Product Description

Product Description

-K Series Helical Bevel Gearbox

K series gear reducer, manufactured according to international technical requirements, has a high scientific and technological content; Space saving, reliable and durable, high overload capacity, power up to 132KW; Low energy consumption, superior performance, reducer efficiency up to 95%

It is designed and manufactured on the basis of module combination system. There are a lot of motor combinations, installation forms and structural schemes. The transmission ratio is classified carefully to meet different operating conditions and realize electromechanical integration.

High transmission efficiency, low energy consumption and superior performance.

Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface is carburized, quenched and hardened, and the gear is finely ground. It features stable transmission, low noise, large bearing capacity, low temperature rise, and long service life. Performance and characteristics:

1. The gear is carburized and quenched with high-quality alloy, the hardness of the tooth surface is up to 60 ± 2hrc, and the grinding accuracy of the tooth surface is up to 5-6

2. The computer modification technology is used to pre modify the gear, which greatly improves the bearing capacity of the reducer

3. Complete modular structure design is adopted from the box to the internal gear, which is suitable for large-scale production and flexible selection

4. The standard reducer models are divided according to the form of decreasing torque. Compared with the traditional equal proportion division, they are more in line with customer requirements and avoid power waste

5. It is designed and manufactured by cad/cam to ensure the stability of quality

6. Multiple sealing structures are adopted to prevent oil leakage

7. Multi directional noise reduction measures to ensure the excellent low noise performance of the reducer

8. The installation mode of Liyi products is flexible, which makes it easy for customers to choose K57 reducer, K67 reducer, K77 reducer, K87 reducer, K97 reducer, KA87 reducer, KA97 reducer, KA107 reducer, KA127 reducer

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Marine, Agricultural Machinery, Car, Packing Machine, Food Process, Lift, Crane, Agita |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Samples: |

US$ 800/Piece

1 Piece(Min.Order) | |

|---|

Lubrication Practices for Extending the Lifespan of Agricultural Gearboxes

Proper lubrication is essential for ensuring the longevity and optimal performance of agricultural gearboxes. Here are some essential lubrication practices that can help extend the lifespan of these gearboxes:

- Choose the Right Lubricant: Select a high-quality lubricant specifically designed for gearboxes and agricultural machinery. Consider factors such as viscosity, temperature range, and load-bearing capacity to ensure compatibility with the gearbox’s operating conditions.

- Regular Inspection: Perform regular visual inspections of the gearbox and lubricant to check for signs of contamination, wear, or inadequate lubrication. Address any issues promptly to prevent further damage.

- Cleanliness: Maintain a clean environment around the gearbox to minimize the risk of dirt, debris, and moisture entering the gearbox housing. Contaminants can compromise the lubricant’s effectiveness and accelerate wear.

- Lubricant Level: Monitor and maintain the proper lubricant level in the gearbox. Insufficient lubrication can lead to increased friction and heat, causing premature wear and potential damage to gears and bearings.

- Replace Lubricant: Follow the manufacturer’s recommendations for lubricant change intervals. Over time, lubricants can degrade, lose their properties, and become contaminated. Regularly replacing the lubricant helps ensure optimal performance.

- Use Lubrication Schedule: Create a lubrication schedule based on the gearbox’s usage and operating conditions. Stick to the recommended intervals for applying or changing lubricant to prevent under-lubrication or over-lubrication.

- Appropriate Lubrication Method: Follow the manufacturer’s guidelines for the correct lubrication method, whether it’s through oil bath, grease, or automatic lubrication systems. Proper application ensures even distribution of lubricant across gear surfaces.

- Temperature Considerations: Be aware of temperature variations in your operating environment. Extreme temperatures can affect lubricant viscosity and performance. Choose a lubricant that can handle the temperature range of your equipment.

- Expert Advice: Consult the gearbox manufacturer or a lubrication specialist to determine the best lubrication practices for your specific agricultural gearbox model and application.

By adhering to these lubrication practices, farmers can maximize the lifespan of their agricultural gearboxes, minimize downtime, and ensure efficient and reliable operation of their equipment.

Specific Safety Precautions for Agricultural Gearbox Operation

Operating agricultural machinery with gearboxes requires careful attention to safety to prevent accidents and ensure the well-being of operators and bystanders. Here are some specific safety precautions associated with agricultural gearbox operation:

- Read the Manual: Familiarize yourself with the manufacturer’s manual for the specific gearbox and machinery. It provides valuable information about proper operation, maintenance, and safety guidelines.

- Proper Training: Ensure that operators are trained in the safe operation of the machinery, including how to engage and disengage the gearbox, adjust speeds, and handle emergencies.

- Protective Gear: Operators should wear appropriate protective gear, such as helmets, gloves, safety goggles, and sturdy footwear, to reduce the risk of injury from debris, moving parts, or other hazards.

- Clear Workspace: Before operating the machinery, clear the area of obstacles, debris, and bystanders. Ensure a safe distance between the machinery and people.

- Secure Attachments: If the gearbox is used in conjunction with attachments, ensure that they are properly secured and mounted according to manufacturer guidelines to prevent detachment during operation.

- Engage Safely: Engage the gearbox and start the machinery only after ensuring that all personnel are at a safe distance and that the machinery is on stable ground.

- Avoid Loose Clothing: Operators should avoid wearing loose clothing or accessories that could get caught in moving parts.

- Emergency Stops: Familiarize yourself with the location of emergency stop buttons and switches on the machinery and be prepared to use them if needed.

- Regular Maintenance: Perform routine maintenance checks on the gearbox and machinery to ensure that all components are in proper working condition. Replace worn parts and lubricate components as recommended by the manufacturer.

- Shut Down Properly: When finishing a task, disengage the gearbox, shut off the machinery, and engage any safety locks to prevent accidental starts.

Following these safety precautions can greatly reduce the risk of accidents and injuries when operating agricultural machinery with gearboxes. Always prioritize safety to create a secure working environment for everyone involved.

Maintenance Requirements for Agricultural Gearboxes

Maintaining agricultural gearboxes is crucial to ensure the smooth and efficient operation of farming equipment. Proper maintenance helps extend the lifespan of gearboxes and prevents costly breakdowns. Here are the key maintenance requirements:

- Regular Inspections: Conduct routine visual inspections to check for signs of wear, damage, leaks, or misalignment. Regularly inspect gear teeth, seals, and bearings for any issues.

- Lubrication: Proper lubrication is essential to minimize friction and wear in gearboxes. Follow the manufacturer’s guidelines for the type of lubricant to use and the recommended intervals for lubrication.

- Lubricant Checks: Monitor the gearbox’s lubricant levels and quality regularly. Replace or replenish lubricants as needed, and ensure that contaminants are kept out of the lubrication system.

- Tightening Bolts and Fasteners: Check and tighten bolts, nuts, and fasteners to prevent loosening due to vibrations during operation. Loose components can lead to misalignment and premature wear.

- Seal Inspection: Examine seals for leaks and proper sealing. Damaged or worn seals should be replaced promptly to prevent lubricant leakage and the ingress of contaminants.

- Cleaning: Keep gearboxes clean by removing dirt, debris, and residue. Regular cleaning prevents abrasive particles from entering the gearbox and causing damage.

- Alignment: Ensure that gearboxes are properly aligned with connected components, such as shafts and couplings. Misalignment can lead to increased wear and reduced efficiency.

- Temperature Monitoring: Monitor the operating temperature of the gearbox. Abnormal temperature increases may indicate issues like overloading or insufficient lubrication.

- Filter Replacement: If the gearbox has a filtration system, regularly replace or clean the filters to prevent contaminants from entering the gearbox.

- Expert Inspection: Periodically have gearboxes inspected by qualified technicians. They can identify potential problems that may not be visible during routine inspections.

Adhering to these maintenance requirements ensures that agricultural gearboxes remain in optimal condition and contribute to the reliability and efficiency of farming equipment. Regular maintenance not only prevents unexpected downtime but also prolongs the service life of the gearboxes, ultimately benefiting the productivity of agricultural operations.

editor by CX 2024-02-04

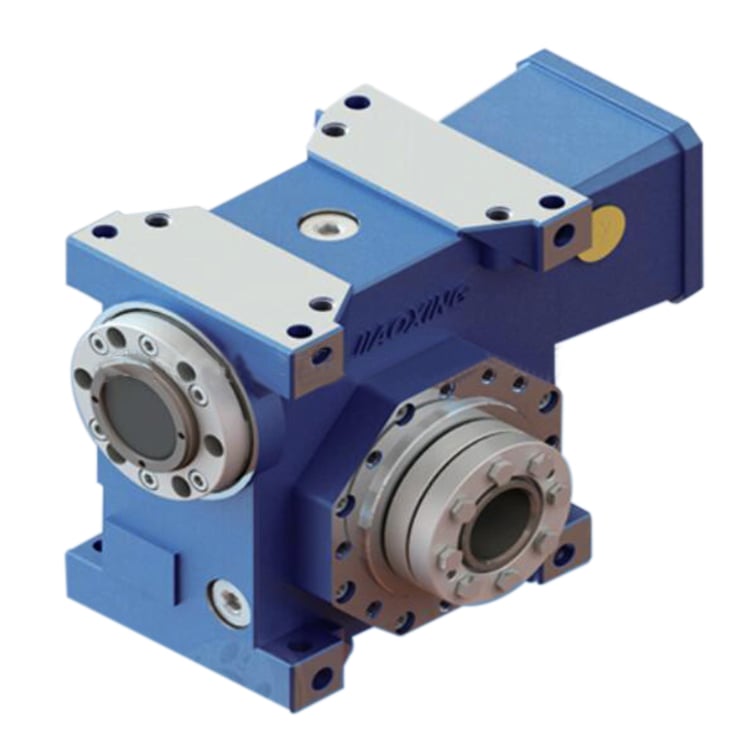

China Best Sales Right Angle Cubic Spiral Bevel Gearbox for Servo Motor sequential gearbox

Product Description

For over 12 years, spiral bevel gearboxes from SIJIE have been the market leader for high-quality, reliable, versatile right-angle gearboxes.

We can also manufacture a special bevel gearbox to fit all your demands of the application.

SIJIE spiral bevel gearboxes are offered in 8 types of housing sizes and 6 types of gear ratios, which can be constructed with lots of shaft configurations and oriented in any direction to easily integrate into your machine design.

All the shaft configurations are suitable for Casting iron, stainless steel, and aluminum version bevel gearboxes.

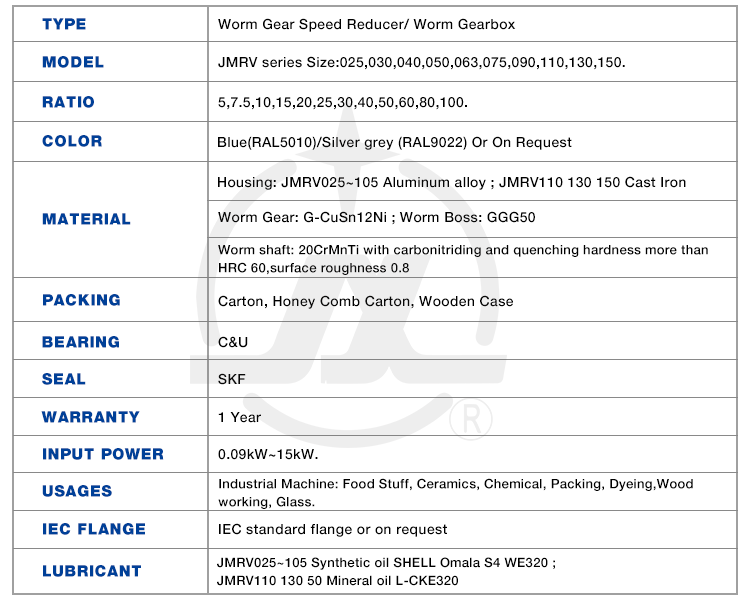

Spiral Bevel Gearbox Specifications

| Model | Input Speed (RPM) | Gear Ratio 1:1 | Gear Ratio 2:1 | Gear Ratio 3:1 | Gear Ratio 4:1 | Gear Ratio 5:1 | |||||

| Power | Torque | Power | Torque | Power | Torque | Power | Torque | Power | Torque | ||

| ( KW ) | ( N.m ) | ( KW ) | ( N.m ) | ( KW ) | ( N.m ) | ( KW ) | ( N.m ) | ( KW ) | ( N.m ) | ||

| SJV-090 | 2000 | 7.55 | 33.6 | 4.2 | 38.57 | 2.85 | 40.39 | 2.15 | 39.76 | 1.4 | 34.56 |

| 1500 | 6 | 38.2 | 3.35 | 42.66 | 2.2 | 42.02 | 1.65 | 42.02 | 1.1 | 35.02 | |

| 1000 | 4.3 | 41.07 | 2.35 | 44.89 | 1.5 | 43.02 | 1.15 | 43.93 | 0.75 | 35.81 | |

| 750 | 3.4 | 43.29 | 1.8 | 45.84 | 1.2 | 45.84 | 0.87 | 44.19 | 0.58 | 36.93 | |

| SJV-110 | 2000 | 13.8 | 63 | 7.9 | 72 | 5.6 | 80 | 3.75 | 70.1 | 2.95 | 71.3 |

| 1500 | 11 | 70 | 6.3 | 80.2 | 4.45 | 85 | 2.9 | 73.9 | 2.35 | 74.8 | |

| 1000 | 7.87 | 75 | 4.45 | 85 | 3.1 | 88.8 | 2 | 76.4 | 1.6 | 76.4 | |

| 750 | 6.15 | 78.3 | 3.45 | 87.9 | 2.4 | 91.7 | 1.55 | 78.9 | 1.25 | 79.6 | |

| SJV140 | 2000 | 29.9 | 128.6 | 14.1 | 133.3 | 10.1 | 136.8 | 6.8 | 125.3 | 5.05 | 115.2 |

| 1500 | 23.9 | 152.2 | 11.1 | 141.3 | 7.95 | 151.8 | 5.3 | 135 | 3.95 | 125.7 | |

| 1000 | 17.2 | 164.3 | 7.85 | 149.9 | 5.6 | 160.4 | 3.75 | 143.3 | 2.75 | 131.3 | |

| 750 | 13.4 | 170.6 | 6.2 | 157.9 | 4.4 | 168.1 | 2.95 | 150.3 | 2.1 | 133.7 | |

| SJV-170 | 2000 | 49.2 | 180.1 | 26.2 | 224.7 | 18.2 | 235.2 | 10.5 | 179.5 | 8.05 | 170.9 |

| 1500 | 39.3 | 250.2 | 20.8 | 264.9 | 14.4 | 275 | 8.4 | 213.9 | 6.45 | 205.3 | |

| 1000 | 28.8 | 275 | 14.9 | 284.6 | 10.1 | 289.4 | 5.9 | 225.4 | 4.5 | 214.9 | |

| 750 | 22.8 | 290.3 | 11.6 | 295.4 | 7.8 | 298 | 4.55 | 231.7 | 3.45 | 219.7 | |

| SJV-210 | 2000 | 84 | 336.7 | 52.4 | 480.2 | 34.9 | 428.3 | 23.3 | 417.6 | 15.9 | 350.2 |

| 1500 | 67.5 | 429.8 | 43.2 | 550.1 | 27.7 | 529.1 | 18.5 | 471.1 | 12.7 | 404.3 | |

| 1000 | 50.5 | 482.3 | 31.4 | 599.7 | 20 | 573 | 13.4 | 511.9 | 9 | 429.8 | |

| 750 | 40.8 | 519.5 | 25.2 | 641.8 | 15.7 | 599.7 | 10.4 | 529.7 | 6.95 | 442.5 | |

| SJV-240 | 2000 | 111 | 475.8 | 71.5 | 643.7 | 52.4 | 695.2 | 37.7 | 652.3 | 28.9 | 643.8 |

| 1500 | 90.5 | 576.2 | 58.5 | 744.9 | 41.9 | 800.3 | 30.2 | 769.1 | 23.4 | 744.9 | |

| 1000 | 68 | 649.4 | 41.9 | 800.3 | 30.2 | 865.2 | 21.7 | 828.9 | 16.4 | 783.1 | |

| 750 | 54.5 | 694 | 33.8 | 860.8 | 23.6 | 901.5 | 17.1 | 871 | 13 | 827.7 | |

| SJV-280 | 2000 | 168 | 837.5 | 107 | 961.4 | 73 | 957 | 47.6 | 870.4 | 39.4 | 890.5 |

| 1500 | 156 | 993.2 | 88 | 1121 | 58.5 | 1117 | 38.5 | 980.5 | 31.4 | 999.6 | |

| 1000 | 115 | 1098 | 64.5 | 1232 | 42.4 | 1215 | 27.5 | 1051 | 22.4 | 1070 | |

| 750 | 94.2 | 1199 | 51 | 1299 | 33.5 | 1280 | 21.7 | 1105 | 17.7 | 1127 | |

Company Informations:

Factory Apprarance Production Workshop

Assembly Workshop Inventory Workshop

SIJIE Team Gearbox Shipment

Why SIJIE cubic spiral bevel gearbox?

