxes, here are some basic terms.

Shaft arrangement is important in choosing the right gearing system for agricultural machinery. There are a few differences between these arrangements. The first type has a higher gear ratio, while the second has lower. In terms of speed, the shaft arrangement of an agricultural gearbox reflects the speed of the machinery. The higher the speed of the gear, the higher the output speed. So, when choosing a gearbox, keep this in mind.

Cost

Purchasing an agricultural gearbox may be a costly process, but the benefits outweigh the price. Agricultural gearboxes are vital to the food cycle. When a gear breaks down, farmers will face significant losses. Additionally, agricultural applications use a high-quality gearbox to minimize equipment wear and tear. Ultimately, a high-quality gearbox will reduce the cost of production while extending the lifespan of the agricultural machinery.

Many countries trade in Agriculture Gearbox with India, and many of these suppliers are located in India. Using a marketplace to buy from Indian suppliers offers several advantages. Among the many factors to consider when choosing an Agriculture Gearbox supplier are quality, price, reliability, and past trade history. Through a marketplace like CZPT, you can obtain 360-degree information on Indian Agriculture Gearbox suppliers. In this way, you can choose a vendor with whom you do business.

CZPT Gearbox Company is a leading manufacturer of high-quality agricultural gearboxes. Their experienced engineers can reverse-engineer an existing design for a custom-made gearbox for your needs. Whether you need a smaller or larger gearbox for an agricultural application, CZPT Gearbox Company is your partner. A line of high-quality agricultural gearboxes from CZPT Gearbox Company will help you maximize the performance of your farm machinery. They will transfer rotational power from the input shaft to the output shafts, allowing for a change in speed, direction, and rotation.

editor by czh 2023-01-29

China Custom Feed Mixer Planetary Gearbox Agricultural PTO gear box agricultural machinery gearboxes

Applicable Industries: Manufacturing Plant, Machinery Repair Shops, Farms

Gearing Arrangement: Planetary

Output Torque: 12571Nm;18571Nm;13500Nm;16000Nm

Input Speed: 540rpm/1000rpm

Output Speed: Ratio21.1:1, 13.4:1, 18.2:1

Model Number: XHG01series

Rated Power: 32.18HP;76.04HP;72.62HP

paint color: red prime coat

Weight: 256Kg;290Kg;280Kg

Packaging Details: wooden case suitable for exportation;

Port: ZheJiang

Feed Mixer Planetary Gearbox

XHG01 series is a new type jiont developed by our company and domestic university. With its characteristics of big torque, reliable function, stable transmission, low noise, easy to be lubricated and long service life, it is widely used for industrial and agricultural agitators.

This series gearbox has already achieved national patent.

Details:

– ISO9001 Quality System examined & verified by Third Party of CQC and passed second-degree safety quality standardization for machinery manufacturing enterprise.

– Precision forging, cutting by CNC machine, heat treatment by German IPSON & laser techniques .

– Strictly quality control by German CMM.

– Various of gearboxes used in agricultural machines and industrial machines.

– Advanced technics, strong self-development power, CZPT to produce new type gearbox according to customer’s design drwings.

| Code | Gear Ratio(i) |

Power (HP) |

Output Torque (Nm) |

Input Speed (r.p.m.) |

Input Torque (Nm) |

Weight (kg) |

| XHG01.51000.00 | 21.108 | 32.18 | 12571 | 540 | 569 | 256 |

| XHG01.51000.01 | 13.402 | 76.04 | 18571 | 540 | 1345 | 256 |

| XHG01.51000.02 | 25.986 | 72.62 | 18571 | 1000 | 693 | 290 |

| XHG01.51000.03 | 18.218 | 41.90 | 13500 | 540 | 741 | 256 |

| XHG01.51000.04 | 13.402 | 67.51 | 16000 | 540 | 1194 | 256 |

| XHG01.51000.05 | 13.402 | 76.04 | 18571 | 540 | 1345 | 280 |

| XHG01.51000.06 | 25.986 | 76.62 | 18571 | 1000 | 693 | 290 |

| XHG01.51000.07 | 25.986 | 76.62 | 18571 | 1000 | 693 | 290 |

| XHG01.51000.08 | 28.321 | 59.16 | 16000 | 1000 | 565 | 290 |

| XHG01.51000.09 | 28.321 | 59.16 | 16000 | 1000 | 565 | 290 |

Design Patent:

How to Select a Gearbox

When you drive your vehicle, the gearbox provides you with traction and speed. The lower gear provides the most traction, while the higher gear has the most speed. Selecting the right gear for your driving conditions will help you maximize both. The right gearing will vary based on road conditions, load, and speed. Short gearing will accelerate you more quickly, while tall gearing will increase top speed. However, you should understand how to use the gearbox before driving.

Function

The function of the gearbox is to transmit rotational energy to the machine’s drive train. The ratio between input and output torque is the ratio of the torque to the speed of rotation. Gearboxes have many different functions. A gearbox may have multiple functions or one function that is used to drive several other machines. If one gear is not turning, the other will be able to turn the gearbox. This is where the gearbox gets its name.

The pitch-controlled system has an equal number of failure modes as the electrical system, accounting for a large proportion of the longest machine downtime and halt time. The relationship between mechanisms and faults is not easily modeled mathematically. Failure modes of gearboxes are shown in Fig. 3. A gearbox’s true service life is six to eight years. However, a gearbox’s fault detection process must be developed as mature technology is required to reduce the downtime and avoid catastrophic incidents.

A gearbox is a vital piece of machinery. It processes energy produced by an engine to move the machine’s parts. A gearbox’s efficiency depends on how efficiently it transfers energy. The higher the ratio, the more torque is transferred to the wheels. It is a common component of bicycles, cars, and a variety of other devices. Its four major functions include:

In addition to ensuring gearbox reliability, a gearbox’s maintainability should be evaluated in the design phase. Maintainability considerations should be integrated into the gearbox design, such as the type of spare parts available. An appropriate maintenance regime will also determine how often to replace or repair specific parts. A proper maintenance procedure will also ensure that the gearbox is accessible. Whether it is easy to access or difficult to reach, accessibility is essential.

Purpose

A car’s transmission connects the engine to the wheels, allowing a higher-speed crankshaft to provide leverage. High-torque engines are necessary for the vehicle’s starting, acceleration, and meeting road resistance. The gearbox reduces the engine’s speed and provides torque variations at the wheels. The transmission also provides reversing power, making it possible to move the vehicle backwards and forwards.

Gears transmit power from one shaft to another. The size of the gears and number of teeth determine the amount of torque the unit can transmit. A higher gear ratio means more torque, but slower speed. The gearbox’s lever moves the engaging part on the shaft. The lever also slides the gears and synchronizers into place. If the lever slips to the left or right, the engine operates in second gear.

Gearboxes need to be closely monitored to reduce the likelihood of premature failure. Various tests are available to detect defective gear teeth and increase machine reliability. Figure 1.11(a) and (b) show a gearbox with 18 teeth and a 1.5:1 transmission ratio. The input shaft is connected to a sheave and drives a “V” belt. This transmission ratio allows the gearbox to reduce the speed of the motor, while increasing torque and reducing output speed.

When it comes to speed reduction, gear box is the most common method for reducing motor torque. The torque output is directly proportional to the volume of the motor. A small gearbox, for example, can produce as much torque as a large motor with the same output speed. The same holds true for the reverse. There are hybrid drives and in-line gearboxes. Regardless of the type, knowing about the functions of a gearbox will make it easier to choose the right one for your specific application.

Application

When selecting a gearbox, the service factor must be considered. Service factor is the difference between the actual capacity of the gearbox and the value required by the application. Additional requirements for the gearbox may result in premature seal wear or overheating. The service factor should be as low as possible, as it could be the difference between the lifetime of the gearbox and its failure. In some cases, a gearbox’s service factor can be as high as 1.4, which is sufficient for most industrial applications.

China dominates the renewable energy industry, with the largest installed capacity of 1000 gigawatts and more than 2000 terawatt hours of electricity generated each year. The growth in these sectors is expected to increase the demand for gearboxes. For example, in China, wind and hydropower energy production are the major components of wind and solar power plants. The increased installation capacity indicates increased use of gearboxes for these industries. A gearbox that is not suitable for its application will not be functional, which may be detrimental to the production of products in the country.

A gearbox can be mounted in one of four different positions. The first three positions are concentric, parallel, or right angle, and the fourth position is shaft mount. A shaft mount gearbox is typically used in applications where the motor can’t be mounted via a foot. These positions are discussed in more detail below. Choosing the correct gearbox is essential in your business, but remember that a well-designed gearbox will help your bottom line.

The service factor of a gearbox is dependent on the type of load. A high shock load, for example, can cause premature failure of the gear teeth or shaft bearings. In such cases, a higher service factor is required. In other cases, a gearbox that is designed for high shock loads can withstand such loads without deteriorating its performance. Moreover, it will also reduce the cost of maintaining the gearbox over time.

Material

When choosing the material for your gearbox, you must balance the strength, durability, and cost of the design. This article will discuss the different types of materials and their respective applications and power transmission calculations. A variety of alloys are available, each of which offers its own advantages, including improved hardness and wear resistance. The following are some of the common alloys used in gears. The advantage of alloys is their competitive pricing. A gear made from one of these materials is usually stronger than its counterparts.

The carbon content of SPCC prevents the material from hardening like SS. However, thin sheets made from SPCC are often used for gears with lower strength. Because of the low carbon content, SPCC’s surface doesn’t harden as quickly as SS gears do, so soft nitriding is needed to provide hardness. However, if you want a gear that won’t rust, then you should consider SS or FCD.

In addition to cars, gearboxes are also used in the aerospace industry. They are used in space travel and are used in airplane engines. In agriculture, they are used in irrigation, pest and insect control machinery, and plowing machines. They are also used in construction equipment like cranes, bulldozers, and tractors. Gearboxes are also used in the food processing industry, including conveyor systems, kilns, and packaging machinery.

The teeth of the gears in your gearbox are important when it comes to performance. A properly meshing gear will allow the gears to achieve peak performance and withstand torque. Gear teeth are like tiny levers, and effective meshing reduces stress and slippage. A stationary parametric analysis will help you determine the quality of meshing throughout the gearing cycle. This method is often the most accurate way to determine whether your gears are meshing well.

Manufacturing

The global gear market is divided into five key regions, namely, North America, Europe, Asia Pacific, and Latin America. Among these regions, Asia Pacific is expected to generate the largest GDP, owing to rapidly growing energy demand and investments in industrial infrastructure. This region is also home to some of the largest manufacturing bases, and its continuous building of new buildings and homes will support the industry’s growth. In terms of application, gearboxes are used in construction, agricultural machinery, and transportation.

The Industrial Gearbox market is anticipated to expand during the next several years, driven by the rapid growth of the construction industry and business advancements. However, there are several challenges that hamper the growth of the industry. These include the high cost of operations and maintenance of gear units. This report covers the market size of industrial gearboxes globally, as well as their manufacturing technologies. It also includes manufacturer data for the period of 2020-2024. The report also features a discussion of market drivers and restraints.

Global health crisis and decreasing seaborne commerce have moderately adverse effects on the industry. Falling seaborne commerce has created a barrier to investment. The value of international crude oil is expected to cross USD 0 by April 2020, putting an end to new assets development and exploitation. In such a scenario, the global gearbox market will face many challenges. However, the opportunities are huge. So, the market for industrial gearboxes is expected to grow by more than 6% by 2020, thanks to the increasing number of light vehicles sold in the country.

The main shaft of a gearbox, also known as the output shaft, spins at different speeds and transfers torque to an automobile. The output shaft is splined so that a coupler and gear can be connected to it. The counter shaft and primary shaft are supported by bearings, which reduce friction in the spinning element. Another important part of a gearbox is the gears, which vary in tooth count. The number of teeth determines how much torque a gear can transfer. In addition, the gears can glide in any position.

in Be’er Sheva Israel sales price shop near me near me shop factory supplier Stainless Steel Ring and Pinion Large Revolution Synchronizer Axle Flywheel Internal Fin Magnetic Cement Mixer Ring Gear Manufacturer Industrial manufacturer best Cost Custom Cheap wholesaler

If you need any information or samples, you should get in touch with us and you will have our quickly reply. We can provide a complete-range of electrical power transmission goods like chains, sprockets and plate wheels, pulleys, gearboxes, motors, couplings, gears and racks. We also can style and make non-common items to fulfill customers’ unique specifications.

stainless steel ring and pinion huge revolution synchronizer axle flywheel inner fin magnetic cement mixer Ring EPT company EPTT

Wpwd factory Outlet Speed Reducer Gearbox Wpwd speed reducer gear drive gearbox for concrete mixer sell gearbox 3 speed transmission

Every single process, each part, each operate in EPG is demanded to be completed one particular action adhering to another, very carefully and cautiously, from substance choice, reformation to production add-ons, from factors heat treatment to computerized assembly, from top quality control to item inspection and testing and from buy dealing to following sales support. EPG has been effectively licensed by ISO9002 High quality Administration Method, ISO9001 Quality Management Method, API certification, ISO/TS16949:2002 and ISO10012 measurement management technique. The item properly shows environmental security and strength saving.

Overview

Quick Details

- Gearing Arrangement:

-

Helical

- Output Torque:

-

one.eight-2430N.M

- Input Velocity:

-

1400rpm

- Output Velocity:

-

19-186.7rpm

- Location of Origin:Zhejiang, China

- Model Identify:

-

OEM

- Coloration:

-

silver, blue, black and so on

- velocity ratio:

-

1/5-1/6

- size:

-

forty,50,sixty,70,eighty,100,a hundred and twenty,a hundred thirty five,147,155,a hundred seventy five,200,250

Offer Ability

- Provide Ability:

- 1200 Device/Models for each Month

Packaging Supply

- Packaging Particulars

- Picket bins , Cantons packed in 1 pallet

- Port

- Zhejiang/Ningbo Port

- Photo Example:

-

Guide Time

: -

Amount(Models) one – 1 >1 Est. Time(times) 25 To be negotiated

On-line Customization

Solution Description

Wpwd Pace Reducer Gearbox Wpwd speed reducer nbsp gear travel gearbox for concrete mixer market gearbox three speed transmission nbspanufacture

Principal Attributes

1.Housing:iron solid

2. minimal sound( lt50DB) nbsp

three.Model:WPDA 40-250,Ratio:10 to 60 nbsp

four.Productive and secure working nbsp

nbsp

Firm Info

nbsp

Top quality control

nbsp

nbsp

Our Certifications

nbsp

nbsp

Connected Solution

nbsp

nbsp

FAQ

nbsp

one.Payment Phrase: TT, L/C

nbsp

two.Shipping and delivery time: about nbsp 30 times from get payment. nbsp

nbsp

three.We acknowledge tailored products as for every your unique prerequisite.

nbsp

4.Tips for the Variety:Normally we can decide on a single equipment which is appropriate for you with some informations from you,this sort of as ratio/motor speed/mounting dimension/ out torque etc. nbsp

nbsp

five.If the bare minimum buy amount is in extra of $ten thousand, there are preferential.

nbsp

Q1: What info should I inform you to confirm the merchandise?

A:Model/Dimension, Transmission Ratio, Shaft instructions amp Get amount.

nbsp

Q2: What can i do if I will not know which 1 I need?

A:Dont be concerned, Ship as much info as you can, our team will support you find the proper 1 you are looking for.

nbsp

Q3: What is your item warranty period of time?

A:We offer a single yr guarantee since the vessel departure day left China.

nbsp

This autumn: Are you trading business or maker ?

A: We are factory.

nbsp

Q5: How extended is your delivery time?

A: Typically it is 5-10 days if the merchandise are in inventory. or it is 15-20 times if the products are not in stock, it is in accordance to quantity.

nbsp

Q6: Do you offer samples ? is it cost-free or added ?

A: Yes, we could offer you the sample for free of charge cost but do not pay the value of freight.

nbsp

Q7: What is your terms of payment ?

A: Payment lt=1000USD, 100% in progress. Payment gt=1000USD, 30% T/T in progress ,equilibrium ahead of shippment.

nbsp

If you have yet another issue, pls come to feel cost-free to contact us as under:

Make contact with Us

nbsp

Wp factory Outlet Speed Reducer Gearbox For Concrete Mixer Worm Gear Reducer The Gear Box Transmission Parts 24v Brushless Dc Motor Manufacture

We can provide a entire-variety of electrical power transmission products like chains, sprockets and plate wheels, pulleys, gearboxes, motors, couplings, gears and racks. It has recognized stable cooperation with a lot of well known universities and institutes in china such as, Zhejiang University, Jilin College, Complex committee of countrywide chain travel common, Institute of nationwide chain push, Zhejiang software engineering content institute, Huhan material defense institute and it cooperated to located China 1st Auto chain institute with Nationwide chain generate institute. Ever-Energy Group CO., LTD. IS Specialist IN Creating ALL Types OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Equipment Velocity REDUCERS, PARALLEL SHAFT HELICAL Gear REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Equipment REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Auto GEARBOXES, PTO Generate SHAFTS, Unique REDUCER & Relevant Gear Elements AND OTHER Connected Items, SPROCKETS, HYDRAULIC Method, VACCUM PUMPS, FLUID COUPLING, Gear RACKS, CHAINS, TIMING PULLEYS, UDL Velocity VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Gear PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Minimal BACKLASH WORM REDUCERS AND SO ON.

Overview

Quick Details

- Gearing Arrangement:

-

Helical

- Output Torque:

-

1.eight-2430N.M

- Enter Velocity:

-

1400rpm

- Output Velocity:

-

19-186.7rpm

- Area of Origin:Zhejiang, China

- Model Name:

-

OEM

- Color:

-

silver, blue, black and so on

- pace ratio:

-

1/five-1/6

- measurement:

-

forty,50,60,70,80,a hundred,120,a hundred thirty five,147,one hundred fifty five,a hundred seventy five,200,250

Supply Capability

- Provide Capability:

- 1200 Device/Units for every Month

Packaging Shipping

- Packaging Details

- Wood bins , Cantons packed in one pallet

- Port

- Zhejiang/Ningbo Port

- Picture Example:

-

Direct Time

: -

Amount(Units) 1 – one >1 Est. Time(days) 25 To be negotiated

On-line Customization

Item Description

Wp Speed Reducer Gearbox For Concrete Mixer Worm Equipment Reducer The Equipment Box Transmission Areas 24v Brushless Dc Motor Manufacture

Major Features

one.Housing:iron solid

2. reduced sounds( lt50DB) nbsp

3.Product:WPDA 40-250,Ratio:ten to sixty nbsp

four.Successful and risk-free functioning nbsp

nbsp

Business Information

nbsp

High quality management

nbsp

nbsp

Our Certifications

nbsp

nbsp

Associated Merchandise

nbsp

nbsp

FAQ

nbsp

one.Payment Time period: TT, L/C

nbsp

two.Delivery time: about nbsp thirty days from get payment. nbsp

nbsp

three.We acknowledge personalized merchandise as for every your specific need.

nbsp

4.Suggestions for the Selection:Normally we can decide on 1 device which is ideal for you with some informations from you,this sort of as ratio/motor velocity/mounting dimension/ out torque and many others. nbsp

nbsp

5.If the least purchase volume is in excessive of $10000, there are preferential.

nbsp

Q1: What information ought to I tell you to verify the product?

A:Design/Size, Transmission Ratio, Shaft instructions amp Purchase quantity.

nbsp

Q2: What can i do if I never know which a single I want?

A:Dont worry, Send as a lot information as you can, our group will aid you locate the right one you are hunting for.

nbsp

Q3: What is your item warranty interval?

A:We provide one yr warranty given that the vessel departure day left China.

nbsp

This fall: Are you buying and selling firm or maker ?

A: We are factory.

nbsp

Q5: How lengthy is your shipping time?

A: Normally it is 5-ten days if the goods are in inventory. or it is 15-20 days if the items are not in stock, it is in accordance to quantity.

nbsp

Q6: Do you offer samples ? is it totally free or further ?

A: Of course, we could supply the sample for free of charge charge but do not spend the price of freight.

nbsp

Q7: What is your terms of payment ?

A: Payment lt=1000USD, a hundred% in progress. Payment gt=1000USD, 30% T/T in progress ,equilibrium prior to shippment.

nbsp

If you have an additional issue, pls feel free of charge to make contact with us as under:

Speak to Us

nbsp

Gearbox Strength factory B Helical Bevel Electricity Power Reducer bevel gearbox for concrete mixer auto gearbox for tricycle diesel engine gear

The group has taken component in the creating and revising of ISO/TC100 global chain standard numerous a long time in success and hosted the sixteenth ISO/TC100 Intercontinental once-a-year conference in 2004. We can supply a full-selection of power transmission items like chains, sprockets and plate wheels, pulleys, gearboxes, motors, couplings, gears and racks. In 2008, it was awarded with “Nationwide Export Commodity Inspection-totally free Company”.

Overview

Fast Specifics

- Applicable Industries:

-

Accommodations, Garment Stores, Building Materials Shops, Production Plant, Equipment Fix Retailers, Foodstuff amp Beverage Factory, Farms, Restaurant, Home Use, Retail, Foodstuff Shop, Printing Stores, Design operates nbsp, Energy amp Mining, Food amp Beverage Stores, Marketing Organization

- Gearing Arrangement:

-

Helical

- Output Torque:

-

470000Nm

- Input Speed:

-

750-1500rpm

- Output Velocity:

-

one.seven~1200rpm

- Place of Origin:Zhejiang, China

- Manufacturer Identify:

-

OEM

- Certification:

-

ISO9001-2008

- Mount Placement:

-

Foot Mounted

- Bearing:

-

C ampU

Source Capability

- Source Capability:

- 500 Unit/Units for each Thirty day period

Packaging Shipping

- Packaging Information

- Normal wood situation

- Port

- Ningbo Port, Zhejiang Port

- Picture Illustration:

-

Lead Time

: -

Quantity(Units) 1 – one >1 Est. Time(times) 30 To be negotiated

Online Customization

Gearbox B Helical Bevel Electrical energy Electricity Reducer bevel gearbox for concrete mixer vehicle gearbox for tricycle diesel motor gear

Product Description

1) Output speed: 1.seven~1200r/min

two) Output torque: up to forty seven,000N.m

three) Motor electrical power: 2.fifty two~5366kW

4) Mounted type: foot-mounted ,flange-mounted, axis mounted, shrink mounted

|

Merchandise Name |

H/B collection substantial power velocity equipment reducer industrial gearbox for concrete mixer |

|

Housing nbspMaterial |

HT 250 Forged Iron |

|

Equipment Content |

20CrMnTi |

|

Shaft Substance nbsp |

20CrMnTi |

|

Gear Processing |

Grinding complete by HOFLER Grinding Machines |

|

Colour |

Custom-made |

|

Noise Examination |

Bellow 65dB |

|

Guarantee |

one calendar year |

Certifications

nbsp nbsp

nbsp

nbsp

Trade Exhibits

nbsp nbsp nbsp nbsp nbsp nbsp

nbsp nbsp nbsp

nbsp

At any time-electrical power

Packing Specifics nbsp: nbspStandard carton/Pallet/Standard wood case

Shipping Specifics : nbsp15-30 working days on payment

nbsp

Firm Information

nbsp

Relevant Merchandise

nbsp

You can click on the image to search other items.

nbsp

nbsp

Precision Planetary gearbox

| Precision Planetary gearbox | Robot RV gearbox pace reducer |

| Personalized produced Non-standard Gearbox | UDL Collection Variator |

| PYZ Sequence Helical Tooth Shaft Mounted Reducer | 8000 Sequence Cycloidal Reducer |

| SLT Sequence nbsp Spiral Bevel Gearbox | SLSWL Collection Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Sequence Substantial Energy Reducer |

| NMRV Collection Worm Reducer | BKM Collection Helical-hypoid Reducer |

| SLRC Sequence Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

| SLXG Collection Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Sequence Helical Reducer | AC/DC Motor |

nbsp

FAQ

nbsp

one.Payment Phrase: TT, L/C

nbsp

2.Shipping time: about nbsp30 days from receive payment. nbsp

nbsp

three.We take custom-made items as per your specific requirement.

nbsp

4.Guidelines for the Choice:Normally we can choose one particular device which is suitable for you with some informations from you,these kinds of as ratio/motor velocity/mounting dimension/ out torque and so on. nbsp

nbsp

5.If the minimum buy amount is in excessive of $10000, there are preferential.

nbsp

Q1: What details should I inform you to affirm the item?

A:Design/Measurement, Transmission Ratio, Shaft instructions amp Order quantity.

nbsp

Q2: What can i do if I will not know which 1 I need?

A:Dont worry, Send as much data as you can, our group will aid you discover the appropriate 1 you are seeking for.

nbsp

Q3: What is your item guarantee period?

A:We offer a single 12 months warranty given that the vessel departure day remaining China.

nbsp

Q4: Are you buying and selling company or company ?

A: We are manufacturing facility.

nbsp

Qfive: How prolonged is your supply time?

A: Normally it is five-10 times if the products are in stock. or it is fifteen-twenty days if the goods are not in stock, it is in accordance to amount.

nbsp

Q6: Do you provide samples ? is it totally free or extra ?

A: Sure, we could supply the sample for totally free charge but do not pay out the expense of freight.

nbsp

Qseven: What is your conditions of payment ?

A: Payment lt=1000USD, one hundred% in advance. Payment gt=1000USD, 30% T/T in progress ,harmony just before shippment.

nbsp

If you have any other questions, you should truly feel totally free to get in touch with us as demonstrated below, you can click on the impression beneath to speak to me straight.

Speak to Us

nbsp

NMRV-130 Manufacturing plant worm reduction gearbox mortar mixer gearbox gear

We can source a complete-variety of energy transmission items like chains, sprockets and plate wheels, pulleys, gearboxes, motors, couplings, gears and racks. EPG is a professional company and exporter that is involved with the style, growth and generation. The new goods contain a collection of substantial-tech and substantial high quality chains and sprockets and gears, this kind of as chains and gearboxes for agricultural machineries, metallurgical chains, escalator phase-chains, higher-pace tooth chains, timing chains, self-lubrication chains, between which have type substantial pace tooth chain for auto branch dynamic box and aerial chains fill in the blanks of chain in China.

Overview

Fast Information

- Location of Origin:Zhejiang, China

- Model Name:

-

OEM

- Gearing Arrangement:

-

Worm

- Output Torque:

-

thirteen-1379

- Enter Speed:

-

1400(4pole)

- Output Velocity:

-

fourteen-187

- Solution identify:

-

Velocity gearbox

- Ratio:

-

seven.five,ten,15,twenty,twenty five,30,forty,50,sixty,eighty,a hundred.

Offer Potential

- Provide Capability:

- ten thousand Set/Sets for each Month

Packaging Shipping and delivery

- Packaging Specifics

- standard export packing

- Port

- Zhejiang/ningbo

On the internet Customization

nbsp

Solution Description

Characteristics:

We generate WP series and RV sequence worm pace reducer,Single ,double and common pace reducer.

one nbsp Higher good quality, It adopts difficult tooth equipment with high precision

two nbsp Big output torque,steady transmission with reduced sounds

3 nbsp Substantial heat-radiating effectiveness,classy form,tough services existence 4,Suited for omni-bearing installation

5 nbsp Minimal sound and smooth running

6 nbsp Worm generate uses hollow flank worm

7 nbsp High loading potential, low in temperature rise and the lengthy helpful lifestyle

8 nbsp Few variation among transmission ratio rate, I = six~13800

9 nbsp Compact framework, tiny size, handy servicing

10 Are based mostly the exclusive modulation mix system, so its convenient for them to in shape all sorts of motors or to link with other power enter. The exact same type of reducer can match motors with diverse electricity, so that its possible for different varieties of machines to mix or join.

nbsp

nbsp The gearboxes can be used to several industrial spot, this kind of as Metallurgical, mines, lifting, transportation, petrochemical, development, textile, pharmaceutical, food, environmental, light electric powered, plastic machine, paper, parking products and so on. Our technological engineers can choose model for you in accordance to your Request, and we also can offer our factory catalogue for your reference.

nbsp

Item nbspsummary nbsp nbsp nbsp NMRV nbspseries nbspworm nbspgear nbspreducer nbspis nbspa nbspnew nbspgeneration nbspof nbspproducts nbspcombining nbspthe nbspinternational nbspadvanced nbsptechnology nbspbased nbspon nbspthe nbsporiginal nbspWP nbspseries nbspproducts.It adopts nbspadvanced nbspsquare nbspbox nbspstructure,high nbspquality nbspdie-casted nbspAluminum nbspalloy.It nbsphas nbspsmall nbspvolume,light-weight nbspweight,higher nbspstrength,heat nbspdissipation,eye-catching nbspand nbspdurable.

The nbspreducer nbsphas nbspbig nbspoutput nbsptorque,sleek nbsptransmission nbspand nbsplow nbspnoise.It adopts nbspall-shut nbspstructure,good nbspsealing,free nbspof nbspmaintenance,can nbspadapt nbspto nbspcomprehensive nbspinstallation

nbsp

|

Worm nbspGear nbspSpeed nbspReducer/ nbspgearbox nbsp |

|

|

Product |

NMRV25/thirty/40/fifty/63/75/ninety/a hundred/one hundred thirty/a hundred and fifty |

|

Ratio |

7.5,10,fifteen,twenty,twenty five,thirty,forty,fifty,sixty,eighty,one hundred. |

|

Colour |

Blue(RAL5010)/Silver nbspgrey nbsp(RAL9006) nbspOr nbspOn nbspCustomer nbspRequest |

|

Materials |

Aluminum nbspalloy Worm nbspwheel: nbspAluminum nbspBronze nbspor nbspZinc nbspBronze Worm nbspshaft: nbsp20CrMn nbspTi Output nbspShaft: nbspsteel-45# |

|

Packing |

Carton, nbspHoney nbspComb nbspCarton, nbspWooden nbspCase nbspwith nbspwooden nbsppallet |

|

Warranty |

one nbspYear |

|

Input nbspPower |

.09kw,.18kw,1.1KW,1.5KW,2.2KW,3KW,4KW,five.5KW,7.5KW,11Kw nbspand nbspso nbspon |

|

Usages |

Industrial nbspMachine: nbspFood nbspStuff, nbspCeramics, nbspCHEMICAL, nbspPacking, nbspDyeing,Wood nbspworking, nbspGlass. |

|

IEC nbspFlange |

IEC nbspstandard nbspflange nbspor nbspon nbspcustomer nbsprequest |

|

Lubricant |

Synthetic nbspoil nbspor nbspworm nbspgear nbspoil |

Solution Groups

nbsp

Organization Introduction

nbsp

Packaging

nbsp

FAQ

one. Q: What is actually nbsptype of your firm.

nbsp nbsp nbsp nbsp nbspA: We are producer.

nbsp2. Q: what should I provide when I choose gearbox/pace reducer?

nbsp nbsp nbspA: one) load problem

nbsp nbsp nbsp nbsp nbsp2) velocity of rotation or pace ratio(combination with combine speed reducer can get added minimal out putting rotational speed)

nbsp nbsp nbsp nbsp nbsp3) work circumstance(temperature, humidty,corrosion etc.)

nbsp nbsp nbsp nbsp nbsp4) place of set up

3. nbspQ: nbspHow nbsplong nbspdose nbspit nbsptake nbspto nbspfinish nbspmy nbsporder?

nbsp nbsp nbsp nbspA: nbspIt nbspdepends nbspon nbspyour nbspquantity. nbspGenerally nbsp25days nbspfor nbspone nbsp20GP, nbsp35days nbspfor nbspone nbsp40HQ.

4. Q: How nbspcan nbspi nbspknow nbspthe nbspprocess nbspof nbspmy nbsporder?

nbsp nbsp nbsp nbsp nbsp nbspA: nbspDetailed nbsppicture nbspof nbspthe nbspproduction nbspprocess nbspwill nbspbe nbspsent nbspto nbspyou nbspto nbspconfirm nbspbefore nbspshipping. nbsp

nbsp nbsp nbsp nbsp nbsp nbsp nbsp nbsp Consummation nbspQC nbspsystem nbspmakes nbspit nbsppossible nbspto nbspoffer nbspyou nbspreliable nbspquality

nbsp

nbsp

Speak to us

nbsp

Back to property

nbsp

SWL5 China screw actuator power screw jack mechanical worm gear screw jacks hollow shaft motor reducer gear motor for concrete mixer

With comprehensive requirments, we can also create your specific developed item. EPG is a skilled producer and exporter that is worried with the style, improvement and creation. We have exported our merchandise to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the United states, Canada, and many others.

Overview

Quick Details

- Relevant Industries:

-

Lodges, Garment Stores, Constructing Substance Retailers, Producing Plant, Machinery Mend Outlets, Foods amp Beverage Factory, Farms, Restaurant, House Use, Retail, Design works nbsp, Energy amp Mining, Foodstuff amp Beverage Outlets, Advertising Business

- Gearing Arrangement:

-

Worm

- Output Torque:

-

50~2300Nm

- Enter Speed:

-

1400rpm

- Output Speed:

-

fourteen-280rpm

- Place of Origin:Zhejiang, China

- Brand name Identify:

-

OEM

- Certification:

-

ISO9001-2008

- Lifting Ability:

-

As ask for

- Lifting Peak(mm):

-

As ask for

- All round Width(mm):

-

As request

- Equipment substance:

-

Lower carbon higher alloy metal

- Warmth remedy:

-

Carburising, quenching, gear grinding

- Diameter amp Length of Screw:

-

Created as ask for

- Bearing:

-

C ampU

- gear precision quality:

-

din 4

Packaging Shipping

- Promoting Units:

- Single merchandise

- Single deal dimensions: nbsp

- 40X50X20 cm

- One gross fat:

- forty.000 kg

- Deal Kind:

- Standard exporting package

-

Guide Time

: -

Quantity(Models) 1 – one >1 Est. Time(times) 10 To be negotiated

On the web Customization

Video clip Description

Item Description

screw actuator energy screw jack mechanical worm equipment screw jacks hollow shaft motor reducer gear motor for concrete mixer

nbsp

Edge:

SWL Worm-bolt lifter nbsphas the features of compacted structure, light-weight and portable, versatile, reliable, prolonged services lifestyle, effortless to installation, and self-locking whilst cease.

nbsp

Software Industries:

nbspSWL series screw jacks are broadly utilised in nbspindustries this sort of as metallurgy,mining,hoisting and transportation, electrical electrical power,vitality source, construction and creating material,light business and visitors nbspindustry

nbsp

nbsp

nbsp

nbsp

nbsp

nbsp

nbsp

nbsp

Certifications

nbsp nbsp

nbsp

nbsp

Trade Shows

nbsp nbsp nbsp nbsp nbsp nbsp

nbsp nbsp nbsp

nbsp

At any time-power

Packing Particulars nbsp: nbspStandard carton/Pallet/Common picket circumstance

Shipping Information : nbsp15-30 functioning times on payment

nbsp

Company Details

nbsp

other collection solution

| Precision Planetary gearbox | Robotic RV gearbox pace reducer |

| Personalized produced Non-normal Gearbox | UDL Sequence Variator |

| PYZ Collection Helical Tooth Shaft Mounted Reducer | 8000 Collection Cycloidal Reducer |

| SLT Sequence nbsp Spiral Bevel Gearbox | SLSWL Sequence Worm Screw Jack |

| SLP Sequence Planetary Reducer | SLH/SLB Collection Higher Electricity Reducer |

| NMRV Series Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

| SLXG Collection Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Collection Helical Reducer | nbsp |

Connected Merchandise

nbsp

nbsp

Get in touch with

Remember to scan code include me!

+8613091920617

SLR factory Outlet r series reducer gear belt drive weld reducer reducer gearbox nmrv planetary gearbox planetary planetary gearbox mixer

We offer you OEM services. Our item selection involves all varieties of helical gear, spur gear, bevel equipment, equipment rack, worm equipment, sprockets,chains, bearings. Hangzhou EPG Co.,Ltd. , was founded in November, 1997. With its 5 wholly owned subsidiaries.

Overview

Fast Particulars

- Applicable Industries:

-

Lodges, Garment Stores, Developing Content Shops, Producing Plant, Machinery Restore Stores, Foodstuff amp Beverage Manufacturing facility, Farms, Restaurant, Home Use, Retail, Foods Store, Printing Stores, Development works nbsp, Power amp Mining, Foodstuff amp Beverage Outlets, Marketing Company

- Spot of Origin:Zhejiang, China

- Brand Title:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

800~100000N.m

- Enter Speed:

-

1400rpm

- Output Velocity:

-

fourteen-280rpm

- Ratio:

-

7.5~100

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

C ampU,LYC,SKF

Offer Ability

- Offer Ability:

- one thousand Device/Models for each Thirty day period

Packaging Shipping

- Packaging Details

- Picket containers , Cantons packed in 1 pallet

- Port

- Ningbo Port, Zhejiang Port

-

Direct Time

: -

Quantity(Models) one – fifteen >15 Est. Time(times) 15 To be negotiated

On-line Customization

Item Description

nbsp

R series helical abb geared motors gearbox reducer nbsphas the attributes of higher versatility,

good combination and large loading capability, alongside with other deserves this kind of as simple to achieve various transmission ratios,

high efficiency, low vibrationand substantial permissible axis radial load.

This collection can not only be merged with a variety of varieties of reducers and variators and fulfill the demands,

but also beadvantage of localization of associated transmission tools.

one) Output speed: .6~1,028rpm

2) Output torque: up to 18,000N.m

3) Motor power: .18~160kW

4) Mounted sort: foot-mounted and flange-mounted mounting

|

Equipment Substance |

20CrMnTi nbsp |

||

|

Case Materials |

HT250 |

||

|

Shaft Materials nbsp |

20CrMnTi |

||

|

Gear Processing |

Grinding finish by HOFLER Grinding Machines |

||

|

Coloration nbsp |

Tailored |

||

|

Sound Test |

Bellow 65dB |

||

Certifications

nbsp nbsp

nbsp

nbsp

Trade Demonstrates

nbsp nbsp nbsp nbsp nbsp nbsp

nbsp nbsp nbsp

nbsp

Ever-energy

Packing Details nbsp: nbspStandard carton/Pallet/Normal wood circumstance

Shipping Specifics : nbsp15-30 doing work days upon payment

nbsp

Company Data

nbsp

Get in touch with Details

nbsp

Connected Items

other sequence item

| Precision Planetary gearbox | Robotic RV gearbox velocity reducer |

| Custom made created Non-common Gearbox | UDL Collection Variator |

| PYZ Series Helical Tooth Shaft Mounted Reducer | 8000 Collection Cycloidal Reducer |

| SLT Series nbsp Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Collection Planetary Reducer | SLH/SLB Series High Energy Reducer |

| NMRV Sequence Worm Reducer | BKM Sequence Helical-hypoid Reducer |

| SLRC Collection Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

| SLXG Sequence Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Collection Helical Reducer | nbsp |