Product Description

Product Advantages

|

F Series Gearbox Reducer |

|

|

Product name |

F series of the gearbox hollow shaft model F107 oil seal transmission gearbox reducer reduction |

|

Warranty |

1 years |

|

Applicable Industries |

Manufacturing Plant |

|

Weight (KG) |

50KG |

|

Customized support |

OEM |

|

Gearing Arrangement |

Helical |

|

Output Torque |

1.8-2430N.M |

|

Input Speed |

1440, 2800,960,750 |

|

Output Speed |

0.5 to 200 |

|

Place of Origin |

China |

|

Product name |

F Series Parallel Shaft Gearbox Reducer |

|

Application |

Hardened Tooth Surface |

|

Installation |

Horizontal Type |

|

Layout |

Coaxial |

|

Gear Shape |

Helical |

|

Production Capacity |

800-1500PCS /Month |

|

Type |

Gear Reduction Motor |

|

Color |

Blue,Sliver or Customized |

|

Packing |

Wooden Box |

Six advantages

Our Advantages

–Modular design, wide transmission ratio coverage, fine and reasonable distribution; Force reducer

–There are 11 types of frame specifications from F.27-F.157, and the transmission power range is 0.12KW-200KW;

–The shape design is suitable for omnidirectional universal installation configuration;

–The transmission is relatively accurate, covering the range of 3.77-281.71, and can be selected as required;

–The gear is grinded by high-precision gear grinding machine, with balanced transmission, low noise, and interstage efficiency of 98%;

–The transmission ratio of the F.R.reducer is extended to 31431, which is specially designed for special low-speed occasions

Editing and broadcasting of main materials

–Box: cast iron;

–Gear: low carbon alloy steel, carbonitriding treatment (after fine grinding, keep the tooth surface hardness of 60HRC, hard layer thickness>0.5mm);

–Flat key: 45 steel, with surface hardness above 45HRC.

Surface painting:

–Cast iron: sprayed with RAL7031 grey blue paint.

Parameter editing broadcast

Power: 0.18KW~200KW

Torque: 3N · m ~ 22500N · m

F series parallel shaft reducer

F series parallel shaft reducer

Output speed: 0.06~374r/minF series parallel shaft reducer [1]

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Motorcycle, Machinery, Agricultural machine |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Layout: | Expansion, Parallel |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | |

|---|

Impact of Gear Ratios on Machinery Performance in Agricultural Gearboxes

The gear ratio in agricultural gearboxes plays a crucial role in determining the performance of machinery. It directly affects the relationship between the input and output speeds and torques. Here’s how gear ratios influence machinery performance:

- Speed and Torque Conversion: Gear ratios allow for the conversion of speed and torque between the input and output shafts. Higher gear ratios can reduce output speed while increasing output torque, making it suitable for tasks requiring high power.

- Power and Efficiency: Gear ratios affect the efficiency of power transmission. While reducing the speed through higher gear ratios can increase torque, it’s essential to strike a balance to maintain efficiency. Lower efficiency can lead to energy loss and increased heat generation.

- Task Adaptability: Different agricultural tasks require varying levels of torque and speed. Gear ratios enable machinery to be adaptable to different tasks by providing the necessary torque for heavy-duty activities like plowing or tilling and higher speeds for tasks like transport.

- Optimal Performance: Selecting the appropriate gear ratio ensures that machinery operates within its optimal performance range. It prevents overloading the engine or the gearbox, contributing to smoother operation and reduced wear and tear.

- Productivity and Fuel Efficiency: Proper gear ratios can enhance the overall productivity of agricultural machinery. By optimizing torque and speed, tasks can be completed efficiently, reducing the time and fuel consumption required for operations.

- Consideration of Terrain: Different terrains and field conditions require adjustments in gear ratios. Steep slopes or heavy soil may necessitate lower gear ratios for increased torque, while flat terrain could benefit from higher ratios for faster operation.

- Impact on Components: Gear ratios can influence the load distribution on gearbox components. Higher gear ratios might subject components to increased forces and stresses, potentially affecting their lifespan.

- Operator Comfort: Proper gear ratios contribute to operator comfort by providing the necessary power for smooth operation without straining the machinery. This can lead to reduced operator fatigue and improved safety.

- Customization: Some modern agricultural equipment offers adjustable or variable gear ratios, allowing operators to fine-tune machinery performance based on specific tasks and conditions.

Choosing the right gear ratio for agricultural gearboxes involves considering factors such as the intended task, soil conditions, and equipment specifications. It’s essential to strike a balance between torque and speed to achieve optimal machinery performance and maximize productivity.

Handling Varying Torque Demands with Agricultural Gearboxes

Agricultural gearboxes are designed to handle the varying torque demands associated with different tasks in farming operations. The torque requirements can vary based on factors such as the type of task, the soil conditions, the terrain, and the machinery’s speed. Agricultural gearboxes are equipped with features that allow them to adapt to these varying torque demands:

- Gear Ratio Selection: Agricultural gearboxes often come with multiple gear ratios, allowing operators to select the appropriate ratio for the task at hand. Lower gear ratios provide higher torque for tasks that require more force, such as plowing or tilling, while higher gear ratios offer higher speeds for tasks like mowing or transporting.

- Torque Multiplier: Some agricultural gearboxes are designed with torque multipliers that enhance the torque output from the engine to the wheels or implement. These multipliers are engaged when higher torque is needed, helping the machinery handle heavy loads or challenging terrain.

- Adjustable Speeds: Many agricultural gearboxes allow operators to adjust the speed of the machinery to match the torque requirements of the task. This flexibility is essential for tasks that involve both high-torque, low-speed operations and high-speed operations with lower torque needs.

- Power Take-Off (PTO) Options: Agricultural gearboxes often feature power take-off mechanisms that enable the transfer of power from the engine to attached implements. These mechanisms can be designed to provide varying torque outputs to suit different implements, such as rotary tillers, balers, or pumps.

The ability of agricultural gearboxes to handle varying torque demands is crucial for ensuring efficient and effective farming operations. By offering adjustable gear ratios, torque multipliers, and adaptable speeds, these gearboxes empower farmers to optimize their machinery’s performance based on the specific requirements of each task.

Maintenance Requirements for Agricultural Gearboxes

Maintaining agricultural gearboxes is crucial to ensure the smooth and efficient operation of farming equipment. Proper maintenance helps extend the lifespan of gearboxes and prevents costly breakdowns. Here are the key maintenance requirements:

- Regular Inspections: Conduct routine visual inspections to check for signs of wear, damage, leaks, or misalignment. Regularly inspect gear teeth, seals, and bearings for any issues.

- Lubrication: Proper lubrication is essential to minimize friction and wear in gearboxes. Follow the manufacturer’s guidelines for the type of lubricant to use and the recommended intervals for lubrication.

- Lubricant Checks: Monitor the gearbox’s lubricant levels and quality regularly. Replace or replenish lubricants as needed, and ensure that contaminants are kept out of the lubrication system.

- Tightening Bolts and Fasteners: Check and tighten bolts, nuts, and fasteners to prevent loosening due to vibrations during operation. Loose components can lead to misalignment and premature wear.

- Seal Inspection: Examine seals for leaks and proper sealing. Damaged or worn seals should be replaced promptly to prevent lubricant leakage and the ingress of contaminants.

- Cleaning: Keep gearboxes clean by removing dirt, debris, and residue. Regular cleaning prevents abrasive particles from entering the gearbox and causing damage.

- Alignment: Ensure that gearboxes are properly aligned with connected components, such as shafts and couplings. Misalignment can lead to increased wear and reduced efficiency.

- Temperature Monitoring: Monitor the operating temperature of the gearbox. Abnormal temperature increases may indicate issues like overloading or insufficient lubrication.

- Filter Replacement: If the gearbox has a filtration system, regularly replace or clean the filters to prevent contaminants from entering the gearbox.

- Expert Inspection: Periodically have gearboxes inspected by qualified technicians. They can identify potential problems that may not be visible during routine inspections.

Adhering to these maintenance requirements ensures that agricultural gearboxes remain in optimal condition and contribute to the reliability and efficiency of farming equipment. Regular maintenance not only prevents unexpected downtime but also prolongs the service life of the gearboxes, ultimately benefiting the productivity of agricultural operations.

editor by CX 2024-01-16

China manufacturer G3 series three phase motor reducers Helical Gearbox with IEC Input Reducer Power Transmission Equipment planetary gearbox

Relevant Industries: Accommodations, Garment Shops, Manufacturing Plant, Equipment Restore Stores, Foodstuff & Beverage Manufacturing unit, Home Use, Printing Stores, Design works , Advertising Firm

Fat (KG): 6

Gearing Arrangement: Helical

Output Torque: 3.2N.M~~764N.M

Enter Speed: 1400rpm

Output Pace: 280~~7rpm

Merchandise identify: Gear Box

Color: Blue

Ratio: 5 200

Certification: ISO 9001:2008

Gearbox model: Specific Utilized

set up: foot mounted/flange mounted

Packaging Details: 1 pc / carton,several cartons / picket pallet10000 Piece/Items for each Thirty day period in accordance to the genuine detail details of gearbox

Goods Description Advised Merchandise Personal computer front helical gear Higheroutput torque We produce speed reducers in stringent accordance with ISO9001 standard to offer our clients with substantial good quality gearboxes at competitive charges. Our gearboxes are outfitted with add-ons from global renowned makes, these kinds of as oil seal from CZPT brand name,lubricant from Shell brand name, and bearing from CZPT model. The housing and equipment are made in our organization underneath stringent high quality handle. All our products are offered in large shares, and we can also offer you with tailored reducer answers, pleasefeel assured to make contact with us.

| powerkw | outputshaft | G3lS | UDL | primary outline and dimension-mount | ||||||||||

| A | B | F | I | J | O | |||||||||

| 0.eighteen | Ø18 | 5,10,fifteen,twenty five | 1.6~8.two | 459.5 | 120 | 120 | 11 | 16.5 | 4 | |||||

| Ø22 | 30,forty,50,60,80,100 | 1.4~7. | 485.five | 120 | 220 | 11 | 19 | 4 | ||||||

| Ø28 | 100,one hundred twenty,a hundred and sixty,200 | 1.4~7. | 499 | 120 | 220 | 11 | 23.5 | 4 | ||||||

| 0.37 | Ø22 | 5,10,fifteen,25 | 1.4~7. | 494 | 141 | 220 | 11 | 19 | 4 | |||||

| Ø28 | 30,forty,50,sixty,eighty,one hundred | 1.4~7. | 510.five | 141 | 220 | 11 | 23.5 | 4 | ||||||

| Ø32 | 100,one hundred twenty,160,two hundred | 1.4~7. | 583.5 | 141 | 220 | 13 | 28.five | 4 | ||||||

| 0.75 | Ø28 | 5,ten,15,25 | 1.4~7. | 649.5 | 160 | 220 | 11 | 23.5 | 4 | |||||

| Ø32 | 30,forty,50,sixty,80,100 | 1.4~7. | 678.5 | 160 | 220 | 13 | 28.5 | 4 | ||||||

Choosing a Gearbox For Your Application

The gearbox is an essential part of bicycles. It is used for several purposes, including speed and force. A gearbox is used to achieve one or both of these goals, but there is always a trade-off. Increasing speed increases wheel speed and forces on the wheels. Similarly, increasing pedal force increases the force on the wheels. This makes it easier for cyclists to accelerate their bicycles. However, this compromise makes the gearbox less efficient than an ideal one.

Dimensions

Gearboxes come in different sizes, so the size of your unit depends on the number of stages. Using a chart to determine how many stages are required will help you determine the dimensions of your unit. The ratios of individual stages are normally greater at the top and get smaller as you get closer to the last reduction. This information is important when choosing the right gearbox for your application. However, the dimensions of your gearbox do not have to be exact. Some manufacturers have guides that outline the required dimensions.

The service factor of a gearbox is a combination of the required reliability, the actual service condition, and the load that the gearbox will endure. It can range from 1.0 to 1.4. If the service factor of a gearbox is 1.0, it means that the unit has just enough capacity to meet your needs, but any extra requirements could cause the unit to fail or overheat. However, service factors of 1.4 are generally sufficient for most industrial applications, since they indicate that a gearbox can withstand 1.4 times its application requirement.

Different sizes also have different shapes. Some types are concentric, while others are parallel or at a right angle. The fourth type of gearbox is called shaft mount and is used when mounting the gearbox by foot is impossible. We will discuss the different mounting positions later. In the meantime, keep these dimensions in mind when choosing a gearbox for your application. If you have space constraints, a concentric gearbox is usually your best option.

Construction

The design and construction of a gearbox entails the integration of various components into a single structure. The components of a gearbox must have sufficient rigidity and adequate vibration damping properties. The design guidelines note the approximate values for the components and recommend the production method. Empirical formulas were used to determine the dimensions of the various components. It was found that these methods can simplify the design process. These methods are also used to calculate the angular and axial displacements of the components of the gearbox.

In this project, we used a 3D modeling software called SOLIDWORKS to create a 3-D model of a gear reducer. We used this software to simulate the structure of the gearbox, and it has powerful design automation tools. Although the gear reducer and housing are separate parts, we model them as a single body. To save time, we also removed the auxiliary elements, such as oil inlets and oil level indicators, from the 3D model.

Our method is based on parameter-optimized deep neural networks (DBNs). This model has both supervised and unsupervised learning capabilities, allowing it to be self-adaptive. This method is superior to traditional methods, which have poor self-adaptive feature extraction and shallow network generalization. Our algorithm is able to recognize faults in different states of the gearbox using its vibration signal. We have tested our model on two gearboxes.

With the help of advanced material science technologies, we can now manufacture the housing for the gearbox using high-quality steel and aluminium alloys. In addition, advanced telematics systems have increased the response time of manufacturers. These technologies are expected to create tremendous opportunities in the coming years and fuel the growth of the gearbox housing market. There are many different ways to construct a gearbox, and these techniques are highly customizable. In this study, we will consider the design and construction of various gearbox types, as well as their components.

Working

A gearbox is a mechanical device that transmits power from one gear to another. The different types of gears are called planetary gears and are used in a variety of applications. Depending on the type of gearbox, it may be concentric, parallel, or at a right angle. The fourth type of gearbox is a shaft mount. The shaft mount type is used in applications that cannot be mounted by foot. The various mounting positions will be discussed later.

Many design guidelines recommend a service factor of 1.0, which needs to be adjusted based on actual service conditions. This factor is the combined measure of external load, required reliability, and overall gearbox life. In general, published service factors are the minimum requirements for a particular application, but a higher value is necessary for severe loading. This calculation is also recommended for high-speed gearboxes. However, the service factor should not be a sole determining factor in the selection process.

The second gear of a pair of gears has more teeth than the first gear. It also turns slower, but with greater torque. The second gear always turns in the opposite direction. The animation demonstrates this change in direction. A gearbox can also have more than one pair of gears, and a first gear may be used for the reverse. When a gear is shifted from one position to another, the second gear is engaged and the first gear is engaged again.

Another term used to describe a gearbox is “gear box.” This term is an interchangeable term for different mechanical units containing gears. Gearboxes are commonly used to alter speed and torque in various applications. Hence, understanding the gearbox and its parts is essential to maintaining your car’s performance. If you want to extend the life of your vehicle, be sure to check the gearbox’s efficiency. The better its functioning, the less likely it is to fail.

Advantages

Automatic transmission boxes are almost identical to mechanical transmission boxes, but they also have an electronic component that determines the comfort of the driver. Automatic transmission boxes use special blocks to manage shifts effectively and take into account information from other systems, as well as the driver’s input. This ensures accuracy and positioning. The following are a few gearbox advantages:

A gearbox creates a small amount of drag when pedaling, but this drag is offset by the increased effort to climb. The external derailleur system is more efficient when adjusted for friction, but it does not create as little drag in dry conditions. The internal gearbox allows engineers to tune the shifting system to minimize braking issues, pedal kickback, and chain growth. As a result, an internal gearbox is a great choice for bikes with high-performance components.

Helical gearboxes offer some advantages, including a low noise level and lower vibration. They are also highly durable and reliable. They can be extended in modular fashion, which makes them more expensive. Gearboxes are best for applications involving heavy loads. Alternatively, you can opt for a gearbox with multiple teeth. A helical gearbox is more durable and robust, but it is also more expensive. However, the benefits far outweigh the disadvantages.

A gearbox with a manual transmission is often more energy-efficient than one with an automatic transmission. Moreover, these cars typically have lower fuel consumption and higher emissions than their automatic counterparts. In addition, the driver does not have to worry about the brakes wearing out quickly. Another advantage of a manual transmission is its affordability. A manual transmission is often available at a lower cost than its automatic counterpart, and repairs and interventions are easier and less costly. And if you have a mechanical problem with the gearbox, you can control the fuel consumption of your vehicle with appropriate driving habits.

Application

While choosing a gearbox for a specific application, the customer should consider the load on the output shaft. High impact loads will wear out gear teeth and shaft bearings, requiring higher service factors. Other factors to consider are the size and style of the output shaft and the environment. Detailed information on these factors will help the customer choose the best gearbox. Several sizing programs are available to determine the most appropriate gearbox for a specific application.

The sizing of a gearbox depends on its input speed, torque, and the motor shaft diameter. The input speed must not exceed the required gearbox’s rating, as high speeds can cause premature seal wear. A low-backlash gearbox may be sufficient for a particular application. Using an output mechanism of the correct size may help increase the input speed. However, this is not recommended for all applications. To choose the right gearbox, check the manufacturer’s warranty and contact customer service representatives.

Different gearboxes have different strengths and weaknesses. A standard gearbox should be durable and flexible, but it must also be able to transfer torque efficiently. There are various types of gears, including open gearing, helical gears, and spur gears. Some of the types of gears can be used to power large industrial machines. For example, the most popular type of gearbox is the planetary drive gearbox. These are used in material handling equipment, conveyor systems, power plants, plastics, and mining. Gearboxes can be used for high-speed applications, such as conveyors, crushers, and moving monorail systems.

Service factors determine the life of a gearbox. Often, manufacturers recommend a service factor of 1.0. However, the actual value may be higher or lower than that. It is often useful to consider the service factor when choosing a gearbox for a particular application. A service factor of 1.4 means that the gearbox can handle 1.4 times the load required. For example, a 1,000-inch-pound gearbox would need a 1,400-inch-pound gearbox. Service factors can be adjusted to suit different applications and conditions.

editor by czh

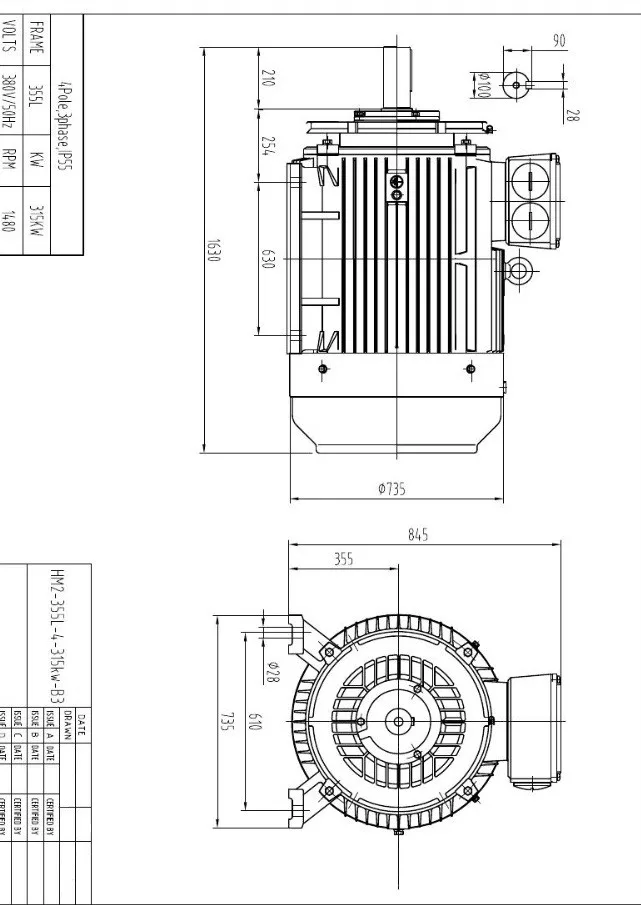

China manufacturer & factory supplier for competitive in Villavicencio Colombia price three phase 4pole ac induction 315kw motor With high quality best price & service

Distributor of precision roller chains made from carbon metal. Obtainable with .two hundred to 1.875 in. roller dia. Flat prime, multi-flex and conveying chains are also presented.Our items are used in many fields.

The PTO shaft is the mechanical unit that transfer the electricity from the tractor to the agricultural apply. The PTO shaft is produced of two joints connected by telescopic tubes: one particular joint connects the outer tube of the PTO shaft with the tractor electricity just take-off , the other joint connects the internal tube of the PTO shaft with the employ. The selection of the EPG Team PTO shafts consists of 9 measurements of different proportions in accordance to the electrical power to be transferred . The sizes of the EPG Group PTO shafts and the power that can be transferred at 540 rpm are : Size 1 up to 16HP Dimensions 2 up to 21HP Size 3 up to thirty HP Size 4 up to 35HP Size 5 up to 47HP Measurement 6 up to 60HP Dimension 7 up to 70HP Dimension 8 up to 90HP SIZE10 up to 110HP

Overview

Rapid Details

- Applicable Industries:

-

Production Plant

- Output Energy:

-

.37-450KW

- Solution Identify:

-

A few-stage asynchronous motor

- Defense course:

-

IP44/IP54/IP55/IP65

- Framework:

-

Asynchonous Motor

- Mounting:

-

B3/B5/B35/B34/B14

- Velocity:

-

2900RPM 1400RPM 960RPM 660RPM

- Poles:

-

2P/4P/6P/8P

- Utilization:

-

Machinery Equipment

- Motor:

-

Y2 Electric powered Motor

Supply Potential

- Provide Potential:

- 3000 Piece/Parts per Thirty day period

Packaging & Supply

- Packaging Specifics

- Plywood box packed

- Port

- Ningbo or Shanghai

-

Lead Time

: -

Quantity(Boxes) one – 9999 >9999 Est. Time(days) 12 To be negotiated

Online Customization

Our items is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The united states, Thailand, Pakistan, Indonesia, much more than 60 international locations and regions.

Frequency:fifty/60Hz

power:.eighteen-450kw

Stage:A few-period

AC Voltage:220/380 and so on

Area of Origin:Zhejiang, China (Mainland)

Performance:IE 2

shade:blue,purple gray and many others.

Device Elements

Y2 collection asynchronous motor .eighteen-450 kw 3 period electric induction motor

one. Great overall performance, protected and reputable operation

two. Low sound, tiny vibration and mild bodyweight

three. Utilized for family equipment, pumps, enthusiast and recording meters

Buying data

1.Make sure you point out the motor kind,rated output,rated voltage,rated frequency,synchronous velocity,Explosion proof Mark,mounting kind,rotation path(look at from the shaft extension aspect)Use of the setting(indoor or outside)If the user havn’t position out the rotation and setting,normailly we think is CW roration and used indoor.

two.when person have specific requirments,For example:Dispose the stator,bearing explosion proof and bearing temperature sensors,room heater,Plateau use,specical frequency,mounting dimensions modify,particular output,the user should ,purchase can be verify right after signing the technological arrangement with engneering division .

3.The catalogue is only fpr reference,and there may be versions.

four.This range of motor can also be created into Variable-Frequency motors,the variety of frequency of which is -100HZ,the output and overall dimensions need to be verify separately.

Pre-Revenue Services

* Inquiry and consulting assistance.

* Sample testing assist.

* View our Manufacturing facility.

After-Sales Service

* Instruction how to instal the device, coaching how to use the equipment.

* Engineers obtainable to service machinery abroad.

Packaging | |

Deliivery | By sea, by air or other people |

Fat | In accordance to item |

Packaging Information | The typical deal is picket box(Measurement: L*W*H). If export to european nations around the world,the picket box will be fumigated.If container is too tigher,we will use pe film for packing or pack it in accordance to customers specific request. |

y collection three period brake asynchronous motor

ninety one.8% Reaction Fee

3 section induction as motor

Industrial Reducers EPG Travel offers two varieties of industrial gearbox, masking common responsibility via to heavier duty and severe obligation applications noticed in some of the world’s most inhospitable mining web sites.91.8% Reaction Price

ninety one.8% Reaction Rate

High permanent magnet brushless dc motor torque equation Cost made in China – replacement parts – in Grande Vitoria Brazil Performance Hot Sale Three Phase Motor Rebar Bending Machine with top quality

We – EPG Group the most significant worm gearbox, couplings and gears factory in China with 5 diverse branches. For more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828 /

Large Overall performance Sizzling Sale 3 Phase Motor Rebar Bending Device

I. Needs and Qualities

GW50 metal bar bending device has robust bending ability, the diameter of wor ept disk is 380mm, It can bend the steel bar with diameter amongst 6-50mm.The bender adopts a closed sound reduction gearbox with ultra-minimal sound. The use of high-overall performance parts tends to make the operation hassle-free, the high quality a lot more stable and the provider existence longer.

GW50 Design Metal Bar Bender is an engineering metal bar bending gear manufactured in accordance to industrial standard JG/T5081-1996. The machine is convenient, dependable and steady.

II. Main Specialized Parameters

| Item | GW50 | |

| Bending Capacity | II Rebar(≤450N) | ≤ø50mm |

| III Rebar(≤650N) | ≤ø40mm | |

| Working Dish Size | ø380mm | |

| Spindle Speed | 5-10rpm | |

| Motor Power | 4KW-50HZ-3P | |

| Weight | 450kg | |

| Dimension | 990×800×860mm | |

| Motor Optional | 380v/220v/415v/440v | |

III. Equipment Structure

GW50 Design Steel Bar Bender mainly is composed of transmission component, rack, bending fixture (accent), and electrical equipment. The theory of primary transmission is that the motor transmits power to degree II straight gear transmission through belt, then stage II gear pair transmits energy to worm by means of driving wheel. The worm transmits energy to worm wheel via spiral, so that the wor ept disk mounted on main shaft receives electricity, which types torque throughout bending process.

Throughout equipment transmission of GW50 Model, trade assembly of 23/33 gears, then wor ept disk can get two speeds: substantial pace and reduced velocity.

Manufacturing unit

Yongyitongfeng Smart Technologies Co., Ltd. is a professional maker of clever metal processing equipment and equipment in China.

•Since the company was established, our products have been exported to more than 40 nations around the world in Southeast Asia, Africa, Europe, The us and Asia Pacific.

•After much more than twenty several years of speedy growth, Yongyitongfeng’s support network covers 40 international locations and regions all around the entire world

•We OEM/ODM for several famous european brands for these sort of device.

Certification

Package

Contract

FAQ

one.How prolonged of the delivery time?

It will take about 3-ten wor ept times to shipping and delivery the Rebar slicing machine, rebar bending device, rebar straightening and slicing machine, etc.

two.what is the warranty time?

12-eighteen months.

three.Do you have agent ?

We are bathroom ept for agent in every single nation, if you have intriguing, really feel cost-free to speak to us

four.How can we use the equipment?

we will send out the english user manual and online video with the equipment, if not enought, we can educate you online.

five.What is the MOQ:

1 set

six.What is the marketing hotline:

0086~13083988828 13858117778271263571

seven.What is the payment term?

30% deposit T/T , balance pay from copy of B/L if CIF or CFR.

fifty% deposit T/T, well balanced pay off when we finish the generation.

eight.How lengthy is the machine’s lifestyle?

Our equipment can use much more than 3-5 a long time(If you typically use the rebar bending machine, you will know the inexpensive machine is 1 year). Our previous buyer mentioned it is extremely sturdy.

nine. can we use alibaba trade assurance?

indeed, welcome to use alibaba trade assurance.

ten. Do you have any low cost?

Sure, we have discount , specially for firm get or Alibaba Trade Assurance get.

eleven.How about the market place ?

It is really well-liked in the industry.

twelve.How can we go to your manufacturing unit?

You can fly from your region to HangZhou international airport by air, then we will prick up you, it takes about 1 hours to our manufacturing facility.

12.How can you supply device to us?

we can deliver device to you by ship, by air and by express. as your like, i will support you to decide on the ideal way.

thirteen. Could you send a lot more specifics of this equipment to us?

Of course, we can send Rebar slicing machine, rebar bending device, rebar straightening and slicing device, and so on. catalogue, tests video clip, put in video clip, far more photographs and the consumer guide to you by e mail.

Primary Solution

/ The use of unique products manufacturer’s (OEM) portion quantities or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating merchandise use and compatibility. Our company and the listed substitute components contained herein are not sponsored, accredited, or created by the OEM. /

Yej factory made in China – replacement parts – in Bhiwandi India Electromagnetic Brake Premium High Efficiency Three Phase Induction AC Electric Asynchronous Motor China Source with top quality

We – EPG Group the largest gearbox & motors , couplings and gears factory in China with 5 various branches. For far more information: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

YEJ series electromagnetic brake motors have the same look, mounting dimension, insulation quality, protection class, way of cooling, composition and set up variety, operate situation, rated voltage and rated frequency as Y series (IP54) motors. This solution is used in numerous machines which call for quick end, correct positioning and back again/forth movements.

Way of Braking: non excitation brake

The rated voltage of the electromagnetic brake is DC99V for power≤3kw, or DC170V for power≥4kw.

ZheJiang Hilair Electromechanical Technologies Co., Ltd, (at first ZHangZhoug Yinda) can date back again to the yr of 1992. Situated in Xihu (West Lake) Dis. Hello-Tech Zone of ZheJiang Province, China, the business will take an spot of sixteen,000 sqm with near two hundred workers. The manufacturing unit is outfitted with complete collection of generation traces and gear. And the yearly output value is all around thirty million US dollars.

Hilair specializes in the design and style and development of AC motors, these kinds of as IE1, IE2, IE3, IE4 collection, cast iron and aluminum housing, AC & DC braked motors, variable frequency motors, grinding device motors, and so forth.

Goods have been exported to all more than the planet with the ideal costs and high top quality.

We always insist on the theory of “individuals oriented, scientific and technological innovation”. We look ept to your extended expression cooperation.

Q1 Are you a company or a ept business?

We are a manufacturer of AC asynchronous motors in China.

Q2 Exactly where is your manufacturing facility?

Xihu (West Lake) Dis., ZheJiang province.

Q3 What is your phrases of payment ?

Payment=1000USD, thirty% T/T in ept , equilibrium ahead of shippment.

This fall What about shipping time?

Normally, 30 days soon after the receipt of payment.

Q5 About shipment?

By sea, By air and By specific delivery.

Q6 About sample?

Obtainable.

The use of original products manufacturer’s (OEM) component quantities or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating solution use and compatibility. Our company and the outlined alternative areas contained herein are not sponsored, accepted, or made by the OEM.

Best China manufacturer & factory Y2 in Abeokuta Nigeria Series Three Phase Induction Ac Electric Motor With high quality best price

our products are selling well in the American, European, South American and Asian markets. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Model Number:

-

631-4/0.12KW

- Type:

-

Asynchronous Motor

- Frequency:

-

50HZ

- Phase:

-

three-phase

- Certification:

-

CCC, ce

- AC Voltage:

-

220/380V

Slip clutch: this type uses a slip clutch on the driven end yoke which is comprised of three steel plates in line held together with a series of bolts with springs under the nuts. The idea here is that when you tighten the nuts the pressure is increased onto the centre plate which when set up for the load will allow the shaft to turn and the implement to stall, absorbing the shock load. As mine is rated from 20-40 hp and I’m running a 17 hp I had to make alterations to set it up. Through trial and error I determined that I had to remove half the tension bolts and springs and back off the remainder nuts to minimum in order for the clutch to “slip” prior to stall on the tractor.

- Color:

-

Silverr plastic coating

- Product Name:

-

Y2 Series Ac Motor

We distribute many other items that are not listed above, but are still readily available. Feel free to give us a call or send us an email. We are always ready to help.

Supply Ability

- Supply Ability:

- 15000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Each in carton box,then packed in wooden case.

- Port

- NINGBO/SHANGHAI

Online Customization

The company was certified by ISO9001:2008 Quality Management System.

Y2 Series Three Phase Induction Ac Electric Motor

| Product Name | Y2 Series Three Phase Induction Ac Electric Motor |

| Color | Silverr plastic coating |

| frequency | 50HZ |

1. Can your factory accept OEM or ODM?

Yes,we have OEM & ODM for more than 22 years.

2.Can you offer sample?

Yes,we can offer Free samples for VIP.

3.How about your requirement for MOQ.?

We have very low requirement on Min. Order Quantity.

4.Do your factory offer quality warranty?

Yes,quality warrantee is guaranteed.

5.Do your factory offer trade assurance?

Certainly,we have trade assurance program support.

6.Do your factory accept distribution agent?

Yes, distribution agent is warmly welcomed.

Aluminum shop made in China – replacement parts – in Naples Italy Housing 1.5kw 2HP Three Phase AC Induction Motor with top quality

We – EPG Team the biggest gearbox & motors , couplings and gears manufacturing facility in China with 5 diverse branches. For far more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

Solution Description:

AC Motor is a unit that transforms the electrical strength of alternating recent into mechanical vitality. The AC Motor is mostly composed of an electromagnet winding or stator winding for creating magnetic field and a rotating armature or rotor. The motor is manufactured by the phenomenon that the electrical coil is forced to rotate in the magnetic subject. AC motors are divided into two varieties: synchronous alternating existing motor and induction motor.

The stator windings of a few-period AC motors are generally 3 coils divided by a hundred and twenty levels, which are linked by triangle or star. When three-stage present is used, a magnetic discipline is produced in each and every coil, and the a few magnetic fields are mixed to form a rotating magnetic area.

High voltage ac motors are designed with the software of modern engineering resulting in compact machines showcasing outstanding dynamic houses, meeting the most significant application in locations that consist of automation and process manage.

Besides offering dependability and substantial performance, which will assure lengthy working periods without demanding any servicing, the New high voltage ac motors current excellent operating features, which include:

•Wide velocity variation variety

•Dimensions as for each GB and IEC Requirements

•High performance

•Low noise level

•High second of inertia

•High potential to dynamic masses

•Rugged design

•High vibration resistance

•Excellent commutation good quality

Product Parameters:

| Merchandise Title | aluminum housing 1.5KW 2hp three section AC induction motor |

| Motor Sort | DC Motor,AC Motor,Stepper Motor,Asynchronous Motor ,Synchronous Motor (Electric powered machinery) |

| Rotational Speed |

Low Speed/Continuous Velocity/High Pace/Variable Speed |

| Stator Section Variety |

3-Phase/Single-Period |

| Common Attributes | •NEMA Premium Effectiveness Stage according to NEMA Y •Three-section, fifty, 60 Hz •Voltage: 3000 to 11000 V •Rated output: up to 12500 kw •Number of poles: 2 ,4,6,8,10 or 12poles •Frame sizes: 450 mm to 630mm •Cast aluminium squirrel cage for rotor •Degree of security: IP23 to IP54(Completely enclosed) •Class insulation F with class (120ºC) temperature rise •Grease nipples for frame 450 to 630MM •Continuous Duty (S1) •With thermal protection PTC140 ºC or PT100 •Larger diameter shafts for the optimum overhung load scores in the industry •Oversized roller bearings for maximum load capacity •Other optional attributes beneath ask for |

| AC Motor | AC Motors can run in large temperature, flammable and other environments, and do not need to cleanse the dust of carbon brushes routinely, but it is difficult to management the speed, simply because it is necessary to manage the frequency of AC motors (or use induction motors, enhance inside resistance, decrease the motor velocity at the exact same AC frequency. Speed, control the voltage will only affect the torque of the motor. The voltage of the general civil motor has two varieties, this sort of as 110V and 220V, and there are 380V or 440V in industrial software. |

| Software | AC Motors have larger wor ept efficiency, no smoke, odor, no pollution to the environment, and much less noise. Due to the fact of its collection of positive aspects, it is broadly utilized in industrial and agricultural generation, transportation, countrywide defense, commercial and household appliances, health care appliances and other fields. For Instance: •Compressor •Rubber mixer •Fans and Pumps •Air brower •Coal mill and rolling mill •Crushers •Conveyor belts •Centrifugal equipment •Lathe •Hoist |

Solution Demonstrate

The use of first tools manufacturer’s (OEM) part quantities or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our business and the detailed substitute areas contained herein are not sponsored, authorized, or manufactured by the OEM.

Three wholesaler made in China – replacement parts – in Edinburgh United Kingdom Phase AC Induction Constant Speed Motor with top quality

We – EPG Group the biggest gearbox & motors , couplings and gears manufacturing unit in China with 5 distinct branches. For far more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

Creation Description

YPT series motor using pc aided layout engineering, in get to make the motor can adapt to the SPWM and PWM electricity

position, has been made in the layout of special consideration of the stator, rotor slot and the stator winding distribution, in purchase

to obtain a appropriate inductor value, to handle and reduce the adverse effects of harmonics generated the.

| Sort |

YPT |

| Electricity |

.75~315kw |

| Insulation |

F / B, H/B |

| Voltage and frequency |

380/four hundred/415/660/690V 50/60hz |

| Pace |

3000/1500/a thousand/750/600 rpm |

| Mounitng |

IMB3/IMV1 |

| Cooling and ventilation |

IC416 |

| Winding |

100% Cooper Wire |

| Protection class |

IP54 |

| Vibration |

vibration class A, vibration class B is available on request. |

| Quality assurance |

obey ISO9001 documented quality system. |

| Site conditions |

from -15°C t0 +40°C and altitude below 1000 meters |

Products Application, Value Added Service

PinnxunMotor can provide a complete set of optimal solutions for various Applications,Bring innovation and valueadded to our

buyers, At the same time, we can also formulate special solutions according to the different needed of customer

Product Process

Pinnxun always just take excellent faith, responsibility, carefulness and excellence as our administration philosophy,committedto delivering

clients with exceptional good quality items,every single action in processs need to be take full interest.

Qualification certification program

The crucial for ‘Pinxing’ prolonged-phrases cooperation is to repeatedly boost the quality of is goods and services, By virtue of is

extensive method, high quality management program and rigid compliance with intercontinental mainstream standards.’Pinxing’

has established a good quality management method that has handed ISO9001-2008 Top quality administration method certification

ISO14001 Environmental management method.

ISO9001-2008 High quality management technique

ISO14001 Environmental administration system

CE European Certification

IECEX Globally Ex Certification for Ex motors

ATEX European Ex Certification for Ex motors

EAC Russia GOST common Ex certification for Ex motors

CQC China good quality center strength conservation certification

Around the world Marketing and advertising & Support Network

Global Perfect Advertising services community is one particular of Pinxing’s advantage. we have 38 branches in china principal town,5 branches in

the Overseas ,Our company penetrates a lot more than sixty nations and locations which includes South The usa, North The united states,Europe, Asia,

Center East and Africa, Offering us quick attain capability from product sales, service, procurement and Transportation since inception, Pinxing

always uphold the improvement strategy of marketplace globalization. we segment and place clients wants and ept marketplace. our

products and provider are broadly utilized in global sector, and functionality steady and security.we custom various motors for diverse

industries

The use of original products manufacturer’s (OEM) element quantities or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating solution use and compatibility. Our business and the detailed substitution components contained herein are not sponsored, accepted, or made by the OEM.