1: High-quality, low Backlash, quiet noise, smooth running, high torque bevel gearbox professional manufacturer since 2008.

2: The wide range of bevel gearbox product lines can meet the application needs of customers to the greatest extent.Gearbox housing size is from 065 to 280. Casting iron, stainless steel, and aluminum version gearboxes can be manufactured according to customers’ requirements.

3: Strict quality control has been from the beginning to end at SIJIE. All the cubic bevel gearboxes will be tested in our factory accordingto the more than 30 items checking list before shipping.

4: SIJIE cubic type bevel gearbox has 13 months warranty period, during the warranty period, any problem with “SIJIE” products,after we confirmed, we will guide the customer to fix or ship a new 1 to replace it in 1-3 working days.

5: SIJIE kept a large inventory of cubic spiral bevel gearbox parts to make sure all the standard orders can be shipped in 7 working days.

6: Our Experienced Engineer Team can design the bevel gearbox drawings to fit all your demands in 2 hours. Small-quantity OEM/ODM orders also can be accepted by SIJIE. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Hardness: | Hardened Tooth Surface |

| Step: | Single-Step |

| Gear Ratios: | 1:1, 2:1, 3:1, 4:1, 5:1 |

| Configurations: | 2-Way, 3-Way, 4-Way Shafts |

| Samples: |

US$ 95/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Lubrication Practices for Extending the Lifespan of Agricultural Gearboxes

Proper lubrication is essential for ensuring the longevity and optimal performance of agricultural gearboxes. Here are some essential lubrication practices that can help extend the lifespan of these gearboxes:

- Choose the Right Lubricant: Select a high-quality lubricant specifically designed for gearboxes and agricultural machinery. Consider factors such as viscosity, temperature range, and load-bearing capacity to ensure compatibility with the gearbox’s operating conditions.

- Regular Inspection: Perform regular visual inspections of the gearbox and lubricant to check for signs of contamination, wear, or inadequate lubrication. Address any issues promptly to prevent further damage.

- Cleanliness: Maintain a clean environment around the gearbox to minimize the risk of dirt, debris, and moisture entering the gearbox housing. Contaminants can compromise the lubricant’s effectiveness and accelerate wear.

- Lubricant Level: Monitor and maintain the proper lubricant level in the gearbox. Insufficient lubrication can lead to increased friction and heat, causing premature wear and potential damage to gears and bearings.

- Replace Lubricant: Follow the manufacturer’s recommendations for lubricant change intervals. Over time, lubricants can degrade, lose their properties, and become contaminated. Regularly replacing the lubricant helps ensure optimal performance.

- Use Lubrication Schedule: Create a lubrication schedule based on the gearbox’s usage and operating conditions. Stick to the recommended intervals for applying or changing lubricant to prevent under-lubrication or over-lubrication.

- Appropriate Lubrication Method: Follow the manufacturer’s guidelines for the correct lubrication method, whether it’s through oil bath, grease, or automatic lubrication systems. Proper application ensures even distribution of lubricant across gear surfaces.

- Temperature Considerations: Be aware of temperature variations in your operating environment. Extreme temperatures can affect lubricant viscosity and performance. Choose a lubricant that can handle the temperature range of your equipment.

- Expert Advice: Consult the gearbox manufacturer or a lubrication specialist to determine the best lubrication practices for your specific agricultural gearbox model and application.

By adhering to these lubrication practices, farmers can maximize the lifespan of their agricultural gearboxes, minimize downtime, and ensure efficient and reliable operation of their equipment.

Types of Farming Equipment Incorporating Agricultural Gearboxes

Agricultural gearboxes play a vital role in various farming equipment, enhancing their efficiency and enabling them to perform essential tasks. Here are some types of farming equipment that commonly incorporate agricultural gearboxes:

- Tractors: Agricultural gearboxes are integral components of tractors, contributing to power transmission from the engine to various attachments such as plows, harrows, and mowers.

- Harvesters: Harvesters, used to gather crops like grains, fruits, and vegetables, utilize gearboxes to drive conveyor systems and separators, ensuring smooth and efficient harvesting operations.

- Planters and Seeders: Planters and seeders rely on gearboxes to precisely distribute seeds and fertilizers while maintaining the desired planting depth.

- Sprayers: Agricultural gearboxes are used in sprayers to drive pumps that distribute pesticides, herbicides, and fertilizers over fields.

- Hay Balers: Gearboxes are essential in hay balers for compacting and forming bales of hay, enabling easy storage and transportation.

- Manure Spreaders: Manure spreaders incorporate gearboxes to distribute and spread fertilizers and compost evenly across fields.

- Grain Augers: Grain augers, used for loading and unloading grains, feature gearboxes to drive the rotating screw mechanism that lifts and transfers grains.

- Cultivators: Cultivators use gearboxes to drive rotating tines or blades that loosen and prepare the soil for planting.

- Rotary Cutters: Rotary cutters, often attached to tractors, utilize gearboxes to power the spinning blades used for cutting tall grass, weeds, and brush.

- Threshers: Threshers, employed for separating grains from their husks or stalks, incorporate gearboxes to drive the threshing mechanisms.

These examples demonstrate the diverse applications of agricultural gearboxes across a wide range of farming equipment. By providing reliable power transmission and control, agricultural gearboxes contribute significantly to the productivity and efficiency of modern agricultural practices.

Maintenance Requirements for Agricultural Gearboxes

Maintaining agricultural gearboxes is crucial to ensure the smooth and efficient operation of farming equipment. Proper maintenance helps extend the lifespan of gearboxes and prevents costly breakdowns. Here are the key maintenance requirements:

- Regular Inspections: Conduct routine visual inspections to check for signs of wear, damage, leaks, or misalignment. Regularly inspect gear teeth, seals, and bearings for any issues.

- Lubrication: Proper lubrication is essential to minimize friction and wear in gearboxes. Follow the manufacturer’s guidelines for the type of lubricant to use and the recommended intervals for lubrication.

- Lubricant Checks: Monitor the gearbox’s lubricant levels and quality regularly. Replace or replenish lubricants as needed, and ensure that contaminants are kept out of the lubrication system.

- Tightening Bolts and Fasteners: Check and tighten bolts, nuts, and fasteners to prevent loosening due to vibrations during operation. Loose components can lead to misalignment and premature wear.

- Seal Inspection: Examine seals for leaks and proper sealing. Damaged or worn seals should be replaced promptly to prevent lubricant leakage and the ingress of contaminants.

- Cleaning: Keep gearboxes clean by removing dirt, debris, and residue. Regular cleaning prevents abrasive particles from entering the gearbox and causing damage.

- Alignment: Ensure that gearboxes are properly aligned with connected components, such as shafts and couplings. Misalignment can lead to increased wear and reduced efficiency.

- Temperature Monitoring: Monitor the operating temperature of the gearbox. Abnormal temperature increases may indicate issues like overloading or insufficient lubrication.

- Filter Replacement: If the gearbox has a filtration system, regularly replace or clean the filters to prevent contaminants from entering the gearbox.

- Expert Inspection: Periodically have gearboxes inspected by qualified technicians. They can identify potential problems that may not be visible during routine inspections.

Adhering to these maintenance requirements ensures that agricultural gearboxes remain in optimal condition and contribute to the reliability and efficiency of farming equipment. Regular maintenance not only prevents unexpected downtime but also prolongs the service life of the gearboxes, ultimately benefiting the productivity of agricultural operations.

editor by CX 2024-01-02

China Professional R Series Helical Bevel Gear Box/Gearbox with Motor/Use of Helical Gear Box agricultural right angle gearbox

Product Description

Product Advantages

| Size | R37 | R57 | R77 | R87 | R107 |

| Ratio | 3.41-134.82 | 4.39-782 | 5.31-1430 | 5.3-2873 | 6.66-7583 |

| Power | 0.12KW-3KW | 0.12KW-7.5KW | 0.12KW-11KW | 0.12KW-18.5KW | 0.12KW-18.5KW |

| Output torque | 30-205N.M | 40-400N.M | 50-795N.M | 50-1610N.M | 80-4870N.M |

| Output speed(RPM) | 0.1-821RPM | 0.1-660RPM | 0.1-795RPM | 0.1-276RPM | 0.1-220RPM |

R series reducer has the characteristics of small volume and large torque transmission. It is designed and manufactured on the basis of modular combination system. There are many motor combinations,installation forms and structural schemes. R series reducer adopts the modular design principle of unit structure, with high transmission efficiency, low energy consumption and superior performance.

Product Description

Detailed Photos

Our Advantages

| Application: | Motor, Motorcycle, Machinery, Agricultural Machine, Lift |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Layout: | Expansion, Parallel |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | |

|---|

Agricultural Gearboxes

There are several types of agricultural gearboxes, and they are used in various applications. Among them are Bevel gearboxes, CZPT speed gearboxes, and Worm gear speed reducers. If you’re looking for a reliable, high-performing agricultural gearbox, you’ve come to the right place. Read on to learn more about these gearboxes. Also, check out our guide to bevel gearboxes.

Bevel gearboxes

The fatigue life of bevel gearboxes in agricultural equipment is determined by the cumulative damage sums for different operations. A simulation model was used to assess the fatigue life of a spiral bevel gear. The accumulated damage sums for each operation were shown in figure 9a. The subsoiler tillage operation exceeded the damage sum of one. This criterion indicates that the fatigue life of a gearbox is shorter than its service life.

In bevel gearboxes, the second shaft has two shafts that are connected to each other. One shaft is mounted to the outer surface of the housing 3 through bearings, while the other shaft has a flange that protrudes into the gear housing. The second shaft is attached via bearings on the gear housing and flange. It is mounted in this way to allow the bevel gear to rotate smoothly.

CZPT speed gearboxes

If you are an agricultural machine owner, you know that the right speed agricultural gearboxes can make the difference between a profitable crop harvest or a disaster. Today’s agricultural machinery can be found in a variety of applications, including for crop and animal production. Many of these applications require heavy-duty gearboxes with large capacity. The quality of these agricultural gearboxes depends on the quality of their bearings, which are important to the longevity of your equipment.

Industrial CZPT gearboxes can be repaired and overhauled by qualified and experienced technicians at CZPT Products. CZPT gearboxes can be repaired or rebuilt at significant savings. For industrial uses, the RAR model is perfect for applications where space is a consideration. Industrial CZPT gearboxes are available in multiple sizes and types, and they can be customized to meet your unique needs. For the best price and service, contact CZPT Products today!

CZPT speed bevel gearboxes

The demand for food has skyrocketed since the 2010 global financial crisis, and while the world’s population is still rising, at a slower rate, land is not. This is forcing agricultural machinery manufacturers to come up with innovative solutions to maximize the use of available land. The need for agricultural machinery is also growing due to shorter cropping cycles and wear and tear on equipment. CZPT gearbox manufacturers are meeting this demand with high-quality products.

A number of benefits make CZPT speed bevel gearboxes the preferred choice for agricultural applications. In addition to its renowned performance, the product’s design has been adapted for use in agricultural and glass machinery. The result is a unit with low backlash and high transmission. Moreover, the CZPT model is the best all-rounder among servo right-angle gearboxes.

editor by CX 2023-05-22

China Right Angle Gear Box Pto Farm Rotary Slasher Feeder Mixer Rotary Tiller Cultivator Baller Tractor Agricultural Machinery Parts Bevel Gearbox agricultural gearboxes

Item Description

Solution Description

Organization Profile

In 2571, HangZhou CZPT Machinery Co.,ltd was set up by Ms. Iris and her 2 associates(Mr. Tian and Mr. Yang) in HangZhou town(ZHangZhoug province, China), all 3 Founders are engineers who have more than averaged 30 a long time of expertise. Then because the requirements of business expansion, in 2014, it moved to the present Xihu (West Lake) Dis. Industrial Zone (HangZhou town, ZHangZhoug province, China).

Through our effectively-known brand ND, CZPT Machinery provides agricultural answers to agriculture machinery producer and distributors around the world by means of a entire line of spiral bevel gearboxes, straight bevel gearboxes, spur gearboxes, drive shafts, sheet steel, hydraulic cylinder, motors, tyre, worm gearboxes, worm operators etc. Goods can be customized as request.

We, CZPT equipment set up a total top quality management technique and sales services community to offer customers with substantial-top quality items and satisfactory support. Our goods are marketed in forty provinces and municipalities in China and 36 countries and regions in the planet, our principal industry is the European market place.

Certifications

Our Manufacturing facility

Sample Area

Why select us?

one) Customization: With a sturdy R&D crew, and we can develop merchandise as essential. It only requires up to 7 days for us to design and style a established of drawings. The manufacturing time for new merchandise is typically 50 times or much less.

two) Good quality: We have our personal total inspection and testing tools, which can ensure the high quality of the goods.

3) Potential: Our annual creation ability is in excess of five hundred,000 sets, also, we also take little quantity orders, to satisfy the requirements of diverse customer’s obtain quantities.

four) Services: We concentrate on offering high-top quality products. Our merchandise are in line with worldwide requirements and are mostly exported to Europe, Australia, and other countries and areas.

5) Shipment: We are shut to HangZhou and ZheJiang ports, to offer the swiftest delivery support.

Packaging & Transport

FAQ

Q: Are you a investing business or producer?

A: We’re manufacturing facility and providing gearbox ODM & OEM providers for the European market place for far more than ten years

Q: Do you provide samples? is it free or further?

A: Sure, we could supply the sample for cost-free demand but do not shell out the cost of freight.

Q: How lengthy is your shipping and delivery time? What is your phrases of payment?

A: Generally it is 40-45 times. The time could differ depending on the product and the level of customization.

For regular items, the payment is: 30% T/T in advance,balance just before cargo.

Q: What is the exact MOQ or price tag for your item?

A: As an OEM firm, we can offer and adapt our goods to a broad range of needs.

Thus, MOQ and price tag might tremendously range with dimensions, content and even more technical specs For instance, expensive goods or common merchandise will typically have a reduce MOQ. Make sure you get in touch with us with all related particulars to get the most precise quotation.

If you have an additional question, you should come to feel free of charge to get in touch with us.

|

US $10-300 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Straight or Spiral Bevel Gear |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

###

| Customization: |

Available

|

|---|

|

US $10-300 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Straight or Spiral Bevel Gear |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

###

| Customization: |

Available

|

|---|

Choosing the Right Agricultural Gearbox

When buying an agricultural gearbox, there are a few things to consider. The quality of materials, functionality, and mechanism are crucial factors to durability. A durable device will ensure that you won’t have to keep replacing it. Here are some tips to help you select the right one. Let’s begin. Read on to learn more about the different features available in agricultural gearboxes. Listed below are a few of the most important factors to consider.

Bevel gearboxes

Agricultural gearboxes are essential to the entire food cycle. If your gears are not in good shape, you will be unable to meet the demand and you will suffer from heightened downtime. Fortunately, there are numerous quality bevel gearboxes available on the market today. In fact, the CZPT Gearbox Company supplies bevel gearboxes for agricultural applications. Here are some of the reasons you should choose the right one.

A bevel gearbox is a single-stage unit that interlocks bevelled edges on two gears to transfer torque and rotation. These gears can be either straight or helical. This type of gearbox is inexpensive to produce and operates quietly. It also has lower transmittable torque. Bevel gearboxes are often used as a low-cost alternative to hypoid gearboxes.

Agricultural bevel gearboxes are used in various applications, including hay balers, combine harvesters, seeders, and plows. These gears are well-suited for use with offset rotary fillers. They offer reduction ratios of up to 2.44 and cast iron cases. They are commonly known as “right-angle gearboxes” or “Parallel SHAFT gearboxes.”

Agricultural bevel gearboxes come in many sizes and ratios. In general, higher sizes are made of closed-grain cast-iron. Other materials, such as SG 500/7, are used for larger sizes. The main gear and each drive gear are mesh-mounted, and the shafts are designed to rotate in either direction. They have oil seals on the joints. The Spiral Bevel Gearbox is best suited for FG60 or FG75 motors.

The RINV-OP65 right-angle angular gearbox comes with an optional electronic or mechanical position indicator. Its angular design allows for changes in axis rotation, and provides smooth power transmission with minimal backlash. Premium gearmotors include hardened spiral bevel gears and stainless steel shafts for quiet operation. They are available in various ratios and shaft styles. If you want to choose one, make sure it is made to fit the needs of the machine.

Closed-loop seals

There are a number of reasons to install closed-loop seals in an agricultural gearbox. The first is the need to isolate the gearbox from the atmosphere, an important safety concern. Closed-loop seals are CZPT alternatives to desiccant breathers because they prevent the entry of water. While these seals can’t keep the gearbox underwater, they isolate the gearbox from the atmosphere and are therefore vital for the safety of your equipment.

The most common material used for these seals is polymer rubber. Most are made from HBR, which stands for High-cis polybutadiene rubber. Other materials include Butadiene and FKM, which are known for their high-temperature performance. However, the disadvantage of these seals is that they are susceptible to shaft damage and degrade quickly in high temperatures. Therefore, you should always consider the type of seal before purchasing one.

If you plan to use agricultural gearboxes on a regular basis, you should consider getting a good quality one. You should look for a closed-loop seal on your gearbox to protect it against dirt and debris. A quality agricultural gearbox also has an easy-access design, which will make it easy to access and maintain. This will ensure its long-lasting performance and low-maintenance costs.

Agricultural equipment is frequently used to perform various tasks, such as sowing seeds, spreading fertilizer, digging holes, and more. This requires durable and effective sealing solutions to keep dirt out of the system and lubricants in. A close-loop seal helps to ensure that all these operations are performed at maximum efficiency. If you’re a farmer, closed-loop seals are the ideal solution for you.

Surface finish

The surface finish of an agricultural gearbox should be free from defects in the casting process and mechanical damage. The bearing hole in the shaft must be a minimum of 100 mm long and the distance between the bearing holes should be equal to the shaft length. The shaft should be free of any cracks or burrs. The ellipticity and centerline irregularity of the shaft must be less than 0.015 mm. Likewise, the diameter of the shaft, hole spacing and bearing hole relationship should be at least 20 mm.

In recent studies, researchers have investigated the efficiency of different surfaces on the same materials. They found that surface roughness affects gearbox efficiency. Kahraman et al. reported that superfinishing the gears and reducing surface roughness improved efficiency. In addition, Andersson et al. investigated the impact of different assembly processes on the gearbox’ surface roughness. The results of their studies are presented in Table I.

The quality of the surface finish of an agricultural gearbox depends on the materials used. A typical example is wrought steel gear. The die inserts for a forged gear were made of H11 or H13 tool steel. This material softens over time and has a limited life span. An improved alternative was Alloy 718. This alloy has a high temperature range and is suitable for high rotational speeds.

A good surface finish is vital for the health and safety of an agricultural gearbox. It protects the entire food chain and is necessary for agricultural production. The heightened demand for food will cause increased wear and tear on farm machinery. Moreover, a damaged gear will cost the farmer a lot of money. Therefore, it is crucial for farmers to invest in a high-quality agricultural gearbox to avoid such costly downtimes.

Shaft arrangement

An agricultural gearbox has two main stages, the first of which is the reduction stage. The reduction stage contains the pinion, a series of gears, and the first reduction stage. A second stage is connected to the first reduction stage via a mechanical clutch. This gearbox typically consists of three stages. The first reduction stage is also known as the low gear “L”. The first reduction stage provides four forward gearing ratios, while the second stage has three forward gearing ratios. A conventional agricultural gearbox also incorporates a mechanical clutch.

The second stage is a speed change gearbox. It has an input and output shaft. The input shaft is rotatably mounted in the casing and extends through the tractor’s interior. The shaft extends to the rear of the tractor, where the driven part of the joint 26 is keyed onto. The rear end portion of the shaft projects into the back axle casing 15, where it is connected to the first transmission shaft 34. The gearbox then serves to drive the power take-off shaft 36.

Newer types of tractors have larger shafts to support higher power applications. Type 3 tractors have a larger shaft with 20 splines while Type 2 tractors have a smaller shaft. The Type 2 is often referred to as the small 1000. When viewed from inside the tractor cab, Type 3 and Type 2 are rotated counterclockwise. If you are unfamiliar with agricultural gearboxes, here are some basic terms.

Shaft arrangement is important in choosing the right gearing system for agricultural machinery. There are a few differences between these arrangements. The first type has a higher gear ratio, while the second has lower. In terms of speed, the shaft arrangement of an agricultural gearbox reflects the speed of the machinery. The higher the speed of the gear, the higher the output speed. So, when choosing a gearbox, keep this in mind.

Cost

Purchasing an agricultural gearbox may be a costly process, but the benefits outweigh the price. Agricultural gearboxes are vital to the food cycle. When a gear breaks down, farmers will face significant losses. Additionally, agricultural applications use a high-quality gearbox to minimize equipment wear and tear. Ultimately, a high-quality gearbox will reduce the cost of production while extending the lifespan of the agricultural machinery.

Many countries trade in Agriculture Gearbox with India, and many of these suppliers are located in India. Using a marketplace to buy from Indian suppliers offers several advantages. Among the many factors to consider when choosing an Agriculture Gearbox supplier are quality, price, reliability, and past trade history. Through a marketplace like CZPT, you can obtain 360-degree information on Indian Agriculture Gearbox suppliers. In this way, you can choose a vendor with whom you do business.

CZPT Gearbox Company is a leading manufacturer of high-quality agricultural gearboxes. Their experienced engineers can reverse-engineer an existing design for a custom-made gearbox for your needs. Whether you need a smaller or larger gearbox for an agricultural application, CZPT Gearbox Company is your partner. A line of high-quality agricultural gearboxes from CZPT Gearbox Company will help you maximize the performance of your farm machinery. They will transfer rotational power from the input shaft to the output shafts, allowing for a change in speed, direction, and rotation.

editor by czh 2023-01-29

China Good quality BAFFERO K SERIES RIGHT ANGLE TYPE HELICAL BEVEL GEARBOX GEAR MOTOR GEARED MOTOR Speed reducer WITH HOLLOW SHAFT with Free Design Custom

Warranty: 12 months

Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Retail, Food Shop, Construction works , Energy & Mining, Food & Beverage Shops

Customized support: OEM, ODM

Gearing Arrangement: helical bevel

Output Torque: Up to 50000

Input Speed: 1500 r/min

Output Speed: 0.1-270 r/min

Material of gear: 20CrMnTi

Material of Shaft: 42CrMo

Material of housing: Cast Iron

Gear precision: DIN6

Gear Hardness: HRC58~62

Oil Seal: NAK Brand NBR material

Bearing: NSK, HRB ,C&U , Factory Propshaft Center Bearing Drive Shaft Support For CZPT Hilux For Lexus CZPT ,ZWZ

Heat treatment: Carburizing and Quenching

Ratio: 5~10000

Output shaft option: Solid and Hollow shaft

Certification: CE, ISO9001

Packaging Details: Standard export plywood case with plastic bag inside

Port: ZheJiang / HangZhou

Products Description Company Profile Workshop & Proessing procedure Certifications Why Us Strictly Quality Control bring Outstand Gearbox products 1: 100% testing for all the gears and Gear shaft and cast Iron Housing 2: 100% Running Test before delivery (Include Oil leak ,Noise and Vibration test3: 100% Appearance checking before packing Strong Production Capability & Advanced equipment & Faster delivery1: More than 150 professional workers & 40000 Squre meter factory base2: Imported Grinding machines(REISHAUER) ,ensure all gears we make are DIN 6 same as .3: Fast delivery (Spare part stock for all series gearboxes)4: 29 years experience since 1993 5: Customized gearbox according to client’s requrement Exhibition Application FAQ 1. How to choose a gearbox which meets our requirement?You can refer to our catalogue to choose the gearbox or we can help to choose when you providethe technical information of required output torque, output speed and motor parameter etc.2. What information shall we give before placing a purchase order?a) Type of the gearbox, ratio, Yuanlang MOTOR wheelchair motor input and output type, input flange, mounting position, and motor information ,etc.b) Housing color.c) Purchase quantity.d) Other special requirements.3. What industries are your gearboxes being used?Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry,escalator,automatic storage equipment, metallurgy, tabacco, Excellent performance injection pom plastic bushings custom Derlin bushing environmental protection, logistics and etc.4. Do you sell motors?We have stable motor suppliers who have been coperating with us for a long-time. They can provide motorswith high quality.

What Is a Gearbox?

There are several factors to consider when choosing a gearbox. Backlash, for example, is a consideration, as it is the angle at which the output shaft can rotate without the input shaft moving. While this isn’t necessary in applications without load reversals, it is important for precision applications involving load reversals. Examples of these applications include automation and robotics. If backlash is a concern, you may want to look at other factors, such as the number of teeth in each gear.

Function of a gearbox

A gearbox is a mechanical unit that consists of a chain or set of gears. The gears are mounted on a shaft and are supported by rolling element bearings. These devices alter the speed or torque of the machine they are used in. Gearboxes can be used for a wide variety of applications. Here are some examples of how gearboxes function. Read on to discover more about the gears that make up a gearbox.

Regardless of the type of transmission, most gearboxes are equipped with a secondary gear and a primary one. While the gear ratios are the same for both the primary and secondary transmission, the gearboxes may differ in size and efficiency. High-performance racing cars typically employ a gearbox with two green and one blue gear. Gearboxes are often mounted in the front or rear of the engine.

The primary function of a gearbox is to transfer torque from one shaft to another. The ratio of the driving gear’s teeth to the receiving member determines how much torque is transmitted. A large gear ratio will cause the main shaft to revolve at a slower speed and have a high torque compared to its counter shaft. Conversely, a low gear ratio will allow the vehicle to turn at a lower speed and produce a lower torque.

A conventional gearbox has input and output gears. The countershaft is connected to a universal shaft. The input and output gears are arranged to match the speed and torque of each other. The gear ratio determines how fast a car can go and how much torque it can generate. Most conventional transmissions use four gear ratios, with one reverse gear. Some have two shafts and three inputs. However, if the gear ratios are high, the engine will experience a loss of torque.

In the study of gearbox performance, a large amount of data has been collected. A highly ambitious segmentation process has yielded nearly 20,000 feature vectors. These results are the most detailed and comprehensive of all the available data. This research has a dual curse – the first is the large volume of data collected for the purpose of characterization, while the second is the high dimensionality. The latter is a complication that arises when the experimental gearbox is not designed to perform well.

Bzvacklash

The main function of a gearhead is to multiply a moment of force and create a mechanical advantage. However, backlash can cause a variety of issues for the system, including impaired positioning accuracy and lowered overall performance. A zero backlash gearbox can eliminate motion losses caused by backlash and improve overall system performance. Here are some common problems associated with backlash in gearheads and how to fix them. After you understand how to fix gearbox backlash, you’ll be able to design a machine that meets your requirements.

To reduce gearbox backlash, many designers try to decrease the center distance of the gears. This eliminates space for lubrication and promotes excessive tooth mesh, which leads to premature mesh failure. To minimize gearbox backlash, a gear manufacturer may separate the two parts of the gear and adjust the mesh center distance between them. To do this, rotate one gear with respect to the fixed gear, while adjusting the other gear’s effective tooth thickness.

Several manufacturing processes may introduce errors, and reducing tooth thickness will minimize this error. Gears with bevel teeth are a prime example of this. This type of gear features a small number of teeth in comparison to its mating gear. In addition to reducing tooth thickness, bevel gears also reduce backlash. While bevel gears have fewer teeth than their mating gear, all of their backlash allowance is applied to the larger gear.

A gear’s backlash can affect the efficiency of a gearbox. In an ideal gear, the backlash is zero. But if there is too much, backlash can cause damage to the gears and cause it to malfunction. Therefore, the goal of gearbox backlash is to minimize this problem. However, this may require the use of a micrometer. To determine how much gearbox backlash you need, you can use a dial gauge or feeler gauge.

If you’ve been looking for a way to reduce backlash, a gearbox’s backlash may be the answer. However, backlash is not a revolt against the manufacturer. It is an error in motion that occurs naturally in gear systems that change direction. If it is left unaccounted for, it can lead to major gear degradation and even compromise the entire system. In this article, we’ll explain how backlash affects gears and how it affects the performance of a gearbox.

Design

The design of gearboxes consists of a variety of factors, including the type of material used, power requirements, speed and reduction ratio, and the application for which the unit is intended. The process of designing a gearbox usually begins with a description of the machine or gearbox and its intended use. Other key parameters to consider during gearbox design include the size and weight of the gear, its overall gear ratio and number of reductions, as well as the lubrication methods used.

During the design process, the customer and supplier will participate in various design reviews. These include concept or initial design review, manufacturing design validation, critical design review, and final design review. The customer may also initiate the process by initiating a DFMEA. After receiving the initial design approval, the design will go through several iterations before the finalized design is frozen. In some cases, the customer will require a DFMEA of the gearbox.

The speed increaser gearboxes also require special design considerations. These gearboxes typically operate at high speeds, causing problems with gear dynamics. Furthermore, the high speeds of the unit increase frictional and drag forces. A proper design of this component should minimize the effect of these forces. To solve these problems, a gearbox should incorporate a brake system. In some cases, an external force may also increase frictional forces.

Various types of gear arrangements are used in gearboxes. The design of the teeth of the gears plays a significant role in defining the type of gear arrangement in the gearbox. Spur gear is an example of a gear arrangement, which has teeth that run parallel to the axis of rotation. These gears offer high gear ratios and are often used in multiple stages. So, it is possible to create a gearbox that meets the needs of your application.

The design of gearboxes is the most complex process in the engineering process. These complex devices are made of multiple types of gears and are mounted on shafts. They are supported by rolling element bearings and are used for a variety of applications. In general, a gearbox is used to reduce speed and torque and change direction. Gearboxes are commonly used in motor vehicles, but can also be found in pedal bicycles and fixed machines.

Manufacturers

There are several major segments in the gearbox market, including industrial, mining, and automotive. Gearbox manufacturers are required to understand the application and user industries to design a gearbox that meets their specific requirements. Basic knowledge of metallurgy is necessary. Multinational companies also provide gearbox solutions for the power generation industry, shipping industry, and automotive industries. To make their products more competitive, they need to focus on product innovation, geographical expansion, and customer retention.

The CZPT Group started as a small company in 1976. Since then, it has become a global reference in mechanical transmissions. Its production range includes gears, reduction gearboxes, and geared motors. The company was the first in Italy to achieve ISO certification, and it continues to grow into one of the world’s leading manufacturers of production gearboxes. As the industry evolves, CZPT focuses on research and development to create better products.

The agriculture industry uses gearboxes to implement a variety of processes. They are used in tractors, pumps, and agricultural machinery. The automotive industry uses gears in automobiles, but they are also found in mining and tea processing machinery. Industrial gearboxes also play an important role in feed and speed drives. The gearbox industry has a diverse portfolio of manufacturers and suppliers. Here are some examples of gearboxes:

Gearboxes are complex pieces of equipment. They must be used properly to optimize efficiency and extend their lifespan. Manufacturers employ advanced technology and strict quality control processes to ensure their products meet the highest standards. In addition to manufacturing precision and reliability, gearbox manufacturers ensure that their products are safe for use in the production of industrial machinery. They are also used in office machines and medical equipment. However, the automotive gearbox market is becoming increasingly competitive.

in Campo Grande Brazil sales price shop near me near me shop factory supplier Spiral Bevel Helical Gearbox Box 90 Degree High-Quality Transmission Right Angle Speed Reducer Alloy Steel Stainless Induction Straight Spiral Bevel Gearboxes manufacturer best Cost Custom Cheap wholesaler

Every approach, each part, each purpose in EPG is demanded to be carried out one particular action pursuing another, cautiously and cautiously, from content assortment, reformation to manufacturing accessories, from parts heat remedy to automatic assembly, from high quality management to item inspection and tests and from order working to soon after product sales provider. “We are often serving our customers with our best items.” Full use has been manufactured of all types of innovative tactics and technologies to get to excelsior manufacturing.

Spiral EPTTl Helical EPTT Box 90 Degree Large-EPTT EPTT RigEPTT Angle Velocity EPTT Alloy Steel Stainless Induction StraigEPTT Spiral EPTTl EPTTes

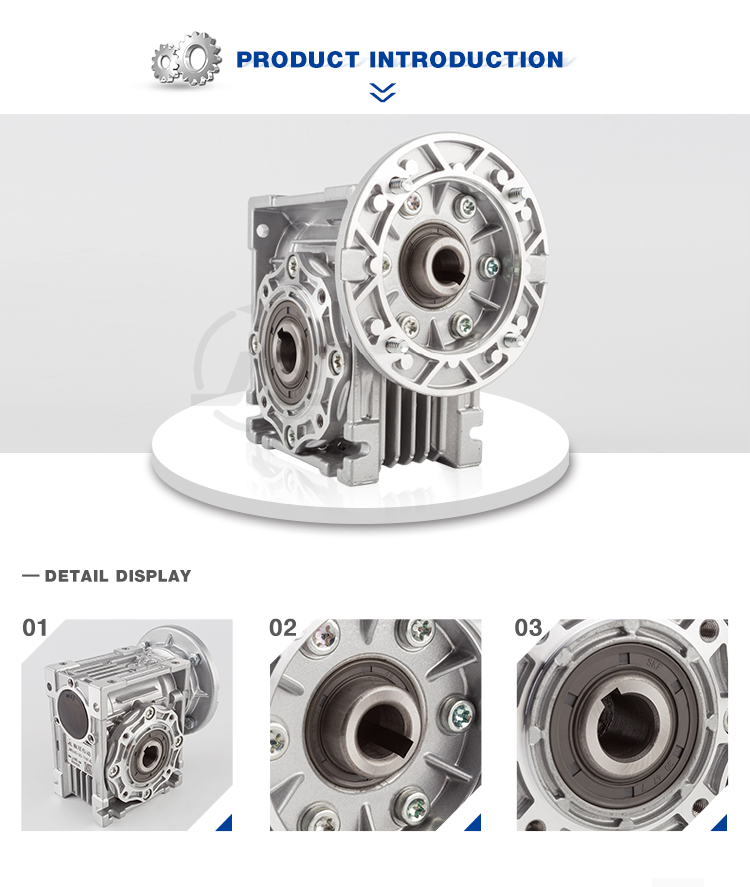

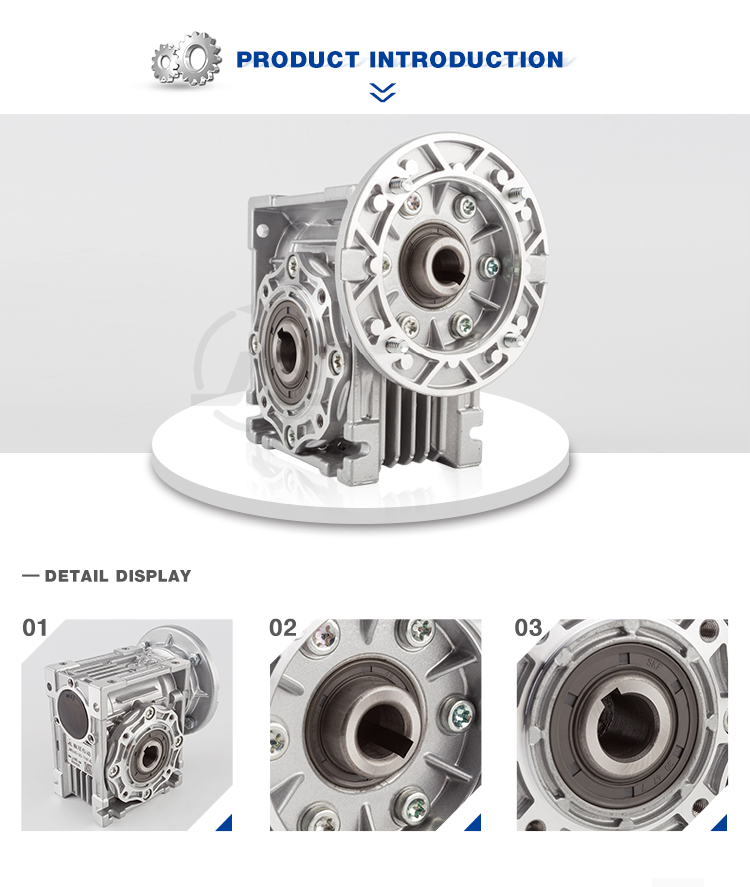

Best China manufacturer & factory Buy in Beirut Lebanon small right angle bevel 10 to 1 worm gear drive reduction reconditioned automatic gearbox With high quality best price

FURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS ACCORDING TO CUSTOMERS’ DRAWINGS.

Overview

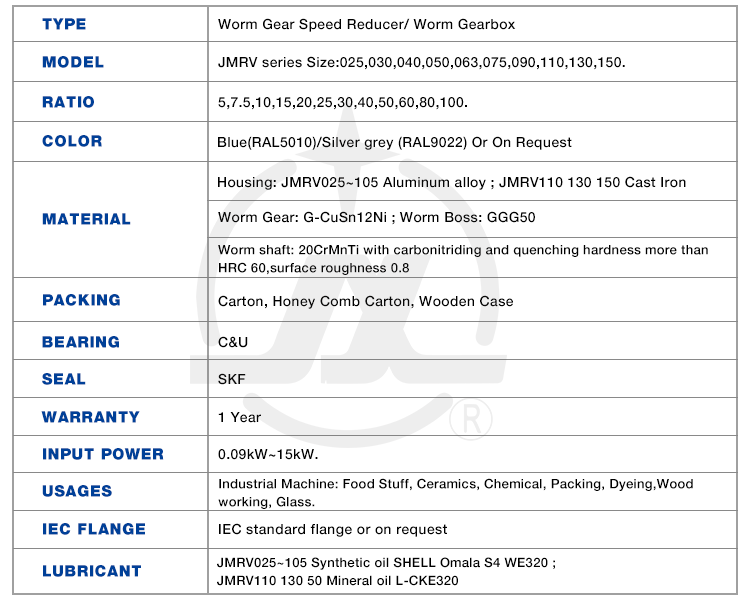

Quick Details

- Applicable Industries:

-

Construction works

- Gearing Arrangement:

-

worm

- Output Torque:

-

15~1700Nm

- Input Speed:

-

500~2800/min

- Output Speed:

-

5~560/min

- Brand Name:

-

OEM

- Product name:

-

worm gear drive reduction reconditioned automatic gearbox

- Application:

-

Food Stuff, Ceramics, Chemical, Packing, Dyeing,Wood working, Glass.

- Color:

-

Blue(RAL5010)/Silver grey (RAL9022) Or On Request

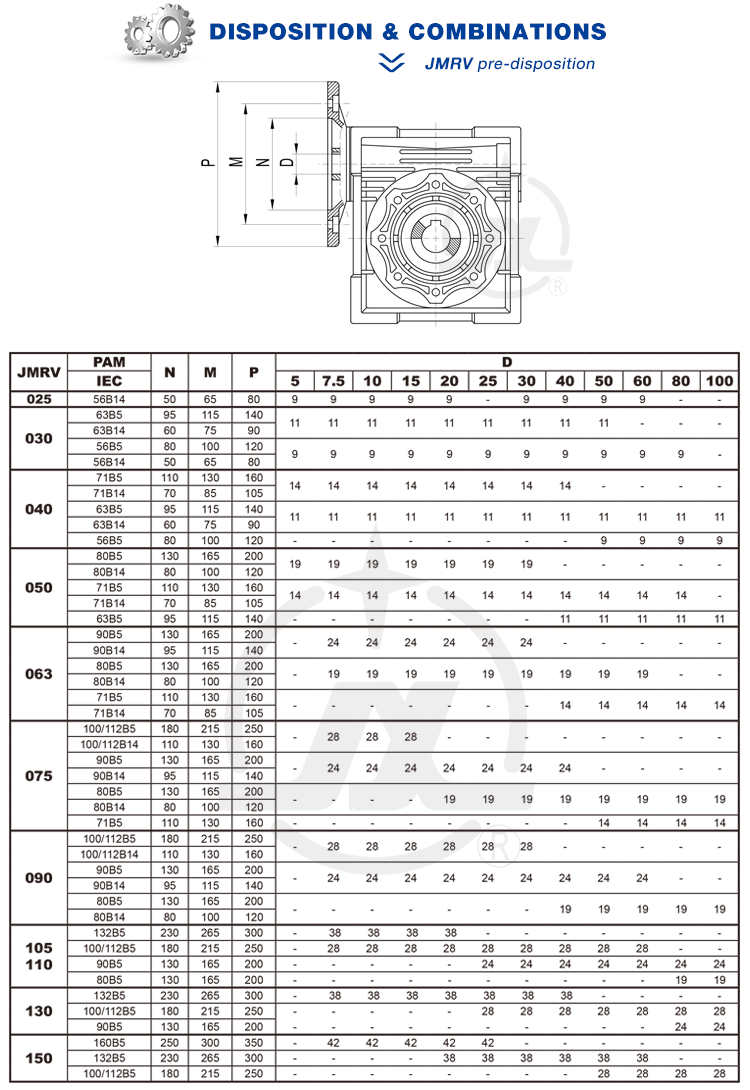

- Ratio:

-

5,7.5,10,15,20,25,30,40,50,60,80,100.

- Warranty:

-

1 Year

Supply Ability

- Supply Ability:

- 36000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Transparent box packaging, or color box packaging, it also can be customized.

- Port

- Ningbo/Shanghai

A seal-journal surface that features an inverted shot-peened texture, with raised (rather than indented) spherical lobes and corresponding valleys in between, better supports hydrodynamic lubrication. EPT developed a process that compresses seal journals between burnishing dies that have been peened to create random spherical depressions. This leaves an “orange peel” texture on the journal surface, typically with a 20 to 40-m in. surface roughness.

Online Customization

Buy small right angle bevel 10 to 1 worm gear drive reduction reconditioned automatic gearbox

Q1.How to choose a automatic gearbox which meets our requirement?

A1: You can refer to our catalogue to choose the gearbox or we can help to choose when you provide

the technical information of output torque, output speed and motor Main products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc.parameter etc.

Q2.How is your price? Can you offer any discount?

A2: We will give the best price we can base on your needs and the quantities.

Q3.Do you offer any visiting?

A3: Yes! We sincerely invite you to visit us! We can pick you from airport, railway station and so on.

Also, we can arrange housing for you. Please let us know in advanced.

Q4.When is the best time to contact you?

A4: You can contact us by email any time, we will reply you as soon as possible.

Q5.How long will it take for the lead time?

A5: For our standard model, please refer to the different product pages to check the lead time.

For the OEM/ODM products, please contact us for further information.

Once the PTO has begun to power the attachment, steadily increase the throttle until you reach the operating speed. The typical running RPM (revolutions per minute) for a tractor mounted PTO is 540 RPM, although there are tractor models that rev higher. Always refer to your particular tractor model for instructions prior to first-time use.

bevel Manufacturing plant gear speed reducer right angle bevel gearbox bevel gearbox for agricultural machinery multi-speed 90-degree gearboxes

If you are fascinated in any of our items or would like to examine a potential buy, remember to come to feel totally free to get in touch with us. EPG was awarded with “renowned product of Zhejiang Province” and “renowned brand name of Zhejiang Province”. guarantees the balance and regularity of the key operate of elements.

Overview

Swift Details

- Applicable Industries:

-

Hotels, Garment Outlets, Constructing Material Retailers, Manufacturing Plant, Equipment Fix Shops, Foods amp Beverage Factory, Farms, Restaurant, Property Use, Retail, Foods Store, Printing Outlets, Development functions nbsp, Strength amp Mining, Foodstuff amp Beverage Shops, Advertising Business

- Location of Origin:Zhejiang, China

- Brand Title:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

10~62800N.m

- Enter Velocity:

-

1450/960rpm

- Output Speed:

-

14-280rpm

- Ratio:

-

5.36~197.37

- Certification:

-

ISO9001-2008

- Mount Situation:

-

Foot Mounted

- Bearing:

-

LYC, HRB,ZWZ,SKF,NSK

Packaging Shipping

- Offering Models:

- Single item

- One bundle measurement: nbsp

- 50X50X60 cm

- Single gross excess weight:

- 57.000 kg

- Deal Type:

- Picket packing containers , Cantons packed in one pallet

-

Guide Time

: -

Amount(Units) one – 1 >1 Est. Time(times) ten To be negotiated

On the internet Customization

Product Description

nbsp

SLK sequence gearbox is one kind of Helical Bevel variety gearbox , Higher-stainless solid iron scenario . ,it is designed dependent on modularization , which provide a lot of distinction varieties of mixtures ,mounting types ,and composition types .The detail classification of ratio can fulfill different of operating condition .Large Transmission effectiveness ,Reduced strength intake, superior efficiency . The difficult tooth surface area gear use the higher quality alloy steel , the approach of carburizing and quenching, grinding ,which give it stick to people : Stable transmission , low sounds and temperature ,substantial loading ,long functioning daily life. which commonly use for industry products of metallurgy ,Constructing Material , Chemical , Mining , Oil, Transportation , Papermaking , Sugar making , engineering Machines ,and so forth

nbsp

Specs:

1) Output velocity: .six~1,028r/min

two) Output torque: up to 21700N.m

3) Motor power: .twelve~200kW

4) Mounted form: foot-mounted and flange-mounted mounting

nbsp

|

Merchandise Identify |

SLK Collection nbspRigid Tooth nbsphelical bevel reducer nbsp |

|

Equipment Content |

20CrMnTi nbsp |

|

Situation Content |

HT250 |

|

Shaft Content nbsp |

20CrMnTi |

|

Equipment Processing |

Grinding finish by HOFLER Grinding Machines |

|

Colour nbsp |

Custom-made |

|

Sounds Examination |

65~70dB |

|

Effectiveness |

ninety four%~98% (depends on the transmission stage) nbsp |

|

Lubricating oil |

Shell Omala synthetic oil or mineral oil , or comparable brand name nbsp |

|

Heat therapy |

tempering, cementiting, quenching,and so forth. |

|

Manufacturer of bearings |

C ampU bearing, ZWZ,LYC, HRB, SKF,NSK and so on |

|

Brand of oil seal |

NAK or other manufacturer |

|

Temp. rise (MAX) |

40 deg |

|

Temp. rise (Oil)(MAX) |

50 deg |

|

Vibration |

ep20 microm |

nbsp

nbsp

nbsp

Ever-electricity

nbsp

Packing Specifics: Normal carton/Pallet/Common picket scenario

Supply Details : 7-twenty operating days on payment

nbsp

nbsp

Organization Information

About us

Set up in 1985, SANLIAN nbspTRANSMISSION nbspMACHINERY nbspCO., nbspLTD is a large and new technological innovation business partaking nbspin study, nbspdevelop nbspand manufacture nbspfor reducer amp pace variator, one particular of the director member of China Reducer Association of China General Equipment.

It nbspcovers far more than nbsp40,000 sq. meters, has far more than four hundred workers , twenty% of whom are professionals, outfitted with a lot more than three hundred sets the most innovative exact numerical control nbspequipment, which includes German HOFLER forming nbspgear grinding equipment to enhance top quality.

set up far more than 30 national income branches to serve our consumers in time and totally.

Our merchandise also nbspexported to a lot more than 30 nations nbspmain nbspin Europe, Asia nbsp nbspAmerica, nbspand Africa, with higher reputation.

nbsp

Related Merchandise

Get in touch with us

other collection solution

| Precision Planetary gearbox | Robot RV gearbox speed reducer |

| Personalized manufactured Non-common Gearbox | UDL Sequence Variator |

| PYZ Sequence Helical Tooth Shaft Mounted Reducer | 8000 Sequence Cycloidal Reducer |

| SLT Collection nbsp Spiral Bevel Gearbox | SLSWL Sequence Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Series Higher Energy Reducer |

| NMRV Series Worm Reducer | BKM Sequence Helical-hypoid Reducer |

| SLRC Collection Helical Reducer | SLSMR Collection Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer | nbsp |

nbsp

Make contact with

nbsp

nbsp nbsp nbsp nbsp nbsp

nbsp

nbsp

nbsp

nbsp

FAQ

one.Payment Expression: TT, L/C

two.Shipping and delivery time: about nbsp thirty days from obtain payment. nbsp

three.We take personalized merchandise as for every your special requirement.

4.Suggestions for the Selection:Normally we can select a single equipment which is suitable for you with some informations from you,such as ratio/motor velocity/mounting dimension/ out torque and many others. nbsp

five.If the minimum purchase quantity is in excessive of $10000, there are preferential.

Q1: What details must I notify you to confirm the solution?

A:Design/Dimension, Transmission Ratio, Shaft instructions amp Get amount.

Q2: What can i do if I never know which one I need?

A:Dont fret, Send as a lot information as you can, our group will support you discover the appropriate one you are hunting for.

Q3: What is your product warranty time period?

A:We offer you one particular 12 months warranty since the vessel departure day left China.

nbsp

Q4: Are you buying and selling business or manufacturer ?

A: We are factory.

nbsp

Q5: How long is your supply time?

A: Normally it is five-10 times if the merchandise are in stock. or it is fifteen-twenty times if the goods are not in inventory, it is according to quantity.

nbsp

Q6: Do you give samples ? is it totally free or added ?

A: Yes, we could provide the sample for totally free cost but do not spend the expense of freight.

nbsp

Q7: What is your terms of payment ?

A: Payment lt=1000USD, 100% in progress. Payment gt=1000USD, 30% T/T in progress ,harmony ahead of shippment.

nbsp

If you have another query, pls feel totally free to speak to us as underneath: