Product Description

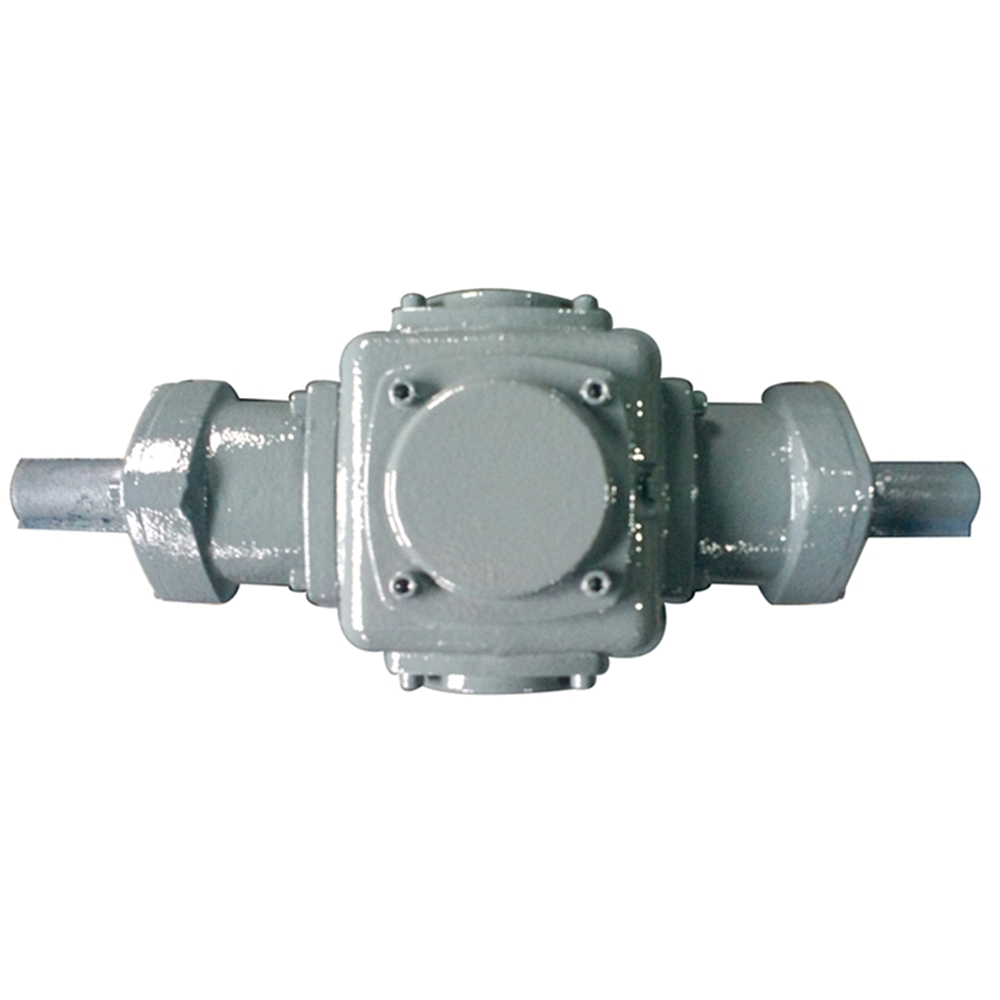

CZPT Small Size and Light Weight JT15 Spiral Bevel Industrial Gearboxes are available in numerous configurations to meet our customers’ specific requirements. These right angle gearboxes provide outputs at 90° from the input with superior performance, durability, and versatility for nearly any power transfer application.

Small Size and Light Weight JT15 Spiral Bevel Industrial Gearboxes Features:

1. Maximum allowable torque 28.1 Nm, Maximum allowable power 1.79 kw, maximum allowable input or output speed 156567X3, registered Capital 500000CNY) is a leading manufacturer and supplier of Screw Jacks (Mechanical Actuators), Bevel Gearboxes, Lifting Systems, Electric Linear Actuators, Gearmotors and Speed Reducers, Others Linear Motion and Power Transmission Products in China. We are located in Chang An, Xihu (West Lake) Dis. guan, Guang dong in China. We are an audited professional manufacturer and supplier by SGS (Serial NO.: QIP-ASI192186) and BV (Serial NO.: MIC-ASR257162) organizations. We have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, and consistently provide the customers with the best engineered solution for precision linear actuation, power transmission and mechanical jacking systems. CZPT Industries guarantees quality, reliability, performance and value for today’s demanding industrial applications.

Company Advantages

* One of the biggest orders with 1750 units screw lift jacks.

* Standard products with 2D Drawings(DXF, DWG, PDF) and 3D CAD Model(STEP).

* 100% quality assured with double quality inspections. Original Inspection Reports, Operation Manual, and Book Catalogue are put into the packages.

* 100% safety transportation with strong standard export plywood cases materials (free fumigation).

* International standard materials for all standard products.

* Custom design available, OEM service available, Free engineering advice and Customer label available.

Products List

* Manual Screw Jacks

* Electric Screw Jacks

* Screw Jacks Series:

Cubic Screw Jack JTC Series, Machine Screw Jack JTW Series, Trapezoidal Screw Jack JT Series, Worm Screw Jack JTM Series, Stainless Steel Screw Jack JSS Series, Through Hole Screw Jack JTH Series, Ball Screw Jack JTB Series, Cubic Ball Screw Jack JTD Series, Bevel Gear Screw Jack JTS Series, and Electric Cylinder JTE Series.

* Bevel Gearboxes Series:

Cubic Bevel Gearbox JTP Series, Hollow Shaft Gearbox JTPH Series, Input Flange Gearbox JTPF Series, Input Flange and Hollow shaft Gearbox JTPG Series, Stainless Steel Gearbox JTP Series, Aluminum Gearbox JTA Series, and Bevel Gearboxes JT Series.

* Screw Jack Lifting Systems and Accessories:

2jacks lifting system, 3jacks lifting system, 4jacks lifting system, 6jacks lifting system, 8jacks lifting system……14jacks lifting system. Lifting systems accessories cover ac, dc motors, geared motors, servo motors, stepper motors, handwheels, couplings, universal joints, telescopic universal joints, connecting shafts, cardan shafts, limit switches, proximity switches, safety nut, travel nut, rod ends, stop nuts, pillow block bearings, flange blocks, motor flange nema or iec, encoder, potentiometer, frequency converter, position indicators, trunnion plate, and trunnion mounting brackets.

* Electric Linear Actuators Series:

Electro Mechanical Actuators LA Series, Electro Mechanical Actuators LAP Series.

* Gear Reducers Series:

Helical Gear Reducers R Series, Helical Bevel Gear Reducers K Series, Parallel Shaft Helical Gear Reducers F Series, Helical Worm Gear Reducers S Series, Helical Gear Motor GMH/GMV Series, and Worm Gear Reducers NMRV Series.

Customers Distribution Countries

* American Countries: United States, Mexico, Canada, Chile, Argentina, Xihu (West Lake) Dis.via, Brazil, Colombia, Guatemala, Honduras, Panama, Peru.

* European Countries: Germany, France, United Kingdom, Italy, Spain, Poland, Romania, Netherlands, Belgium, Greece, Czech Republic, Portugal, Sweden, Hungary, Austria, Switzerland, Bulgaria, Denmark, Finland, Slovakia, Norway, Ireland, Georgia, Slovenia.

* Asian Countries: Malaysia, Indonesia, Singapore, Philippines, Vietnam, Thailand, India, Israel, Cambodia, Myanmar, Sri Lanka, Maldives, Pakistan, Iran, Turkey, Jordan, Saudi Arabia, Yemen, Oman, United Arab Emirates, Qatar, Georgia, Armenia.

* Oceanian Countries: Australia, New Zealand.

* African Countries: Egypt, Ethiopia, Nigeria, South Africa, Zambia, Mozambique.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | T Type, L Type |

| Hardness: | Hardened Tooth Surface |

| Installation: | Universal Mounting |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

Benefits of Using a High-Quality Agricultural Gearbox

If you are in the market for an agricultural gearbox, then you should keep a few things in mind. A high-quality agricultural gearbox will have innovative technology and features to make your life easier. Despite all these features, you should not compromise on the ease of use. Before buying any agricultural gearbox, make sure that you are familiar with its features and functions. Read on to learn more. This article will help you choose the perfect gearbox for your specific needs.

Bevel gearboxes

Agricultural gearboxes play a vital role in the production of food. If they do not work properly, the demand for food will rise significantly, causing costly downtime and a failure to meet production goals. In addition, the gears can be worn out and cause significant losses for farmers. In such cases, high-quality gearboxes are essential for the production of food. Here are some benefits of using a high-quality bevel gearbox for agricultural applications:

Bevel gearboxes feature enclosed spiral or straight bevel gears to transmit rotational power to the drive shaft. Bevel gear drives are available in various horsepower capacities and ratios, and they can be installed at different angles. For example, CZPT Gearbox offers bevel gear drives whose bevel angles can reach 68 degrees for grain carts and 50 degrees for portable grain augers. These are suitable for agricultural machinery applications such as combines, tractors, and grain carts.

Premium Bevel gearboxes are available in many sizes, and are a cost-effective way to replace worn-out gears. Premium gearmotors are designed with a low backlash and are quiet while transferring power. The bevel gears are crafted from hardened stainless steel and feature non-magnetic shafts. Agricultural gearboxes are available in many types, and you can buy one that matches the exact specifications of your machinery.

A wide variety of applications for bevel gearboxes in agricultural machinery is important. Most implements and tractors have PTOs, which transmit high torque but only at slower speeds than standard 540 or 1000 rpm. A bevel gearbox is needed for these high-demand situations. They are not only used in agriculture, but are also used in wheel drives and massive torque low-speed applications.

Closed-loop seals

The installation of closed-loop seals in agricultural gearboxes has a number of advantages. For one thing, they isolate the gearbox from the atmosphere, which is essential for the safety of the equipment. A desiccant breather is not enough to protect the gearbox from water damage; closed-loop seals prevent water from entering the gearbox. In fact, a closed-loop elastomeric seal can prevent up to 90% of leakage.

The CZPT gearbox is available on the entire line of CZPT irrigation systems. It is designed to turn with the drive shaft, and it places seal lips inside a cavity filled with a high-temperature grease, which minimizes the possibility of dislocation. In addition, the CZPT gearbox features a sealed housing surrounded by an eight-year warranty. It is also compatible with mobile irrigation systems.

An agricultural gearbox is vital for the whole food chain, from the fields to the table. Even a small amount of downtime can affect production. It’s important to invest in a gearbox that won’t break down easily. A well-designed agricultural gearbox will last for decades and should be easy to access for maintenance. The following factors are important to consider when purchasing a gearbox.

A positive gear ratio in an agricultural gearbox is a prerequisite for smooth operation. In addition, closed-loop seals in agricultural gearboxes will prevent the wheels from slipping and provide a positive gear ratio. Another crucial component of an agricultural gearbox is a locking differential. This system helps to prevent the wheels from slipping, even in high-dust environments. The ZHEJIANG HONGYE AGRICULTURAL EQUIPMENT CO.,LTD company is a renowned manufacturer of agricultural gearboxes in China and has a pan-India presence. The company has been in the industry for over 15 years, and their products are renowned for their durability and performance.

Robustness

Robustness of agricultural gearbox is important for the agricultural industry. Low-speed equipment is prone to mechanical overload under demanding operating conditions, which can cause premature component wear and reduce equipment longevity. Especially susceptible are components that are belt-driven, chain-driven, or fan-driven. Proper installation of system components will extend the life of these heavy-duty machines and reduce the risk of costly downtime. To improve efficiency and productivity, agricultural gearboxes are used in these systems.

Agricultural gearboxes are used in machinery in remote and outdoor locations. They must be resilient to the various harsh conditions they face, including frequent washing down and constant moisture. They must also operate near-constantly, particularly during harvest time. Agricultural gearboxes must also be hygienic and reliable, ensuring that they serve their purpose without any complications. As a result, they must be robust and reliable.

Modern industrial activity seeks efficiency gains and reduced weight. The ruggedness of agricultural gearboxes has increased significantly over the past few decades. However, this efficiency is accompanied by an increased need for robust protection and increased energy efficiency. Synthetic base stocks can provide CZPT protection for all gearboxes and extend drain intervals. However, high maintenance costs and the impact of the COVID-19 pandemic may impede growth.

Durability

Agricultural gearboxes play a major role in the production of food and are essential in the entire process. With the increasing population and increasing need for food, crop cycles will get shorter and heavier, and the impact on gearboxes will only grow. As a result, farmers will need more quality replacement gearboxes to ensure the productivity of their operations. So, what makes an agricultural gearbox durable? Here are some important factors to consider when purchasing a quality unit.

Agricultural PTO gearboxes can be dual or single shaft models. Dual-shaft designs divert the power of the engine to an additional output shaft, while axle-facing designs mount between the engine and transmission and receive drive directly from the engine shaft. In this latter design, full engine power is transferred to the PTO, but the driveline needs to be modified to accommodate the additional output shaft. This means that the optimum gearbox size should be chosen depending on the use of the machine.

The transmission operating parameters of 44 tractors were tracked over a year. Different failure modes were identified, the load amplitude was calculated for each component, and the frequency of failure was calculated. In addition, a severe-damage profile was estimated from statistical analysis. Finally, the accelerated test schedule was determined by using an optimisation technique. It was set up to maximize the torque applied to each component. In addition to the transmission’s overall durability, the gear tooth breakage was also observed.

A durable agricultural PTO gearbox is an essential tractor component. CZPT Gearbox Company manufactures high-performance gear drives. They can reverse engineer an existing design or create a custom agricultural gearbox based on your specifications. Agricultural PTO gearboxes have many advantages over their manual counterparts. They allow a tractor to operate at the appropriate speed and torque without compromising the tractor’s performance. They can also reduce the output speed, allowing the machine to maintain the proper speed.

Cost

For optimum performance and reduced costs, a high-quality agricultural gearbox can help farmers make the most of their machines. An agricultural gearbox transmits power from the input shaft to the output shaft, facilitating changes in speed, direction, and rotation. The CZPT Gearbox Company is a leading manufacturer of high-performance agricultural gearboxes. Aside from offering a variety of standard gearboxes, engineers can custom-design and manufacture a gearbox for your specific needs.

With the CZPT marketplace, buyers from other countries can find a reliable, competitively priced Indian Agriculture Gearbox supplier. When selecting a supplier, buyers consider a range of factors, such as value for money, reliability, and past trade history. Agriculture Gearbox suppliers in India can be found in all major cities and states across the country. By choosing a distributor in India based on price and service quality, you can ensure your purchase will be of the highest quality and least costly.

While choosing an agricultural gearbox, look for one that is built to last. The functionality, mechanism, and materials of the device are all factors in determining how long a gearbox will work. Choose a long-lasting option so you won’t have to purchase a replacement for it every few years. Also, look for a low-maintenance option. A low-maintenance gearbox will save you money over time.

While it is possible to rebuild a gearbox on your own, it’s best to find a company that rebuilds gearboxes and parts. CZPT in New York will estimate the cost of rebuilding a gearbox for you. If you’re not sure how much it will cost to rebuild your agricultural gearbox, they’ll be happy to help you make a decision based on the details of your specific needs.

editor by CX 2024-03-28

China supplier F/K/S/F Series Coaxial Parallel Shaft Worm Gear, Right Angle Connected Spiral Bevel Helical Gear Reducer Gearbox gearbox design

Product Description

Product Description

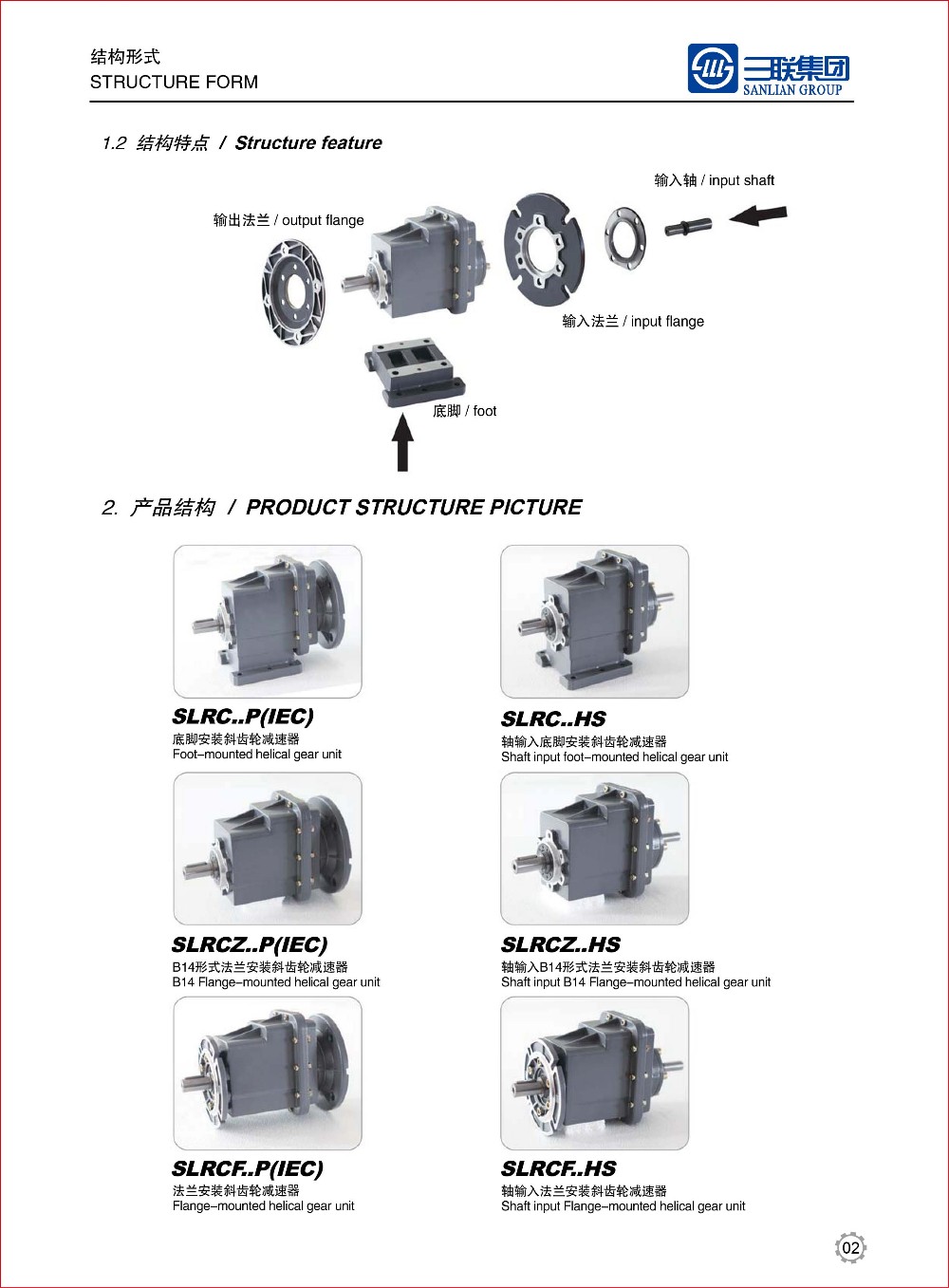

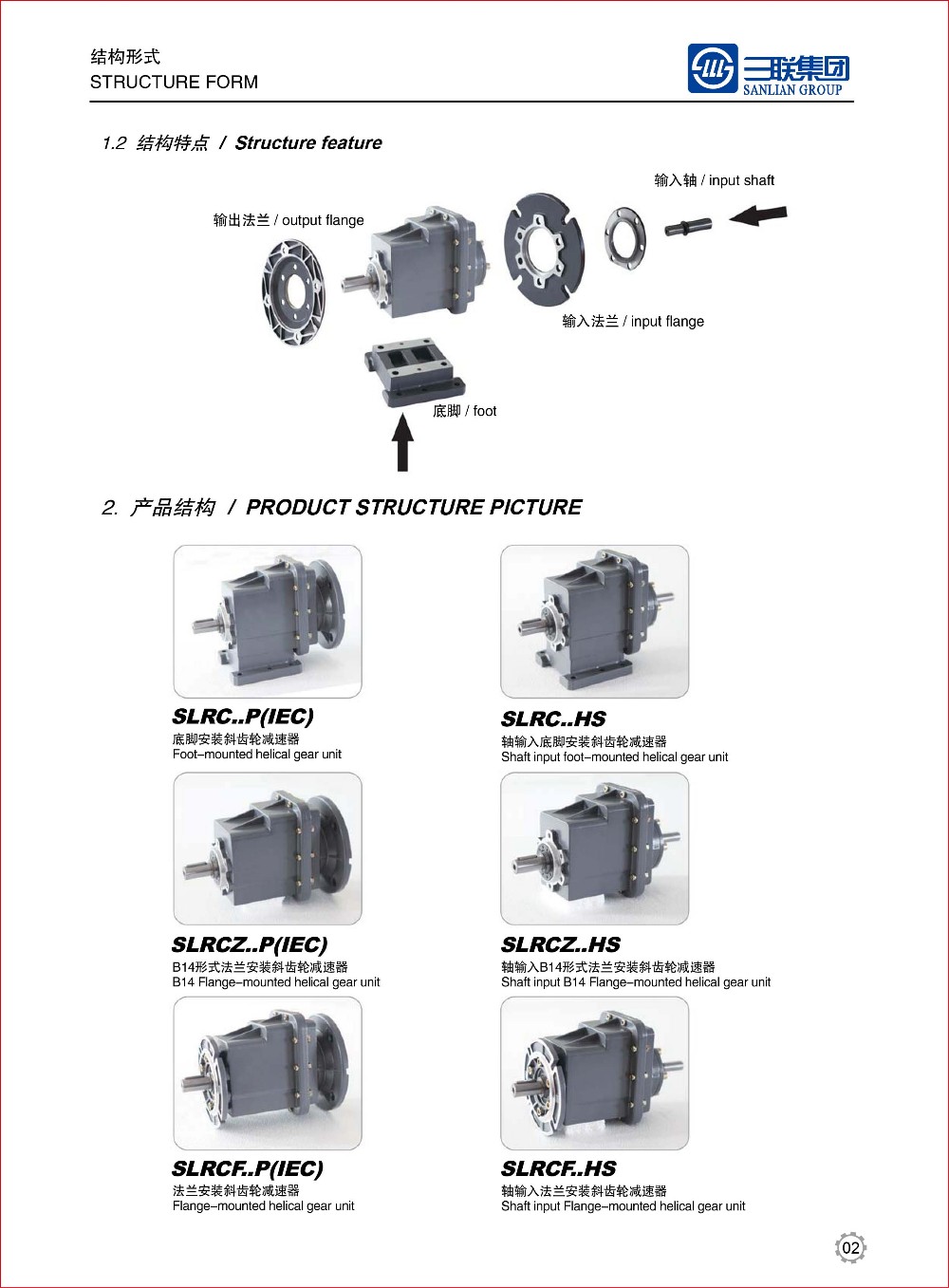

-K Series Helical Bevel Gearbox

K series gear reducer, manufactured according to international technical requirements, has a high scientific and technological content; Space saving, reliable and durable, high overload capacity, power up to 132KW; Low energy consumption, superior performance, reducer efficiency up to 95%

It is designed and manufactured on the basis of module combination system. There are a lot of motor combinations, installation forms and structural schemes. The transmission ratio is classified carefully to meet different operating conditions and realize electromechanical integration.

High transmission efficiency, low energy consumption and superior performance.

Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface is carburized, quenched and hardened, and the gear is finely ground. It features stable transmission, low noise, large bearing capacity, low temperature rise, and long service life. Performance and characteristics:

1. The gear is carburized and quenched with high-quality alloy, the hardness of the tooth surface is up to 60 ± 2hrc, and the grinding accuracy of the tooth surface is up to 5-6

2. The computer modification technology is used to pre modify the gear, which greatly improves the bearing capacity of the reducer

3. Complete modular structure design is adopted from the box to the internal gear, which is suitable for large-scale production and flexible selection

4. The standard reducer models are divided according to the form of decreasing torque. Compared with the traditional equal proportion division, they are more in line with customer requirements and avoid power waste

5. It is designed and manufactured by cad/cam to ensure the stability of quality

6. Multiple sealing structures are adopted to prevent oil leakage

7. Multi directional noise reduction measures to ensure the excellent low noise performance of the reducer

8. The installation mode of Liyi products is flexible, which makes it easy for customers to choose K57 reducer, K67 reducer, K77 reducer, K87 reducer, K97 reducer, KA87 reducer, KA97 reducer, KA107 reducer, KA127 reducer

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Marine, Agricultural Machinery, Car, Packing Machine, Food Process, Lift, Crane, Agita |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Samples: |

US$ 800/Piece

1 Piece(Min.Order) | |

|---|

Lubrication Practices for Extending the Lifespan of Agricultural Gearboxes

Proper lubrication is essential for ensuring the longevity and optimal performance of agricultural gearboxes. Here are some essential lubrication practices that can help extend the lifespan of these gearboxes:

- Choose the Right Lubricant: Select a high-quality lubricant specifically designed for gearboxes and agricultural machinery. Consider factors such as viscosity, temperature range, and load-bearing capacity to ensure compatibility with the gearbox’s operating conditions.

- Regular Inspection: Perform regular visual inspections of the gearbox and lubricant to check for signs of contamination, wear, or inadequate lubrication. Address any issues promptly to prevent further damage.

- Cleanliness: Maintain a clean environment around the gearbox to minimize the risk of dirt, debris, and moisture entering the gearbox housing. Contaminants can compromise the lubricant’s effectiveness and accelerate wear.

- Lubricant Level: Monitor and maintain the proper lubricant level in the gearbox. Insufficient lubrication can lead to increased friction and heat, causing premature wear and potential damage to gears and bearings.

- Replace Lubricant: Follow the manufacturer’s recommendations for lubricant change intervals. Over time, lubricants can degrade, lose their properties, and become contaminated. Regularly replacing the lubricant helps ensure optimal performance.

- Use Lubrication Schedule: Create a lubrication schedule based on the gearbox’s usage and operating conditions. Stick to the recommended intervals for applying or changing lubricant to prevent under-lubrication or over-lubrication.

- Appropriate Lubrication Method: Follow the manufacturer’s guidelines for the correct lubrication method, whether it’s through oil bath, grease, or automatic lubrication systems. Proper application ensures even distribution of lubricant across gear surfaces.

- Temperature Considerations: Be aware of temperature variations in your operating environment. Extreme temperatures can affect lubricant viscosity and performance. Choose a lubricant that can handle the temperature range of your equipment.

- Expert Advice: Consult the gearbox manufacturer or a lubrication specialist to determine the best lubrication practices for your specific agricultural gearbox model and application.

By adhering to these lubrication practices, farmers can maximize the lifespan of their agricultural gearboxes, minimize downtime, and ensure efficient and reliable operation of their equipment.

Specific Safety Precautions for Agricultural Gearbox Operation

Operating agricultural machinery with gearboxes requires careful attention to safety to prevent accidents and ensure the well-being of operators and bystanders. Here are some specific safety precautions associated with agricultural gearbox operation:

- Read the Manual: Familiarize yourself with the manufacturer’s manual for the specific gearbox and machinery. It provides valuable information about proper operation, maintenance, and safety guidelines.

- Proper Training: Ensure that operators are trained in the safe operation of the machinery, including how to engage and disengage the gearbox, adjust speeds, and handle emergencies.

- Protective Gear: Operators should wear appropriate protective gear, such as helmets, gloves, safety goggles, and sturdy footwear, to reduce the risk of injury from debris, moving parts, or other hazards.

- Clear Workspace: Before operating the machinery, clear the area of obstacles, debris, and bystanders. Ensure a safe distance between the machinery and people.

- Secure Attachments: If the gearbox is used in conjunction with attachments, ensure that they are properly secured and mounted according to manufacturer guidelines to prevent detachment during operation.

- Engage Safely: Engage the gearbox and start the machinery only after ensuring that all personnel are at a safe distance and that the machinery is on stable ground.

- Avoid Loose Clothing: Operators should avoid wearing loose clothing or accessories that could get caught in moving parts.

- Emergency Stops: Familiarize yourself with the location of emergency stop buttons and switches on the machinery and be prepared to use them if needed.

- Regular Maintenance: Perform routine maintenance checks on the gearbox and machinery to ensure that all components are in proper working condition. Replace worn parts and lubricate components as recommended by the manufacturer.

- Shut Down Properly: When finishing a task, disengage the gearbox, shut off the machinery, and engage any safety locks to prevent accidental starts.

Following these safety precautions can greatly reduce the risk of accidents and injuries when operating agricultural machinery with gearboxes. Always prioritize safety to create a secure working environment for everyone involved.

Maintenance Requirements for Agricultural Gearboxes

Maintaining agricultural gearboxes is crucial to ensure the smooth and efficient operation of farming equipment. Proper maintenance helps extend the lifespan of gearboxes and prevents costly breakdowns. Here are the key maintenance requirements:

- Regular Inspections: Conduct routine visual inspections to check for signs of wear, damage, leaks, or misalignment. Regularly inspect gear teeth, seals, and bearings for any issues.

- Lubrication: Proper lubrication is essential to minimize friction and wear in gearboxes. Follow the manufacturer’s guidelines for the type of lubricant to use and the recommended intervals for lubrication.

- Lubricant Checks: Monitor the gearbox’s lubricant levels and quality regularly. Replace or replenish lubricants as needed, and ensure that contaminants are kept out of the lubrication system.

- Tightening Bolts and Fasteners: Check and tighten bolts, nuts, and fasteners to prevent loosening due to vibrations during operation. Loose components can lead to misalignment and premature wear.

- Seal Inspection: Examine seals for leaks and proper sealing. Damaged or worn seals should be replaced promptly to prevent lubricant leakage and the ingress of contaminants.

- Cleaning: Keep gearboxes clean by removing dirt, debris, and residue. Regular cleaning prevents abrasive particles from entering the gearbox and causing damage.

- Alignment: Ensure that gearboxes are properly aligned with connected components, such as shafts and couplings. Misalignment can lead to increased wear and reduced efficiency.

- Temperature Monitoring: Monitor the operating temperature of the gearbox. Abnormal temperature increases may indicate issues like overloading or insufficient lubrication.

- Filter Replacement: If the gearbox has a filtration system, regularly replace or clean the filters to prevent contaminants from entering the gearbox.

- Expert Inspection: Periodically have gearboxes inspected by qualified technicians. They can identify potential problems that may not be visible during routine inspections.

Adhering to these maintenance requirements ensures that agricultural gearboxes remain in optimal condition and contribute to the reliability and efficiency of farming equipment. Regular maintenance not only prevents unexpected downtime but also prolongs the service life of the gearboxes, ultimately benefiting the productivity of agricultural operations.

editor by CX 2024-02-04

China Best Sales Right Angle Cubic Spiral Bevel Gearbox for Servo Motor sequential gearbox

Product Description

For over 12 years, spiral bevel gearboxes from SIJIE have been the market leader for high-quality, reliable, versatile right-angle gearboxes.

We can also manufacture a special bevel gearbox to fit all your demands of the application.

SIJIE spiral bevel gearboxes are offered in 8 types of housing sizes and 6 types of gear ratios, which can be constructed with lots of shaft configurations and oriented in any direction to easily integrate into your machine design.

All the shaft configurations are suitable for Casting iron, stainless steel, and aluminum version bevel gearboxes.

Spiral Bevel Gearbox Specifications

| Model | Input Speed (RPM) | Gear Ratio 1:1 | Gear Ratio 2:1 | Gear Ratio 3:1 | Gear Ratio 4:1 | Gear Ratio 5:1 | |||||

| Power | Torque | Power | Torque | Power | Torque | Power | Torque | Power | Torque | ||

| ( KW ) | ( N.m ) | ( KW ) | ( N.m ) | ( KW ) | ( N.m ) | ( KW ) | ( N.m ) | ( KW ) | ( N.m ) | ||

| SJV-090 | 2000 | 7.55 | 33.6 | 4.2 | 38.57 | 2.85 | 40.39 | 2.15 | 39.76 | 1.4 | 34.56 |

| 1500 | 6 | 38.2 | 3.35 | 42.66 | 2.2 | 42.02 | 1.65 | 42.02 | 1.1 | 35.02 | |

| 1000 | 4.3 | 41.07 | 2.35 | 44.89 | 1.5 | 43.02 | 1.15 | 43.93 | 0.75 | 35.81 | |

| 750 | 3.4 | 43.29 | 1.8 | 45.84 | 1.2 | 45.84 | 0.87 | 44.19 | 0.58 | 36.93 | |

| SJV-110 | 2000 | 13.8 | 63 | 7.9 | 72 | 5.6 | 80 | 3.75 | 70.1 | 2.95 | 71.3 |

| 1500 | 11 | 70 | 6.3 | 80.2 | 4.45 | 85 | 2.9 | 73.9 | 2.35 | 74.8 | |

| 1000 | 7.87 | 75 | 4.45 | 85 | 3.1 | 88.8 | 2 | 76.4 | 1.6 | 76.4 | |

| 750 | 6.15 | 78.3 | 3.45 | 87.9 | 2.4 | 91.7 | 1.55 | 78.9 | 1.25 | 79.6 | |

| SJV140 | 2000 | 29.9 | 128.6 | 14.1 | 133.3 | 10.1 | 136.8 | 6.8 | 125.3 | 5.05 | 115.2 |

| 1500 | 23.9 | 152.2 | 11.1 | 141.3 | 7.95 | 151.8 | 5.3 | 135 | 3.95 | 125.7 | |

| 1000 | 17.2 | 164.3 | 7.85 | 149.9 | 5.6 | 160.4 | 3.75 | 143.3 | 2.75 | 131.3 | |

| 750 | 13.4 | 170.6 | 6.2 | 157.9 | 4.4 | 168.1 | 2.95 | 150.3 | 2.1 | 133.7 | |

| SJV-170 | 2000 | 49.2 | 180.1 | 26.2 | 224.7 | 18.2 | 235.2 | 10.5 | 179.5 | 8.05 | 170.9 |

| 1500 | 39.3 | 250.2 | 20.8 | 264.9 | 14.4 | 275 | 8.4 | 213.9 | 6.45 | 205.3 | |

| 1000 | 28.8 | 275 | 14.9 | 284.6 | 10.1 | 289.4 | 5.9 | 225.4 | 4.5 | 214.9 | |

| 750 | 22.8 | 290.3 | 11.6 | 295.4 | 7.8 | 298 | 4.55 | 231.7 | 3.45 | 219.7 | |

| SJV-210 | 2000 | 84 | 336.7 | 52.4 | 480.2 | 34.9 | 428.3 | 23.3 | 417.6 | 15.9 | 350.2 |

| 1500 | 67.5 | 429.8 | 43.2 | 550.1 | 27.7 | 529.1 | 18.5 | 471.1 | 12.7 | 404.3 | |

| 1000 | 50.5 | 482.3 | 31.4 | 599.7 | 20 | 573 | 13.4 | 511.9 | 9 | 429.8 | |

| 750 | 40.8 | 519.5 | 25.2 | 641.8 | 15.7 | 599.7 | 10.4 | 529.7 | 6.95 | 442.5 | |

| SJV-240 | 2000 | 111 | 475.8 | 71.5 | 643.7 | 52.4 | 695.2 | 37.7 | 652.3 | 28.9 | 643.8 |

| 1500 | 90.5 | 576.2 | 58.5 | 744.9 | 41.9 | 800.3 | 30.2 | 769.1 | 23.4 | 744.9 | |

| 1000 | 68 | 649.4 | 41.9 | 800.3 | 30.2 | 865.2 | 21.7 | 828.9 | 16.4 | 783.1 | |

| 750 | 54.5 | 694 | 33.8 | 860.8 | 23.6 | 901.5 | 17.1 | 871 | 13 | 827.7 | |

| SJV-280 | 2000 | 168 | 837.5 | 107 | 961.4 | 73 | 957 | 47.6 | 870.4 | 39.4 | 890.5 |

| 1500 | 156 | 993.2 | 88 | 1121 | 58.5 | 1117 | 38.5 | 980.5 | 31.4 | 999.6 | |

| 1000 | 115 | 1098 | 64.5 | 1232 | 42.4 | 1215 | 27.5 | 1051 | 22.4 | 1070 | |

| 750 | 94.2 | 1199 | 51 | 1299 | 33.5 | 1280 | 21.7 | 1105 | 17.7 | 1127 | |

Company Informations:

Factory Apprarance Production Workshop

Assembly Workshop Inventory Workshop

SIJIE Team Gearbox Shipment

Why SIJIE cubic spiral bevel gearbox?

1: High-quality, low Backlash, quiet noise, smooth running, high torque bevel gearbox professional manufacturer since 2008.

2: The wide range of bevel gearbox product lines can meet the application needs of customers to the greatest extent.Gearbox housing size is from 065 to 280. Casting iron, stainless steel, and aluminum version gearboxes can be manufactured according to customers’ requirements.

3: Strict quality control has been from the beginning to end at SIJIE. All the cubic bevel gearboxes will be tested in our factory accordingto the more than 30 items checking list before shipping.

4: SIJIE cubic type bevel gearbox has 13 months warranty period, during the warranty period, any problem with “SIJIE” products,after we confirmed, we will guide the customer to fix or ship a new 1 to replace it in 1-3 working days.

5: SIJIE kept a large inventory of cubic spiral bevel gearbox parts to make sure all the standard orders can be shipped in 7 working days.

6: Our Experienced Engineer Team can design the bevel gearbox drawings to fit all your demands in 2 hours. Small-quantity OEM/ODM orders also can be accepted by SIJIE. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Hardness: | Hardened Tooth Surface |

| Step: | Single-Step |

| Gear Ratios: | 1:1, 2:1, 3:1, 4:1, 5:1 |

| Configurations: | 2-Way, 3-Way, 4-Way Shafts |

| Samples: |

US$ 95/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Lubrication Practices for Extending the Lifespan of Agricultural Gearboxes

Proper lubrication is essential for ensuring the longevity and optimal performance of agricultural gearboxes. Here are some essential lubrication practices that can help extend the lifespan of these gearboxes:

- Choose the Right Lubricant: Select a high-quality lubricant specifically designed for gearboxes and agricultural machinery. Consider factors such as viscosity, temperature range, and load-bearing capacity to ensure compatibility with the gearbox’s operating conditions.

- Regular Inspection: Perform regular visual inspections of the gearbox and lubricant to check for signs of contamination, wear, or inadequate lubrication. Address any issues promptly to prevent further damage.

- Cleanliness: Maintain a clean environment around the gearbox to minimize the risk of dirt, debris, and moisture entering the gearbox housing. Contaminants can compromise the lubricant’s effectiveness and accelerate wear.

- Lubricant Level: Monitor and maintain the proper lubricant level in the gearbox. Insufficient lubrication can lead to increased friction and heat, causing premature wear and potential damage to gears and bearings.

- Replace Lubricant: Follow the manufacturer’s recommendations for lubricant change intervals. Over time, lubricants can degrade, lose their properties, and become contaminated. Regularly replacing the lubricant helps ensure optimal performance.

- Use Lubrication Schedule: Create a lubrication schedule based on the gearbox’s usage and operating conditions. Stick to the recommended intervals for applying or changing lubricant to prevent under-lubrication or over-lubrication.

- Appropriate Lubrication Method: Follow the manufacturer’s guidelines for the correct lubrication method, whether it’s through oil bath, grease, or automatic lubrication systems. Proper application ensures even distribution of lubricant across gear surfaces.

- Temperature Considerations: Be aware of temperature variations in your operating environment. Extreme temperatures can affect lubricant viscosity and performance. Choose a lubricant that can handle the temperature range of your equipment.

- Expert Advice: Consult the gearbox manufacturer or a lubrication specialist to determine the best lubrication practices for your specific agricultural gearbox model and application.

By adhering to these lubrication practices, farmers can maximize the lifespan of their agricultural gearboxes, minimize downtime, and ensure efficient and reliable operation of their equipment.

Types of Farming Equipment Incorporating Agricultural Gearboxes

Agricultural gearboxes play a vital role in various farming equipment, enhancing their efficiency and enabling them to perform essential tasks. Here are some types of farming equipment that commonly incorporate agricultural gearboxes:

- Tractors: Agricultural gearboxes are integral components of tractors, contributing to power transmission from the engine to various attachments such as plows, harrows, and mowers.

- Harvesters: Harvesters, used to gather crops like grains, fruits, and vegetables, utilize gearboxes to drive conveyor systems and separators, ensuring smooth and efficient harvesting operations.

- Planters and Seeders: Planters and seeders rely on gearboxes to precisely distribute seeds and fertilizers while maintaining the desired planting depth.

- Sprayers: Agricultural gearboxes are used in sprayers to drive pumps that distribute pesticides, herbicides, and fertilizers over fields.

- Hay Balers: Gearboxes are essential in hay balers for compacting and forming bales of hay, enabling easy storage and transportation.

- Manure Spreaders: Manure spreaders incorporate gearboxes to distribute and spread fertilizers and compost evenly across fields.

- Grain Augers: Grain augers, used for loading and unloading grains, feature gearboxes to drive the rotating screw mechanism that lifts and transfers grains.

- Cultivators: Cultivators use gearboxes to drive rotating tines or blades that loosen and prepare the soil for planting.

- Rotary Cutters: Rotary cutters, often attached to tractors, utilize gearboxes to power the spinning blades used for cutting tall grass, weeds, and brush.

- Threshers: Threshers, employed for separating grains from their husks or stalks, incorporate gearboxes to drive the threshing mechanisms.

These examples demonstrate the diverse applications of agricultural gearboxes across a wide range of farming equipment. By providing reliable power transmission and control, agricultural gearboxes contribute significantly to the productivity and efficiency of modern agricultural practices.

Maintenance Requirements for Agricultural Gearboxes

Maintaining agricultural gearboxes is crucial to ensure the smooth and efficient operation of farming equipment. Proper maintenance helps extend the lifespan of gearboxes and prevents costly breakdowns. Here are the key maintenance requirements:

- Regular Inspections: Conduct routine visual inspections to check for signs of wear, damage, leaks, or misalignment. Regularly inspect gear teeth, seals, and bearings for any issues.

- Lubrication: Proper lubrication is essential to minimize friction and wear in gearboxes. Follow the manufacturer’s guidelines for the type of lubricant to use and the recommended intervals for lubrication.

- Lubricant Checks: Monitor the gearbox’s lubricant levels and quality regularly. Replace or replenish lubricants as needed, and ensure that contaminants are kept out of the lubrication system.

- Tightening Bolts and Fasteners: Check and tighten bolts, nuts, and fasteners to prevent loosening due to vibrations during operation. Loose components can lead to misalignment and premature wear.

- Seal Inspection: Examine seals for leaks and proper sealing. Damaged or worn seals should be replaced promptly to prevent lubricant leakage and the ingress of contaminants.

- Cleaning: Keep gearboxes clean by removing dirt, debris, and residue. Regular cleaning prevents abrasive particles from entering the gearbox and causing damage.

- Alignment: Ensure that gearboxes are properly aligned with connected components, such as shafts and couplings. Misalignment can lead to increased wear and reduced efficiency.

- Temperature Monitoring: Monitor the operating temperature of the gearbox. Abnormal temperature increases may indicate issues like overloading or insufficient lubrication.

- Filter Replacement: If the gearbox has a filtration system, regularly replace or clean the filters to prevent contaminants from entering the gearbox.

- Expert Inspection: Periodically have gearboxes inspected by qualified technicians. They can identify potential problems that may not be visible during routine inspections.

Adhering to these maintenance requirements ensures that agricultural gearboxes remain in optimal condition and contribute to the reliability and efficiency of farming equipment. Regular maintenance not only prevents unexpected downtime but also prolongs the service life of the gearboxes, ultimately benefiting the productivity of agricultural operations.

editor by CX 2024-01-02

in Accra Ghana sales price shop near me near me shop factory supplier Helical Hypoid Spiral Bevel Gearbox with Input Flange manufacturer best Cost Custom Cheap wholesaler

The team is targeted on producing all variety of standard roller chains and sprockets, gears & gearboxes, this sort of as conveyor chain & sprockets , stainless metal chain, agricultural chain and has not just sold its merchandise all above china, but also bought a lot more than sixty five% items to oversees, including Europe, The united states, South-east Asia, and it also has set up storage logistics in areas like Europe. Trying to keep in brain that excellent provider is the key to cooperating with clients, we strive to meet up with substantial high quality standards, offer competitive costs and make sure prompt shipping and delivery. In the meantime, our merchandise are made according to high top quality requirements, and complying with the intercontinental sophisticated standard standards. Inline Shaft Flange Mounted XGK Series Helical Gear EPTTs

1.Item characteristics

one.one. XGK Sequence Hypoid EPTTl Helical Equipment EPTT

1.two.Larger reduction ratio with challenging surface hypoid EPTTl and helical EPTT EPTT

1.3. Big output torque,higher EPTT effectiveness, vitality-conserving

one.four.Fine casting of EPTT alloy,ligEPTT bodyweight,rust-proof

one.5. A variety of mounting positions,extensive application,effortless utilizing

one.six. Mounting dimension is interchangeable with RV series worm EPTT

1.seven. Multi-levels EPTT EPTT.It is divided into two phase EPTT (one particular hypoid EPTTl EPTT and one particular helical EPTT) and three phase EPTT(a single hypoid EPTTl EPTT and two helical EPTTs)

two. EPTT parameters

| Variety | XKG hypoid EPTTl helical EPTT EPTT |

| Model | XGK63,XGK75 |

| Ratio | 5-a hundred and fifty |

| Color | blue or OEM colors |

| EPTT | ADC12 EPTT, 20CrMnti |

| Input | connected with stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd flange motor and servo motor with numerous specification |

| Output | hollow shaft and soild shaft |

| EPTT | C ampU |

| Seal | NAK, SKF |

| Enter EPTT | .12KW-4KW |

| Max outpu ttorque | XGK63(250Nm),XGK75(400Nm) |

| Usages | In EPTT EPTT: Foodstuff stuff,Ceramics,chemical, aswell as EPTT, printing, dyeing,woodworking, EPTT and plastics.. |

| Mounting variety | Foot mounted,flange mounted |

| Lubricant | VG220 |

three.Programs

HangEPTT XG EPTT EPTT EPTT are extensively used in :

Ceramic Industry

Glass Industry

Foodstuff Business

EPTTlurgy Industry

Beer amp Consume Sector

EPTT and dyeing Business

Textile Sector

Warehouse Logoistics Sector

EPTT doing work EPTTry

environmental safety gear Industry

Leather Sector

Pharmacy Business

four.Our Services

four.one.We supply 12 months Warranty.

four.2. We have 1000’s of EPTT EPTTs. From Enter EPTT .06KW to 200KW, Ratio one.three-289.seventy four, Output speed -1095rpm and Output torque 1.four-62800Nm. They can fulfill your all diverse needs for various EPTT.

4.three. We supply E-catalog or Paper catalog,so you can decide on the product easily according to your specifications

4.four.You are welcome to pay a visit to our factory to verify our goods,we can aid you to book the lodge or ticket

five.Organization Data

five.1.Our Company:

The Predecessor for ZheJiang EPTT Push CO.,Ltd (at first referred to as HangEPTT XiHu (West Lake) Dis.ngguang EPTT EPTTry CO.,Ltd) Condition-owned armed forces mould EPTTrpriese which estabEPTTd in 1965.

EPTT is found in HangEPTT,EPTT and the manufacturing facility covers an location of about 25000 square meters.

Production Capability:more than 50 % a million sets of speed EPTT for each calendar year.

5.2.Our People:

The organization has a sturdy technical power. It has far more than four hundred employees at present, incXiHu (West Lake) Dis.Hu (West Lake) Dis. far more than forty engineering specialists and ten professionals and senior engineers enEPTTing EPTT allowances of the Condition Council.

5.three. Our Certificates:

Handed quot ISO 9001 International EPTT Technique Certification quot, quotInternational EPTT Credit history AAA Ceritifacte quot , quot Swiss SGS Certification quot, Legendary Model in EPTT EPTT Market quot, quotFamous Manufacturer of ZheJiang Province quot, quotNon-community Scientific and Technological EPTTrprise in ZheJiang Province quot, quotNational High and EPTT-tech EPTTrprise quot, quotTOP 50 in EPTT Equipment Market quot quot2011 HangEPTT Engineering and Technological R ampD CEPTTr quot and so on.

6. FAQ

Q:Are you a trading firm or maker?

A: The predecessor of HangEPTT XG-EPTT EPTTry Co., Ltd is Condition-owned XiHu (West Lake) Dis.ngguanggong Mildew Manufacturing facility, a condition-owned military EPTT EPTTrprise estabEPTTd in 1965. It completed reform in 2002. Given that reform, EPTT has deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ed speedily. It took the direct in passing ISO9001 Intercontinental EPTT Program Certification and Global EPTT Credit AAA Certificate in 2004, and Swiss SGS Certificate in 2009. It has won these kinds of titles as quotIconic Model in EPTT EPTT Business quot, quotFamous Model of ZheJiang Province quot, quotNon-community Scientific and Technological EPTTrprise in ZheJiang Province quot, quotNational Higher and EPTT-tech EPTTrprise quot, and quotTope fifty in EPTT Equipment Industry quot successively

Q:Exactly where do you base?

A: We are in HangEPTT,ZheJiang ,EPTT. We have two factories,EPTT factory is in XiHu (West Lake) Dis.hu (West Lake) Dis. district,HangEPTT,EPTT and the old one is in CHangEPTT District,HangEPTT,EPTT.

Q:What sorts of EPTT can you produce for us?

A:Primary products of our firm: JWB-X series mechanical constantly variable EPTT, RV series worm EPTT EPTT, B/JXJ cycloidal pin EPTT speed EPTT, NCJ series EPTT EPTT, and R, S, K, and F collection helical-tooth EPTT, a lot more than a single hundred types and countless numbers of specs.

Q:What are the application of the EPTT?

A:EPTT are commonly utilized in ceramic, EPTT, food, metallurgy, beer amp consume, printing and dyeing, textile, petrochemical engineering, warehouse EPTT, wooden-working EPTT, environmental security gear, printing and EPTT, pharmacy, and leather. EPTT are bought in some nations around the world and areas, this sort of as Europe, The united states, and SouthEPTT Asia, and it possesses dozens of distributors and after-sale services agents.

Q:What is the content you use?

A: EPTT case ( For the RV series worm EPTT,model RV030-one zero five)

Solid iron(For the RV series worm EPTT, design RV110-150, For the NCJ /F/R/S/K series helical EPTT EPTT)

in Campo Grande Brazil sales price shop near me near me shop factory supplier Spiral Bevel Helical Gearbox Box 90 Degree High-Quality Transmission Right Angle Speed Reducer Alloy Steel Stainless Induction Straight Spiral Bevel Gearboxes manufacturer best Cost Custom Cheap wholesaler

Every approach, each part, each purpose in EPG is demanded to be carried out one particular action pursuing another, cautiously and cautiously, from content assortment, reformation to manufacturing accessories, from parts heat remedy to automatic assembly, from high quality management to item inspection and tests and from order working to soon after product sales provider. “We are often serving our customers with our best items.” Full use has been manufactured of all types of innovative tactics and technologies to get to excelsior manufacturing.

Spiral EPTTl Helical EPTT Box 90 Degree Large-EPTT EPTT RigEPTT Angle Velocity EPTT Alloy Steel Stainless Induction StraigEPTT Spiral EPTTl EPTTes

China manufacturer & factory supplier for T in Jos Nigeria series spiral bevel gear 90 degree 1 to 1 ratio gearbox worm gear speed reducer tiller gearbox With high quality best price & service

We search forward to the possibility to provide you and hope to add you to our expanding family members of satisfied buyers.EPG has been successfully qualified by ISO9002 Quality Administration System, ISO9001 Top quality Management System, API certificate, ISO/TS16949:2002 and ISO10012 measurement management system.

Overview

Swift Particulars

- Applicable Industries:

-

Creating Materials Retailers

- Gearing Arrangement:

-

Bevel / Miter

- Output Torque:

-

Up to 3378Nm

- Enter Speed:

-

750-1500rpm

- Output Pace:

-

3~1450r/min

- Place of Origin:Zhejiang, China

- Model Identify:

-

OEM

- Certification:

-

ISO9001-2008

The PTO shaft included with all Victory Tractor mowers has a longer extension than the normal PTO Shaft. The additional length is essential because of the considerably achieving motion of the mowers to the appropriate of the tractor.

- Mount Placement:

-

Foot Mounted

- Bearing:

-

C&U,ZWZ,SKF,LYC,HRB

- gear precision quality:

-

din four

Offer Ability

- Offer Potential:

- 1000 Device/Units per Month

Packaging & Shipping and delivery

- Packaging Particulars

- Regular wood circumstance

- Port

- Ningbo Port, Shanghai Port

It is our goal to source a huge assortment of good quality goods at affordable costs, offer the ideal services for clients happy and lead to our continued advancement.

On the internet Customization

T collection spiral bevel equipment 90 diploma 1 to 1 ratio gearbox worm equipment pace reducer tiller gearbox

Merchandise Description

Gain:

-Self-locking capacity

-Can be driven directly by motor or other power or guide

-Can be tailored in accordance user’s need

-Compact configuration, little size, lightweight

-Hassle-free installation, adaptable operation

-Substantial dependability and security

-Long services daily life

-A lot more relationship sort and so forth.

Screw jak is utilized to all fields for lifting or pulling, these kinds of as Aircraft upkeep system, Solar plate, machinery, metallurgy, water conservancy, health-related remedy, chemical market, tradition and hygienist and so on.

Specifications:

one.Tseries sprial bevel equipment reducer with various varieties are standardized

two.all ratiThe result is a drive resolution that reflects our bundled useful understanding, which is perfectly adapted to your requirements as a customer. Nevertheless, our task does not stop with delivery and installation. We are often there to offer you with tips and help through the whole lifecycle of our goods.o of 1:1,1.5:12:12.5:thirteen:14:1and 5:1 are true kinds,

3.regular effectiveness is 98%.

|

Merchandise Name |

T sequence Spiral Bevel Gearbox |

|

model no. |

T2, T4, T6, T7, T8, T10, T12, T16, T20, T25 |

|

Ratio |

1:1, 1.5:1, 2:1, 2.5:1,3:1,4:1,5:1 |

|

gear Material |

large grade synthetic diamond 50CrMnT |

|

Equipment Processing |

Grinding finish by HOFLER Grinding Machines, Precision quality : DIN 4 |

|

spindle |

higher purity steel alloy 40Cr piece |

|

Sounds Examination |

Bellow 65dB |

|

Guarantee |

1 12 months |

Business Details

Certifications

Our Providers

Packaging & Transport

Expo& Clients

FAQ

: Are you buying and selling firm or producer ?

A: We are manufacturing facility.

Q: How extended is your supply time?

A: Generally it is 5-10 days if the products are in inventory. or it is 15-20 times if the merchandise are not in stock, it is in accordance to quantity.

Q: Do you give samples ? is it totally free or extra ?

A: Indeed, we could supply the sample for totally free cost but do not pay out the expense of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, thirty% T/T in advance ,equilibrium ahead of shippment.

If you have an additional question, pls really feel free to get in touch with us as under:

Connected Items

custom high quality bevel gearbox spiral Mini bevel gearbox 90 degree vertical to horizontal gearbox 220v gear motor 24 volt dc gear motor

In 2008, it was awarded with “National Export Commodity Inspection-cost-free Organization”. a specialized supplier of a complete variety of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers. Furthermore, WE CAN Produce Tailored VARIATORS, GEARED MOTORS, Electrical MOTORS AND OTHER HYDRAULIC Products In accordance TO CUSTOMERS’ DRAWINGS.

Overview

Rapid Particulars

- Relevant Industries:

-

Accommodations, Garment Outlets, Building Substance Retailers, Producing Plant, Equipment Fix Outlets, Meals amp Beverage Manufacturing unit, Farms, Cafe, Home Use, Retail, Foodstuff Shop, Printing Stores, Development operates nbsp, Vitality amp Mining, Foods amp Beverage Shops, Advertising Organization

- Spot of Origin:Zhejiang, China

- Manufacturer Title:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

ten~62800N.m

- Enter Pace:

-

1450/960rpm

- Output Velocity:

-

fourteen-280rpm

- Ratio:

-

5.36~197.37

- Certification:

-

ISO9001-2008

- Mount Place:

-

Foot Mounted

- Bearing:

-

C ampU,LYC, HRB,ZWZ,SKF,NSK

Packaging Supply

- Promoting Models:

- Single merchandise

- Single bundle dimensions: nbsp

- 35X35X50 cm

- Single gross fat:

- 47.000 kg

- Package deal Sort:

- Wood packing containers , Cantons packed in one pallet

-

Direct Time

: -

Amount(Models) 1 – 1 >1 Est. Time(days) seven To be negotiated

On the internet Customization

Product Description

nbsp

K series helical bevel gearbox electric motor reduction gearbox is a single variety of Helical Bevel kind gearbox , High-stainless solid iron circumstance . ,it is developed based on modularization , which provide several variation sorts of combinations ,mounting types ,and structure designs .The element classification of ratio can meet up with different of functioning problem .High Transmission performance ,Lower energy use, outstanding efficiency . The hard tooth area gear use the higher good quality alloy steel , the process of carburizing and quenching, grinding ,which give it follow figures : Steady transmission , low sound and temperature ,higher loading ,prolonged working daily life. which widely use for market gear of metallurgy ,Developing Substance , Chemical , Mining , Oil, Transportation , Papermaking , Sugar producing , engineering Devices ,etc

one) Output pace: .6~one,028r/min

two) Output torque: up to 21700N.m

three) Motor electrical power: .twelve~200kW

four) Mounted kind: foot-mounted and flange-mounted mounting

|

Pro nbsp duct Name |

K series helical bevel gearbox electric powered motor reduction gearbox |

|

Gear Materials |

20CrMnTi nbsp |

|

Situation Substance |

HT250 |

|

Shaft Substance nbsp |

20CrMnTi |

|

Equipment Processing |

Grinding complete by HOFLER Grinding Machines |

|

Coloration nbsp |

Personalized |

|

Noise Take a look at |

sixty five~70dB |

|

Effectiveness |

ninety four%~ninety eight% (is dependent on the transmission phase) nbsp |

|

Lubricating oil |

Shell Omala synthetic oil or mineral oil , or related model nbsp |

|

Heat therapy |

tempering, cementiting, quenching,and so forth. |

|

Model of bearings |

C ampU bearing, ZWZ,LYC, HRB, SKF,NSK and so on |

|

Manufacturer of oil seal |

NAK or other model |

|

Temp. increase (MAX) |

40 deg |

|

Temp. increase (Oil)(MAX) |

fifty deg |

|

Vibration |

ep20 microm |

nbsp

nbsp

nbsp

nbsp

nbsp

nbsp

Organization Information

About us

Set up in 1985, SANLIAN nbspTRANSMISSION nbspMACHINERY nbspCO., nbspLTD is a higher and new technology organization participating nbspin analysis, nbspdevelop nbspand manufacture nbspfor reducer amp pace variator, one of the director member of China Reducer Affiliation of China Standard Equipment.

It nbspcovers a lot more than nbsp40,000 square meters, has far more than 400 employees , 20% of whom are specialists, outfitted with more than three hundred sets the most advanced precise numerical control nbspequipment, which includes German HOFLER forming nbspgear grinding machine to enhance top quality.

set up much more than 30 nationwide income branches to serve our customers in time and completely.

Our merchandise also nbspexported to much more than 30 international locations nbspmain nbspin Europe, Asia nbsp nbspAmerica, nbspand Africa, with substantial track record.

nbsp

At any time-electrical power

nbsp

Packing Specifics: Standard carton/Pallet/Regular wood scenario

Shipping and delivery Details : 7-twenty operating times upon payment

nbsp

nbsp

Related Solution

Make contact with us

FAQ

one.Payment Time period: TT, L/C

two.Delivery time: about nbsp 30 times from receive payment. nbsp

three.We accept customized goods as per your specific necessity.

four.Recommendations for the Variety:Normally we can select 1 equipment which is suitable for you with some informations from you,these kinds of as ratio/motor speed/mounting dimension/ out torque etc. nbsp

5.If the minimum get amount is in excessive of $ten thousand, there are preferential.

Q1: What info ought to I inform you to validate the product?

A:Model/Dimension, Transmission Ratio, Shaft directions amp Buy quantity.

Q2: What can i do if I never know which one particular I need to have?

A:Dont worry, Send out as significantly information as you can, our crew will help you discover the right 1 you are hunting for.

Q3: What is your item guarantee interval?

A:We provide one year guarantee considering that the vessel departure day still left China.

nbsp

Q4: Are you trading firm or maker ?

A: We are factory.

nbsp

Q5: How long is your shipping and delivery time?

A: Typically it is five-10 days if the products are in stock. or it is 15-20 days if the products are not in stock, it is in accordance to amount.

nbsp

Q6: Do you supply samples ? is it totally free or added ?

A: Sure, we could supply the sample for totally free demand but do not pay out the cost of freight.

nbsp

Q7: What is your conditions of payment ?

A: Payment lt=1000USD, a hundred% in advance. Payment gt=1000USD, 30% T/T in progress ,stability before shippment.

nbsp

If you have another question, pls really feel cost-free to get in touch with us as underneath: