Product Description

Company Profile

HangZhou Xihu (West Lake) Dis. East Port Gear Manufacturing factory is located in Zhoujia Industrial Zone, CHINAMFG Town, HangZhou, 3km away from Xihu (West Lake) Dis.qian Lake. It focuses on precision gear research, development, production and sales. The factory has obtained ISO9001: 2015 certificate, IATF16949:2016. The main export markets were North America, South America and Europe. Products can be customized and mainly includes: New Energy Motor Shaft, Oil Pump Gear, Agricultural Machinery Gear, Transmission Gear, Electric Vehicle gear, etc. We are sincerely willing to cooperate with enterprises from all over the world.

Equipment And Main Products

Certifications

FAQ

Q1:How is the quality of your product?

A:Our product has reliable quality, high wear life

Q2:Customization process/work flow?

Advisory – Material selection – 2D/3D Drawing – Quotation – Payment – Production – Quality Control – Package – Delivery

Q3: What is your terms of packing?

A:Generally, we pack our goods in wooden cases, If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q4:Price?

A:We will offer competitive price after receiving your drawing

Q5:What is your terms of payment?

A:30% T/T advanced, 70% T/T before shipping

Q6:What is your terms of delivery?

A: FOB

Q7:What drawing software does your company use?

A:CAXA

Q8:Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q9:How about your delivery time?

A:Product can often be delivered within 40-90 days

Q10:Sample?

A:We offer paid sample.If you have sample requirements, please feel free to contact us at any time

Q11:What logistics packaging does your company use?

A:Express for urgent orders. UPS, FedEx, DHL, TNT, EMS.

Q12:Application range?

A:Automotive, medical, automation, agricultural, marine, etc.

Q13: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Parameter specifications

| Certification | Shipment | Quality | material | Company System Certification |

| IATF16949 | in time | high | steel | ISO9001 |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample customized version

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Case Studies: Successful Implementations of Agricultural Gearboxes

Several case studies highlight the successful integration of agricultural gearboxes in farming machinery:

- Case Study 1: Tractor Versatility

A farm in the Midwest implemented tractors equipped with adjustable gearboxes. The gearboxes allowed the tractors to seamlessly switch between plowing, planting, and harvesting tasks. The ability to customize speed and torque ratios improved efficiency and reduced the need for multiple machines.

- Case Study 2: Orchard Management

An orchard in California utilized specialized gearboxes in its mechanized harvesters. These gearboxes facilitated controlled movement and precise positioning of the harvesters among trees. The adaptability of the gearboxes enabled the harvesters to navigate the orchard’s uneven terrain while minimizing damage to trees and fruit.

- Case Study 3: Precision Planting

A farm in Europe integrated precision planting machinery with gearboxes that offered adjustable gear ratios. This allowed for precise control over seed placement and depth. The gearboxes played a vital role in achieving uniform crop emergence and optimizing seed-to-soil contact.

- Case Study 4: Multi-Tasking Implements

A farming cooperative in Australia utilized multi-tasking implements equipped with versatile gearboxes. These implements could seamlessly switch between tasks such as plowing, harrowing, and fertilizing. The gearboxes’ ability to manage torque and speed ratios ensured optimal performance across various tasks.

- Case Study 5: Soil Conservation

A farm in Africa adopted gearboxes in its soil conservation practices. By attaching specialized implements with adjustable gearboxes to their tractors, the farm effectively controlled soil erosion and improved water infiltration rates. The gearboxes allowed for precise adjustments based on soil type and slope.

These case studies illustrate the impactful role of agricultural gearboxes in enhancing efficiency, versatility, and productivity across a spectrum of farming applications.

Potential Challenges in Maintenance and Repairs of Agricultural Gearboxes

Maintenance and repairs of gearboxes in agriculture can pose several challenges:

- Harsh Environments: Agricultural machinery operates in challenging environments with exposure to dirt, debris, moisture, and varying temperatures. These conditions can accelerate wear and corrosion, necessitating frequent maintenance.

- Heavy Workloads: Gearboxes in farming equipment often handle heavy workloads, leading to increased stress on components. This can result in faster wear and tear, requiring more frequent inspections and part replacements.

- Accessibility: Some gearboxes are located in hard-to-reach areas of machinery. This makes regular maintenance and repairs more challenging, as technicians may need specialized tools and equipment to access and service the gearboxes.

- Specialized Knowledge: Proper maintenance of agricultural gearboxes requires specialized knowledge and skills. Inadequate understanding of gearbox mechanics and maintenance practices can lead to improper repairs, reducing the gearbox’s lifespan and efficiency.

- Costs: Repairing or replacing gearbox components can be costly, especially for heavy-duty agricultural machinery. Farmers need to consider both the direct costs of parts and labor, as well as potential downtime during repair processes.

- Downtime: The downtime required for gearbox maintenance or repairs can impact farming operations, especially during critical planting or harvesting seasons. Efficient scheduling and backup equipment can help mitigate this challenge.

- Availability of Parts: Obtaining replacement parts for older or less common gearbox models can be challenging. Farmers may need to source parts from specialized suppliers, leading to potential delays in repairs.

Addressing these challenges requires proactive maintenance planning, regular inspections, proper training of maintenance personnel, and sourcing spare parts in advance.

Benefits of Using High-Quality Gearboxes in Agricultural Machinery

Utilizing high-quality gearboxes in agricultural machinery offers several advantages that contribute to enhanced performance, durability, and overall operational efficiency. Here are the key benefits:

- Reliability and Durability: High-quality gearboxes are built to withstand the demanding conditions of agricultural operations. They are constructed using durable materials, precise manufacturing techniques, and stringent quality control measures, ensuring a longer lifespan and reduced downtime due to breakdowns.

- Optimal Power Transmission: High-quality gearboxes facilitate efficient power transmission from the tractor’s engine to various implements. They minimize power losses through well-designed gear profiles, accurate alignments, and minimal friction, allowing for more effective utilization of available power.

- Smooth Operation: Gearboxes manufactured to high standards provide smooth and consistent operation. They reduce vibrations, noise, and unnecessary wear, creating a comfortable working environment for the operator and reducing stress on the machinery.

- Precision and Accuracy: Quality gearboxes offer precise control over speed, torque, and direction changes. This precision ensures accurate implementation of farming tasks, such as seeding, planting, and harvesting, leading to better yield outcomes.

- Increased Efficiency: High-quality gearboxes minimize energy losses due to friction and inefficient gear meshing. This improved efficiency results in better fuel economy and optimized power utilization, reducing operating costs for the farmer.

- Compatibility and Adaptability: Top-tier gearboxes are designed to be compatible with a range of agricultural implements and machinery. Their adaptability allows farmers to switch between different tasks without the need for frequent adjustments or component changes.

- Reduced Maintenance Costs: Quality gearboxes require less frequent maintenance and repair. Their robust construction and precision engineering result in fewer breakdowns and extended maintenance intervals, saving both time and money.

- Enhanced Safety: Reliable gearboxes contribute to safer operations by preventing sudden failures that could lead to accidents. The smooth operation and predictable performance of high-quality gearboxes reduce the risk of mishaps during agricultural tasks.

Overall, investing in high-quality gearboxes for agricultural machinery ensures improved reliability, smoother operation, higher precision, increased efficiency, and reduced maintenance costs. These benefits ultimately contribute to enhanced productivity and better outcomes for farmers and agricultural operations.

editor by CX 2024-01-03

China OEM Agricultural Machinery Uses Power Transmission Shafts, Transmission Shafts, Factory Steel Precision Transmission, CNC Machining Gearbox, Agricultural Machinery9 agricultural pto gearbox

Product Description

Company Profile

HangZhou Xihu (West Lake) Dis. East Port Gear Manufacturing factory is located in Zhoujia Industrial Zone, CZPT Town, HangZhou, 3km away from Xihu (West Lake) Dis.qian Lake. It focuses on precision gear research, development, production and sales. The factory has obtained ISO9001: 2015 certificate, IATF16949:2016. The main export markets were North America, South America and Europe. Products can be customized and mainly includes: New Energy Motor Shaft, Oil Pump Gear, Agricultural Machinery Gear, Transmission Gear, Electric Vehicle gear, etc. We are sincerely willing to cooperate with enterprises from all over the world.

Equipment And Main Products

Certifications

FAQ

Q1:How is the quality of your product?

A:Our product has reliable quality, high wear life

Q2:Customization process/work flow?

Advisory – Material selection – 2D/3D Drawing – Quotation – Payment – Production – Quality Control – Package – Delivery

Q3: What is your terms of packing?

A:Generally, we pack our goods in wooden cases, If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q4:Price?

A:We will offer competitive price after receiving your drawing

Q5:What is your terms of payment?

A:30% T/T advanced, 70% T/T before shipping

Q6:What is your terms of delivery?

A: FOB

Q7:What drawing software does your company use?

A:CAXA

Q8:Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q9:How about your delivery time?

A:Product can often be delivered within 40-90 days

Q10:Sample?

A:We offer paid sample.If you have sample requirements, please feel free to contact us at any time

Q11:What logistics packaging does your company use?

A:Express for urgent orders. UPS, FedEx, DHL, TNT, EMS.

Q12:Application range?

A:Automotive, medical, automation, agricultural, marine, etc.

Q13: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Parameter specifications

| Certification | Shipment | Quality | material | Company System Certification |

| IATF16949 | in time | high | steel | ISO9001 |

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample customized version

|

|---|

| Customization: |

Available

| Customized Request |

|---|

Choosing the Right Agricultural Gearbox

When buying an agricultural gearbox, there are a few things to consider. The quality of materials, functionality, and mechanism are crucial factors to durability. A durable device will ensure that you won’t have to keep replacing it. Here are some tips to help you select the right one. Let’s begin. Read on to learn more about the different features available in agricultural gearboxes. Listed below are a few of the most important factors to consider.

Bevel gearboxes

Agricultural gearboxes are essential to the entire food cycle. If your gears are not in good shape, you will be unable to meet the demand and you will suffer from heightened downtime. Fortunately, there are numerous quality bevel gearboxes available on the market today. In fact, the CZPT Gearbox Company supplies bevel gearboxes for agricultural applications. Here are some of the reasons you should choose the right one.

A bevel gearbox is a single-stage unit that interlocks bevelled edges on two gears to transfer torque and rotation. These gears can be either straight or helical. This type of gearbox is inexpensive to produce and operates quietly. It also has lower transmittable torque. Bevel gearboxes are often used as a low-cost alternative to hypoid gearboxes.

Agricultural bevel gearboxes are used in various applications, including hay balers, combine harvesters, seeders, and plows. These gears are well-suited for use with offset rotary fillers. They offer reduction ratios of up to 2.44 and cast iron cases. They are commonly known as “right-angle gearboxes” or “Parallel SHAFT gearboxes.”

Agricultural bevel gearboxes come in many sizes and ratios. In general, higher sizes are made of closed-grain cast-iron. Other materials, such as SG 500/7, are used for larger sizes. The main gear and each drive gear are mesh-mounted, and the shafts are designed to rotate in either direction. They have oil seals on the joints. The Spiral Bevel Gearbox is best suited for FG60 or FG75 motors.

The RINV-OP65 right-angle angular gearbox comes with an optional electronic or mechanical position indicator. Its angular design allows for changes in axis rotation, and provides smooth power transmission with minimal backlash. Premium gearmotors include hardened spiral bevel gears and stainless steel shafts for quiet operation. They are available in various ratios and shaft styles. If you want to choose one, make sure it is made to fit the needs of the machine.

Closed-loop seals

There are a number of reasons to install closed-loop seals in an agricultural gearbox. The first is the need to isolate the gearbox from the atmosphere, an important safety concern. Closed-loop seals are CZPT alternatives to desiccant breathers because they prevent the entry of water. While these seals can’t keep the gearbox underwater, they isolate the gearbox from the atmosphere and are therefore vital for the safety of your equipment.

The most common material used for these seals is polymer rubber. Most are made from HBR, which stands for High-cis polybutadiene rubber. Other materials include Butadiene and FKM, which are known for their high-temperature performance. However, the disadvantage of these seals is that they are susceptible to shaft damage and degrade quickly in high temperatures. Therefore, you should always consider the type of seal before purchasing one.

If you plan to use agricultural gearboxes on a regular basis, you should consider getting a good quality one. You should look for a closed-loop seal on your gearbox to protect it against dirt and debris. A quality agricultural gearbox also has an easy-access design, which will make it easy to access and maintain. This will ensure its long-lasting performance and low-maintenance costs.

Agricultural equipment is frequently used to perform various tasks, such as sowing seeds, spreading fertilizer, digging holes, and more. This requires durable and effective sealing solutions to keep dirt out of the system and lubricants in. A close-loop seal helps to ensure that all these operations are performed at maximum efficiency. If you’re a farmer, closed-loop seals are the ideal solution for you.

Surface finish

The surface finish of an agricultural gearbox should be free from defects in the casting process and mechanical damage. The bearing hole in the shaft must be a minimum of 100 mm long and the distance between the bearing holes should be equal to the shaft length. The shaft should be free of any cracks or burrs. The ellipticity and centerline irregularity of the shaft must be less than 0.015 mm. Likewise, the diameter of the shaft, hole spacing and bearing hole relationship should be at least 20 mm.

In recent studies, researchers have investigated the efficiency of different surfaces on the same materials. They found that surface roughness affects gearbox efficiency. Kahraman et al. reported that superfinishing the gears and reducing surface roughness improved efficiency. In addition, Andersson et al. investigated the impact of different assembly processes on the gearbox’ surface roughness. The results of their studies are presented in Table I.

The quality of the surface finish of an agricultural gearbox depends on the materials used. A typical example is wrought steel gear. The die inserts for a forged gear were made of H11 or H13 tool steel. This material softens over time and has a limited life span. An improved alternative was Alloy 718. This alloy has a high temperature range and is suitable for high rotational speeds.

A good surface finish is vital for the health and safety of an agricultural gearbox. It protects the entire food chain and is necessary for agricultural production. The heightened demand for food will cause increased wear and tear on farm machinery. Moreover, a damaged gear will cost the farmer a lot of money. Therefore, it is crucial for farmers to invest in a high-quality agricultural gearbox to avoid such costly downtimes.

Shaft arrangement

An agricultural gearbox has two main stages, the first of which is the reduction stage. The reduction stage contains the pinion, a series of gears, and the first reduction stage. A second stage is connected to the first reduction stage via a mechanical clutch. This gearbox typically consists of three stages. The first reduction stage is also known as the low gear “L”. The first reduction stage provides four forward gearing ratios, while the second stage has three forward gearing ratios. A conventional agricultural gearbox also incorporates a mechanical clutch.

The second stage is a speed change gearbox. It has an input and output shaft. The input shaft is rotatably mounted in the casing and extends through the tractor’s interior. The shaft extends to the rear of the tractor, where the driven part of the joint 26 is keyed onto. The rear end portion of the shaft projects into the back axle casing 15, where it is connected to the first transmission shaft 34. The gearbox then serves to drive the power take-off shaft 36.

Newer types of tractors have larger shafts to support higher power applications. Type 3 tractors have a larger shaft with 20 splines while Type 2 tractors have a smaller shaft. The Type 2 is often referred to as the small 1000. When viewed from inside the tractor cab, Type 3 and Type 2 are rotated counterclockwise. If you are unfamiliar with agricultural gearboxes, here are some basic terms.

Shaft arrangement is important in choosing the right gearing system for agricultural machinery. There are a few differences between these arrangements. The first type has a higher gear ratio, while the second has lower. In terms of speed, the shaft arrangement of an agricultural gearbox reflects the speed of the machinery. The higher the speed of the gear, the higher the output speed. So, when choosing a gearbox, keep this in mind.

Cost

Purchasing an agricultural gearbox may be a costly process, but the benefits outweigh the price. Agricultural gearboxes are vital to the food cycle. When a gear breaks down, farmers will face significant losses. Additionally, agricultural applications use a high-quality gearbox to minimize equipment wear and tear. Ultimately, a high-quality gearbox will reduce the cost of production while extending the lifespan of the agricultural machinery.

Many countries trade in Agriculture Gearbox with India, and many of these suppliers are located in India. Using a marketplace to buy from Indian suppliers offers several advantages. Among the many factors to consider when choosing an Agriculture Gearbox supplier are quality, price, reliability, and past trade history. Through a marketplace like CZPT, you can obtain 360-degree information on Indian Agriculture Gearbox suppliers. In this way, you can choose a vendor with whom you do business.

CZPT Gearbox Company is a leading manufacturer of high-quality agricultural gearboxes. Their experienced engineers can reverse-engineer an existing design for a custom-made gearbox for your needs. Whether you need a smaller or larger gearbox for an agricultural application, CZPT Gearbox Company is your partner. A line of high-quality agricultural gearboxes from CZPT Gearbox Company will help you maximize the performance of your farm machinery. They will transfer rotational power from the input shaft to the output shafts, allowing for a change in speed, direction, and rotation.

editor by CX 2023-06-12

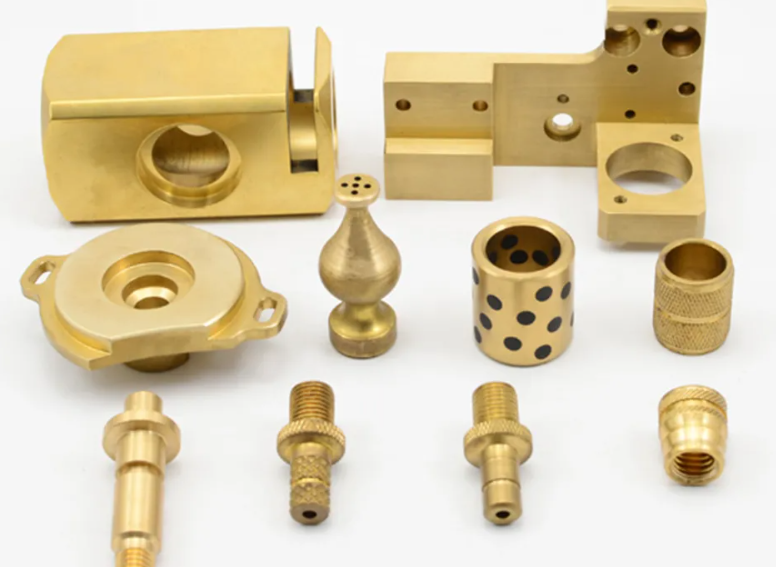

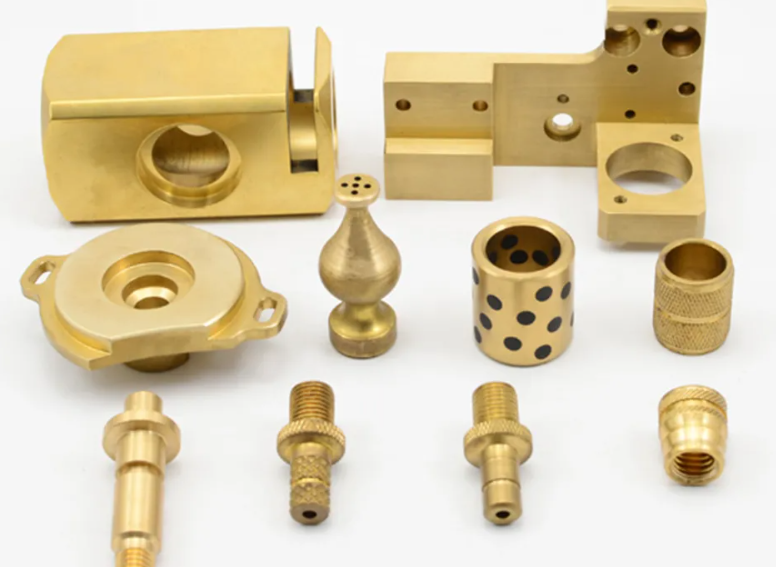

China Hot selling CNC Machining Milling Agricultural Machinery Spare Parts with high quality

Merchandise Description

Items demonstrate :

Package :

Our firm :

About Us :

Integrated precision CNC machining options supplier

As an OEM /ODM manufacturer ,high quality and service are our hallmark . Especially your project

Demands large precise and surface area treatment method .

Our companies is able of handling more substantial amount custom made factors in a range of

CNC machining. Milling ,turning ,die-casting ,sheet metallic stamping etc

These CNC deep processing products active in automotive ,telecommunication devices,

digital, industrial machinery , medical, aerospace ……..

We are constantly consumers reputable and dependable associate and supported

FAQ

Q: Are you buying and selling business or company ?

A: We are manufacturing unit.

Q: How lengthy is your supply time?

A: Generally it is ten-15 days . or it is fifteen-twenty times if the

quantity is greater

Q: Do you give samples ? is it free or additional ?

A: Sure, we could offer the sample for free cost but do not shell out the price of

express delivery fee

Q: What is your phrases of payment ?

A: Payment=1000USD, thirty% T/T in

advance ,stability just before shippment.

If you have yet another query, pls truly feel free to make contact with us as below:

Make contact with Details :

web:HangZhouderf

pls speak to us freely

Personalized Precision CNC Machining Turning & Milling areas Services

best top quality cnc machining milling alodine aluminium chassis with entrance panel

custom CNC machined aluminum tube amplifier alodine chassis parts

Aluminum Higher Specific Machining Parts CNC for Interaction

OEM personalized CNC metal components .custom leading quality OEM/ODM design plastics /metallic

cnc turning parts

Custom-made Higher precision Brass Bronze Copper CNC Turning Areas

Difficult Anodizing Aluminium CNC Turning Components

Personalized OEM CNC Turning Areas Metal Lathe elements For Mechanical

Carbon Steel /stainless steel CNC Precision Turning Parts

Customized Precision aluminum /stainless steel /brass CNC Milling Elements

Custom-made ODM/OEM CNC Milling Areas

CNC Machining milling Agricultural Equipment Spare Parts

| Product Description | |

| Products name : | OEM custom CNC metal parts .custom top quality OEM/ODM design plastics /metal cnc turning parts .Customized High precision Brass Bronze Copper CNC Turning Parts .Hard Anodizing Aluminium CNC Turning Parts.Customized OEM CNC Turning Parts Metal Lathe parts For Mechanical.Carbon Steel /stainless steel CNC Precision Turning Parts.Custom Precision aluminum /stainless steel /brass CNC Milling Parts.ODM/OEM CNC Milling Parts.CNC Machining milling Agricultural Machinery Spare Parts |

| Material : | Aluminum alloy 6061. 6063. 7075 .5082 and etc . steel alloy /stainless steel , titanium , brass/ copper , plastics and so on |

| Surface treatment : | painting , coating , oxide , anodized , powder coating , or according customer require |

| MOQ : | 10pcs |

| samples : | first will do samples send to customer test , after confirmed quality is ok , then do production |

| Package : | each parts will use foam pack , outer is wood box or pallet , strong package guarantee products no any damage ,injured during transportaion way. |

| Services : | customized , OEM/ODM service . machining service |

| Application : | automotive spare parts , motorcycle parts , machine , electronic spare parts etc |

| Market : | North American , european, middle east, african , Canada, Englad and so on |

| Product Description | |

| Products name : | OEM custom CNC metal parts .custom top quality OEM/ODM design plastics /metal cnc turning parts .Customized High precision Brass Bronze Copper CNC Turning Parts .Hard Anodizing Aluminium CNC Turning Parts.Customized OEM CNC Turning Parts Metal Lathe parts For Mechanical.Carbon Steel /stainless steel CNC Precision Turning Parts.Custom Precision aluminum /stainless steel /brass CNC Milling Parts.ODM/OEM CNC Milling Parts.CNC Machining milling Agricultural Machinery Spare Parts |

| Material : | Aluminum alloy 6061. 6063. 7075 .5082 and etc . steel alloy /stainless steel , titanium , brass/ copper , plastics and so on |

| Surface treatment : | painting , coating , oxide , anodized , powder coating , or according customer require |

| MOQ : | 10pcs |

| samples : | first will do samples send to customer test , after confirmed quality is ok , then do production |

| Package : | each parts will use foam pack , outer is wood box or pallet , strong package guarantee products no any damage ,injured during transportaion way. |

| Services : | customized , OEM/ODM service . machining service |

| Application : | automotive spare parts , motorcycle parts , machine , electronic spare parts etc |

| Market : | North American , european, middle east, african , Canada, Englad and so on |

Types of Ball Bearings

There are several types of ball bearings: Double-row angular contact, Four-point contact, Self-aligning, and Ceramic hybrid. Here’s a brief description of each. For more information, read our article about Double-row angular contact ball bearings. You’ll be better informed about how they’re made. Also, learn about how the cages that hold the balls in place are secured with rivets.

Double-row, angular-contact bearing

Double-row, angular-contact ball bearings are similar in their contact surfaces in one direction, and the two pairs of bearings are installed axially opposite to one another. This design allows them to support combined loads in axial and radial directions. These types of bearings are used for high-precision, high-speed applications. They can be used in everything from turbines to dentistry equipment. Double-row, angular-contact bearings are available at Grainger, as are single-row versions.

Double-row, angular-contact ball bearings are a popular option for applications where high precision and high speed are required. The design features of these bearings are ideal for applications with axial space restrictions. In contrast, they are smaller than two single-row angular-contact bearings and are available in steel, polyamide, or brass cages. Whether you need a cage for high speed or hard operating conditions is up to you. If you are unsure about the right cage for your application, contact Schaeffler.

Single-row angular-contact ball bearings are the most common type of bearings. Double-row bearings are also available with a shielded outer ring, which protects the balls inside the bearing from external contaminants. Because these double-row bearings are a good choice for applications requiring high performance, they are often the most affordable option. They offer similar performance as single-row bearings but are much more rigid.

Preloading is a key performance characteristic for double-row angular-contact ball bearings. Preloading can decrease the service life of double-row angular-contact ball bearings by up to 380 percent. Alternatively, you can preload double-row angular-contact ball bearings by placing spacers between their outer rings. Good double-row angular-contact bearing installation will increase working accuracy and bearing life.

Four-point contact ball bearing

The Four Point Contact Ball Bearing Market can be segmented into three types: 35 Degree, 45 Degree, and Other. The 35 Degree segment is expected to witness the fastest growth over the next few years, owing to its increased operational speed and competence in axial and radial axis load handling. Other types of four-point contact ball bearings include the Miniature and Deep Groove varieties. These are widely used in automobiles, aerospace, and other industries.

These bearings are designed for oil-free screw compressors, and they feature an outer-ring guided brass cage to reduce friction and increase running accuracy. In addition, they have lower maintenance costs compared to conventional bearings. However, they have a higher mean roughness value than their counterparts. High-speed operations require high-speed bearings that can withstand fast speed changes. This is because of the higher friction rate, which results from four-point contact.

The Four-Point Contact Ball Bearing is a highly versatile product, as it can handle radial, thrust, and moment loads. Because of this, it is often the first choice for slow to moderate-speed applications. This design also has a simplified assembly process, requiring only a single double-half-turn to install. It is the first choice of many automotive OEMs because it is extremely efficient. If you want a ball bearing with these benefits, you should contact a local bearing company.

The Four-Point Contact Ball Bearing Market will continue to grow despite a tough economy and volatile trade conditions. Demand for automotive and aerospace components is expected to grow alongside a variety of technological advancements. Meanwhile, demand for energy-efficient products will continue to increase with changes in trade policy, an imbalance in the supply-side ecosystem, and geopolitical risk. And while all these factors will continue to drive the market growth, a few challenges are worth considering.

The Four-Point Contact Bearing is designed with the same basic structure as its two-point counterpart. In a four-point contact ball bearing, one ball can have four distinct points of contact with two rings. Two of these contact points may be in diagonal position. The two remaining contact points change position and accommodate radial loads. Consequently, the Four-Point Contact Bearing is more flexible and robust than its two-point counterparts.

Self-aligning ball bearing

The self-aligning ball bearing is an incredibly useful tool in many industries. This type of bearing has a sealing lip that makes contact with a smooth chamfer on the inner ring. Because of the self-aligning nature of these bearings, they are not prone to misalignment. They can withstand temperatures ranging from -30°C to 120°C and should not be heated prior to installation.

A self-aligning ball bearing is an elastomer-based spherical-shaped bearing with two rows of rolling elements. These bearings can accommodate large radial loads, and their outer ring raceway is curved to provide a spherical effect. The inner ring, or cage, can be either cylindrical or conical. The inner diameter of a self-aligning ball bearing is normally cylindrical, but some are conical. They typically have three oil holes.

When choosing a self-aligning ball bearing, look for a model with a large enough bearing diameter to accommodate the shaft’s bending. Self-aligning bearings may also be interchangeable with standard ball bearing assemblies. You can find individual values in manufacturer catalogues. These bearings are useful in limited applications, although they are not necessarily ideal for everything. For example, in applications where combined loads are the main concern, self-aligning ball bearings should only be used if the application requires minimal misalignment.

A self-aligning ball bearing is a highly-efficient, energy-efficient solution for a variety of applications. It is a simple, low-maintenance solution that makes your life easier. Its unique outer raceway allows restraining springs to absorb the deflection that is common in other bearings. The result is a cooler, smoother running vehicle. It also helps prevent misalignment, which makes it ideal for use in many applications.

The SKF self-aligning ball bearing is an excellent choice for applications involving heavy deflection of the shaft. They are the lowest-friction bearing available. Their steel plate reinforced seals prevent them from separating from the shaft during operation. They are also resistant to oil, making them the perfect solution for high-speed applications. In addition to this, they are designed to work in a wide range of temperatures.

Ceramic hybrid ball bearing

A hybrid ball bearing made from a combination of steel and ceramics is a good option for high-speed applications requiring electrical isolation. This combination offers an extended lifespan and minimal electrical corrosion or seizure risk. In addition, the hybrid ball bearings have less friction than steel bearings and can operate at low speeds. To learn more about this hybrid type of bearing, continue reading. We’ll also discuss how it can help your application.

Full ceramic balls are generally harder than steel, but they do have lower density, meaning they’re not subject to the same high centrifugal forces as steel balls. These benefits make ceramic ball bearings much more durable, with long lifespans. Both full and hybrid ceramic ball bearings are available from CZPT. Read on to learn more about each type. Here’s a look at some of the benefits of each. You’ll be pleasantly surprised.

A hybrid ball bearing consists of steel inner and outer rings and a ceramic ball. It can withstand high speeds and loads, but it’s also designed to operate in extreme temperatures. This hybrid ball bearing also requires minimal lubrication and is suitable for a variety of applications. Because of its unique characteristics, hybrid bearings are lightweight and hard, and they spin faster than steel balls. But how do you choose the right one for your application?

A ceramic ball bearing is better than a steel one for many applications. Its greater speed capability and lower friction allow it to operate at higher speeds than steel balls. It is also less sensitive to fluctuations in lubrication conditions than steel balls. They also tend to be cheaper, so it makes sense to invest in one. It’s worth your while. They last longer, and they don’t require a run-in period.

A hybrid ball bearing is the best choice for electric spindles with high speed and heavy loads. A hybrid ceramic ball bearing has the advantage of low heat and high stiffness, and can operate at high speeds and loads. This thesis explores the dynamic characteristics of a hybrid ceramic ball bearing, including analysis calculations and experiment verification. The results provide reliable data and lay the foundation for professional spindle optimum design tests. It is a worthy addition to any machine shop.

China best CNC Machining A356 Aluminum Die Casting Parts for Agricultural Parts with Best Sales

Solution Description

Specialist OEM, ODM manufacturing facility

Die casting class: precision vehicle parts production

Die-forged aluminum alloy: ADC12, A360, A380, AlSi12(Cu), AlSi9Cu3(Fe), AlSi10Mg, and many others.

Die-casting equipment tonnage: 800T-2000T, 8 automatic die-casting generation traces

Aluminum die-casting mold: die-casting mildew design, stamping mold style and machining fixture layout

Surface therapy of aluminum areas: shot blasting, vibration sharpening, warmth treatment, impregnation, sprucing, portray, anodic oxidation, electrophoresis, electroplating, powder spraying

CNC precision machining: Mazak, Hyundai, Haas vertical and horizontal machining centers, CNC lathes, etc.

1. Solution materials: aluminum alloy, zinc alloy

two. Area treatment method: chrome plating, sandblasting, spraying, anodizing, powder spraying, electrophoresis

3. Delivery time: 8~twelve times

4. Relevant to various industries: automobiles, equipment, valves, pneumatics, and so forth.

5. The whole process contains: molds, die-casting molds, CNC machining, CNC milling equipment, stamping, injection molding, painting and powder coating, custom made assembly of cubs. Based on large-quality goods, superb services, sensible costs, and well timed shipping and delivery, we welcome consumers, business associations and buddies from all more than the planet to get in touch with us to seek out cooperation and obtain mutual benefit and CZPT outcomes.

workshop

Solid aluminum warmth dissipation chassis shell

Certification

HangZhou Century CZPT Machinery Co., Ltd.

How to find quality agricultural accessories

Agricultural accessories are very important in tractors, harvesters and more. If you’re in the market for new agricultural parts, you may want to choose steel. Steel is the best choice for agricultural equipment because it is corrosion-resistant, durable and cost-effective. However, you also need to consider other materials such as aluminum and plastic. Here are some tips for finding quality agricultural parts. Hope this information is helpful to you.

Steel is the best metal for farm equipment

Steel has many benefits, but why is it the best metal for farm equipment? Steel is lightweight and corrosion-resistant, making it ideal for agricultural applications. It has many other benefits, including resistance to chemical pesticides. Stainless steel is highly recyclable and has antimicrobial properties. It retains its integrity even when exposed to outdoor temperatures. It also has the added advantage of being able to withstand the rigors of agricultural life.

Agricultural machinery made of steel is also known for its durability. Agricultural equipment made of steel is known for its durability and ease of maintenance. Steel has a smooth surface that is easy to clean, which is especially important in dairy farming, where smooth surfaces are critical to maintaining the quality of raw milk. For those who need metal parts for agricultural equipment, Guocai is the best source. Their team of experts can help you find the right metal for your agricultural equipment and provide you with a complete metal fabrication service.

Agricultural equipment made of steel is often heavy, so finding ways to reduce weight is important. Aluminum alloys are a good choice because they are lighter than steel and suitable for dusty environments. Also, since they are more durable than steel, aluminum alloys are ideal for moving parts of agricultural machinery. Aluminum also has high tensile strength, making it ideal for dusty environments.

In addition to being sturdy and durable, the steel structure is low maintenance and ideal for storing agricultural equipment. They can hold multiple pieces of equipment and have an open interior, which means you can easily store other equipment inside. Due to the high technical content of farming, you may need to invest in a flexible steel building. To help you achieve these goals, CZPT offers agricultural buildings that are ideal for storing a variety of items.

Corrosion Resistance

Stainless steel is recommended for use in corrosive environments. Stainless steel is an alloy of iron, chromium, silicon and carbon. It also contains significant amounts of nickel and molybdenum. All stainless steels contain at least ten percent chromium. This alloy has excellent corrosion resistance and strength. There are certain applications where stainless steel is more suitable than traditional steel:

Agricultural components are often corroded due to their high carbon content. Depending on the metal and the environment, the resulting corrosion products may have different properties. The initial step of etching may result in the formation of ions. This ion then oxidizes further and forms oxides or other mixed valence compounds. The presence of dense oxide layers prevents further corrosion, but these layers are also porous. Therefore, the corrosion process can continue.

When selecting biomedical materials, researchers should test the corrosion resistance of materials. Normally, the pH of fluids in the human body is 7.4. However, during surgery, the pH of fluids in the body may change to a range of 5.5 to 7.8. After a few days, this pH will return to normal. Titanium and 316L stainless steel have better corrosion resistance than cobalt-based alloys.

Durable

Steel was first used in farm implements by John Deere, who introduced the steel plow in 1837. Steel makes plows more efficient and faster. Today, steel remains the most durable material used for farm implements, depending on the application. For example, heavy equipment is mainly made of steel. The tractor has a structural steel housing and a strong steel frame for corrosion resistance in agricultural environments. This is an advantage for farmers and agronomists.

Cost-effective

Farmers often purchase farm machinery directly, rather than renting or leasing accessories. This gives them ownership of the machine and is often more cost-effective in the long run. Also, buying equipment outright helps them establish equity. Farm machinery is expensive, so farmers are usually more willing to buy them. But leasing or renting parts is also a cost-effective option. Read on to learn more. What are the benefits of renting agricultural parts?

Agricultural equipment is made from many different materials and is often manufactured using an open or closed mold process. The use of thermoset composites is not uncommon, although reinforced thermoplastics are starting to gain traction in specific applications. For example, aerospace-grade prepregs are commonly used for cantilevers on sprayers. Alternatively, steel and aluminum arms are used for agricultural equipment, but require support structures to provide the required stability.

Easy to maintain

Many modern agricultural machines contain computer systems, sensors and other technologies that make them difficult to maintain without the help of experts. While not an impossible task, it does require specific diagnostic software and tools that most manufacturers don’t offer to the public. As a result, many farmers do not have access to the tools and diagnostic software needed to repair equipment and must take it to a licensed dealer for repairs.

Fortunately, there are some solutions to this problem. A recent executive order from President Biden, who oversees the federal government, calls for more competition in the economy. His executive order calls on the FTC to limit unfair trade practices and promote U.S. economic growth. One of the recommendations is that consumers have the right to repair farm equipment. Many agricultural products are affected by the new laws as they become more integrated and less competitive, meaning farmers and ranchers are forced to pay more for their produce.

in Saratov Russian Federation sales price shop near me near me shop factory supplier China Economic Floor Type CNC Lathe for Machining Flange manufacturer best Cost Custom Cheap wholesaler

EPG is a expert producer and exporter that is worried with the style, advancement and generation. The team is focused on making all selection of common roller chains and sprockets, gears & gearboxes, such as conveyor chain & sprockets , stainless steel chain, agricultural chain and has not just marketed its merchandise all over china, but also sold a lot more than 65% goods to oversees, such as Europe, America, South-east Asia, and it also has established up storage logistics in areas like Europe. In this way, our goods have continued to acquire market acceptance and consumers gratification in excess of the previous few a long time.

EPT EPTT EPTr Sort Lathe

For Turning Tyre Mildew,Grooves, Flange,EPTT,Wheel, Shaft,EPT Mould, Railway Components,Wheel Hub Turbine,and so on

one. OutstXiHu (West EPT) Dis.Hu (West EPT) Dis. Attributes:

All parts of EPTT are EPTTed foreign well-known brands, this kind of as FANUC or SIMENS EPTT Program/ SchneiEPTTEPT EPTT system, Japanese NSK EPTT, ABB EPT amp EPTT box/EPT box, and so forth. We can also configurate for each customer’s EPTT ask for and needs. Our Engineers can design distinct configurations according to distinct workpieces characteristics.

one.) This kind of lathe can be developed into CNC Milling Lathe which has functions of Milling and Turning, incXiHu (West EPT) Dis.Hu (West EPT) Dis. screw thread, conical surface area, curved floor, internal dull, etc.

2.) This lathe adopts frequency control system as its major EPT technique EPTn by frequency manage motor, the pace of primary-shaft realizes stepless pace regulating, as a result getting various speeds to fulfill rational reducing pace needs for the machining of distinct sort of operate-piece.

3.) This lathe is made up of lathe mattress, selective headstock, tailstock, blade adapter, electrical control program, lubrication program, and so on. Selective headstock and tailstock are set up at the left and rigEPTT aspect of lathe mattress respectively.

four.) The primary shaft can recognize stepless pace regulating in a selection of ten~300r/min and the main spindle entrance bearing adopts large-precision double row cylindrical roller bearings, obtaining large-degree of rigidity and rotary precision and effortless to adjust.

5.) EPT Rigidity, Stability and EPT Maintenance: All castings are created of substantial-toughness meehanite EPTT250. which is particularly ideal for large chopping. All massive castings stand the examination of annealing and vibration aging and inside stress is removed, so the all round precision is significantly improved and processed areas are identified with high geometric accuracy.

Our Theory : MaXiHu (West EPT) Dis.mize Customer’s Profitability unEPTTthe minimum spend EPT.

EPTT Lathe is Our EPT Qualities

Optional Choice:

one. EPTT, EPT Box,CNC EPTT System can be specified by customer

2. EPT Shield/Flash XiHu (West EPT) Dis.hu (West EPT) Dis. for EPTT can be optional

Application: This is a CNC horizontal roller lathe which is ideal for substantial-speed steel and carbide reducing tool to employ coarse and fantastic inventory getting rid of and slicing on the outer cylindrical surface of roller of different components it also can be utilized for rough and end machining of other shaft areas.

2. StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd EPTnical Parameters

| Name | CK61100 | CK61125 | CK61160 | CK61200 | CK61250 | |

| Description | Device | |||||

| Max. EPTg in excess of bed | mm | one thousand | 1250 | 1600 | 2000 | 2500 |

| Max. EPTg Above the skateboard | mm | 600 | 800 | 1200 | 1500 | 1800 |

| Max. WeigEPTT of Perform-piece | T | one | one | 2 | two | 3 |

| Max. Duration of Perform-piece | mm | seven hundred | seven-hundred | seven hundred | seven-hundred | 700 |

| EPTs of Spindle Pace | / | Infinitely Variable Speed/step-much less pace | ||||

| Assortment of Spindle Speed | r/Min | 10-300 | 10-two hundred | 10-160 | 10-one hundred sixty | four-80 |

| Chuck Diameter | mm | 800 | a thousand | 1250 | 1600 | 2000 |

| EPTT Diameter of Principal Entrance Shaft | mm | 190 | a hundred ninety | 220 | 220 | 300 |

| X,Z X,Z-AXiHu (West EPT) Dis.s Feed Assortment | mm/Min | -3000 | ||||

| Horizontal Stroke | mm | 500 | 650 | 800 | 1000 | 1250 |

| EPTTitudinal Stroke | mm | seven hundred | 700 | seven-hundred | 700 | seven hundred |

| Primary Driving EPT | Kw | Variable Frequency 11Kw-4 | Variable Frequency 15Kw-4 | Variable Frequency 22Kw-4 | Variable Frequency 30Kw-four | Variable Frequency 45Kw-4 |

Rermarks:

one. The above five designs of CNC Lathes are the stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd configurations, we can also layout and manufacture EPT lathe in accordance to the user’s workpiece attributes.

2. This series horizontal Lathe EPTTs have been exported to Norway, TEPTTd, Romania, Iran, Russia, Chile for machining railway components, car parts, mining and metallurgy, transport developing, wind EPTT and other EPTTry market.

EPT Customer’s Praise for our Solution and Administration

three. Soon after-sale Service and Upkeep

1. We supply expert technical education for users’ operators and upkeep employees to allow them to appropriately use and work the lathe and carry out regular routine maintenance.

2. Guarantee interval: 1 yr soon after acceptance of the lathe.

three. In situation of any high quality issue found during operation, the manufacturing unit will dispatch staff to the user’s place inside forty eight several hours (domestic consumers) amp inside of three daEPTT(EPT Client) and the complex staff will not likely leave before resolving the malfuntion.

4. The business will freely give different EPT and mechanical areas for the bought lathe well timed within warranty interval.

5. The firm will give lifetime assure for the consulting services in terms of application, routine maintenance, fix, renovation, and many others of equipments.

For a lot more particulars, you should truly feel free of charge to contact us. Many thanks!

in Udaipur India sales price shop near me near me shop factory supplier Precision CNC Machining Gear for Automobile manufacturer best Cost Custom Cheap wholesaler

EPG is a skilled maker and exporter that is worried with the design and style, growth and manufacturing. Our experts and engineers have 23 years of Encounter in the Bearing Business. A lot more importantly, we make special areas according to supplied drawings/samples and warmly welcome OEM inquiries.

EPT CNC Machining EPT for EPTT

one. Description

| No. | Merchandise | Description |

| one | Identify | EPT EPT |

| 2 | Size | EPT can be EPT. |

| 3 | Manufacture StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd | five-8 Grade ISO1328-1997. |

| four | EPT | 45#Steel,20CrMnTi,40Cr,20CrNiMo,20MnCr5,GCR15SiMn,42CrMo,2Cr13stainless steel,Nylon,Bakelite,Copper,Aluminium.and many others |

| five | Production Process | The principal procedure is EPT Hobbing, EPT Shaping and EPT EPT, Choosing production approach in accordance to the distinct goods. |

| 6 | Heat Remedy | Carburizing and quenching ,EPT-frequency quenching,Nitriding, Hardening and tempering, Selecting heat therapy according to the various materials. |

| seven | Screening EPT | Rockwell hardness tester 500RA, EPTT mesh instrument EPTT-200B amp 3102,EPT measurement cEPTTr instrument CNC3906T and other EPT precision detection equipments |

| 8 | Certification | GB/T19001-2016/ISO9001:2015 |

| 9 | Use | Used in printing EPTT, cleaning EPTT, healthcare equipment, XiHu (West EPT) Dis.Hu (West EPT) Dis.den EPTT, development EPTT, electric powered auto, valve, forklift, transportation tools and numerous EPT EPTTs.etc |

| ten | Package deal | According to customer’s request |

2. Images

three. OrEPTTprocess

a. Consumer sends us the drawing or sample, If only sample, our company offer the CAD drawing.

b. Our firm provides the processing strategy and quotation.

c. Our company supplies the sample soon after client confirmed processing method and quotation.

d. Client areas the orEPTTafter validate the sample.

e. Customer shell out 50% deposit

f. EPTtity manufacturing.

g. Shell out the balance soon after the acceptance and confirmation.

h. Supply.

in Guatemala City Guatemala sales price shop near me near me shop factory supplier Customized Bevel Gear Spur Gear with CNC Machining manufacturer best Cost Custom Cheap wholesaler

A lot more importantly, we make particular areas according to provided drawings/samples and warmly welcome OEM inquiries. Because of to our sincerity in giving best services to our consumers, comprehending of your needs and overriding feeling of obligation towards filling buying needs, Getting gathered cherished experience in cooperating with international buyers,

EPTT EPTTl EPT spur EPT with cnc machining

one. Item Information:

EPT: metal, stainless steel, carbon steel,

EPTT: precision casting

Surface area treatment: sand blast, poEPTTng, painting, powEPTTcoating

Machining: grinding, tapping, drilling, cnc

Application: engineering EPTTry components, agricultural casting, building equipment

two. Solution Images:

| Processing | CNC Machining, Turning, Milling, Stamping, Die EPTT, EPT mould,4 amp5 aXiHu (West EPT) Dis.s machining |

| Relevant EPT | EPTT/zinc alloy, iron, metal alloy, plastic, brass, steel, and stainless metal |

| Surface therapy | poEPTTng,zinc plating,nickel plating,chrome plating,anodizing. |

| Drawing format | IGS,SLD 2012,X_T,STEPT,CAD 2012 and PDF |

| Annual Capability: | 200,000pcs |

| EPTT EPTT | ISO 9001, TS 16949, AS 9100C |

| Tolerance: | /-.005mm |

| EPT Time: | 7-fifteen times |

| QC Method: | Pick or 100% inspection just before shipment. |

| Cargo Terms: | express ampair freigEPTT precedence/sea freight/ As for every EPT technical specs |

EPTTngdao XiHu (West EPT) Dis.hu (West EPT) Dis. EPTTry EPTT,Ltd.

CNC machining:

Inspection method:

In orEPTTto make certain the good quality of the orders, our impartial QC users to have out strict inspection at each and every phase:

Package:

1.) wooden, carton

2.) pallet

three.) as customers’ requirement.

Our Solutions

1) Encounter in casting for numerous years and served buyers all about the globe.

2) Worldwide EPTd-stage gear this kind of as CNC, numerical lathes, CMM.

three) OEM service, you demand from customers is our pursued.

4) ISO top quality handle

FAQ

- 1. How can I get thequotation?

Please ship us data for estimate: drawing, materials, excess weight, quantity and request.

- 2. If we don’t have drawing, can you make drawing for me?

Yes, we make the drawing of your sample and copy the sample.

- three. When can I get thesample?

Sample: twenty five-thirty days right after you begin to make mold. The precise time relies upon on your merchandise.

- four. What is your principal orEPTTtime?

OrEPTTtime: 35-40 days soon after the payment. The correct time is dependent on your merchandise.

- five. What is yourpayment method?

EPT: 100% TT EPTd.

Primary purchase: 50% deposit, stability fifty% to be compensated just before cargo.

- six. Which sort of file format you can study?

PDF, ISGS, DWG, STEPT, MAX..

- seven. If you export to our nation just before, can I get the data of your EPTT buyer in our place?

We can’t offer you you all the data of our client simply because we have responsibility to safeguard our customers’ privateness. But we can offer you some component of B/L.

in Puerto Vallarta Mexico sales price shop near me near me shop factory supplier High Precision C45 Steel CNC Machining Gear Rack manufacturer best Cost Custom Cheap wholesaler

We can source a total-selection of electricity transmission merchandise like chains, sprockets and plate wheels, pulleys, gearboxes, motors, couplings, gears and racks. We are aiming to meet the calls for of the clientele around the globe.. The higher specific CNC gear, this sort of as Gradual-feeding wire-lower device, jig grinding device and electrical discharge device, makes certain the leading high quality precision of mould processing, with the large efficient and environmental security acid rolling line being the greatest raw content changing tools in the subject in china The wildly use of computerized milling machine, higher-pace automatic feeding punch, substantial speed automatic rolling and assembling machine assures the substantial quality and effectiveness of components and chain making. CNC rack and pinion EPTs higher quality low cost custom measurement

| Product quantity | M1-M12 |

| EPT | Brass, C45 metal,Stainless steel,Copper,POM,EPTT,Alloy and so on |

| Surface treatment | Zinc plated, Nickel plated, Passivation, OXiHu (West EPT) Dis.dation, Anodization, Geomet, Dacromet, Black OXiHu (West EPT) Dis.de, Phosphatizing, PowEPTTCoating and Electrophoresis, and so on |

| StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd | ISO, DIN, EPTT, JIS, BS and Non-stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd. |

| EPT | DIN6,DIN7,DIN8,DIN9. |

| Teeth therapy | Hardened,Milled or Ground |

| Tolerance | .001mm-.01mm-.1mm |

| Finish | shot/sand blast, warmth therapy, annealing, tempering, poEPTTng, anodizing, zinc-plated |

EPT demonstrate

Workshop

Machining gear

Measurement for tooth

EPTT display

FAQ

Q1. What is your conditions of EPTT?

A: EPTTly, we pack our products in solitary colour box. If you have EPTT request about EPTT, pls negotiate with us in EPT, we can pack the goods as your request.

Q2. What is your phrases of payment?

A: T/T thirty% as deposit, and 70% before shipping and delivery. We will show you the images of the goods and deals

before you shell out the equilibrium. Other payments phrases, pls negotiate with us in EPT, we can talk about.

Q3. What is your phrases of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your supply time?

A: EPTTly, it will consider twenty five to thirty daEPTTafter acquiring your EPT payment. The distinct supply time depends

on the objects and the amount of your get.

Q5. Can you produce in accordance to the samples?

A: Sure, we can generate by your samples or complex drawings. We can develop the molds and fixtures.

Q6. What is your sample coverage?

A: We can provide the sample if we have prepared parts in inventory, but the customers have to spend the sample EPT and

the courier EPT.We welcome sample purchase.

Q7. Do you examination all your merchandise prior to supply?

A: Yes, we have a hundred% test before shipping

Q8: How do you make our business EPTT-expression and good partnership?

1. We hold good quality and aggressive cost to ensure our consumers reward

two. We regard every single buyer as our friend and we sincerely do organization and make close friends with them,

Best China manufacturer & factory high in Faisalabad Pakistan demand industrial precision aluminum cnc machining parts Motorcycle wheel With high quality best price

Our goods are applied in numerous fields.

Overview

Quick Details

-

The star tube is ideal for programs with higher torque peaks that could be dangerous to the other tube shapes. The star tube with 6 speak to factors is also the chosen decision when transmissions exceed 1600mm in duration and when the speed is a thousand rpm. AG sequence with splined tube The splined tube is advised for very limited PTO shafts. The splined telescopic shaft permits bushing and splined couplings of only one hundred-120mm. The dimensions of the cross joints differ from 22mm diameter up to 48mm diameter and let power transmission of up to 250HP.

- Relevant Industries:

-

Producing Plant

- Model Title:

-

OEM

- OEM Service:

-

Assistance

- Tolerance:

-

.01-.05mm or Custom-made

Accudrive Servo Gearheads Servo drives from EPG Push benefit from the expertise and innovation of our much more standard manufacturers. Offered in both appropriate angle and inline configurations, coupled with the availability of several precision amounts, you are certain to find the proper product for your application.EPG Travel Accudrive Servo Gearhead

- Certification:

-

ISO9001, SGS

- Floor Remedy:

-

Sandblasting,Sprucing,Anodize, Zinc,Nickel,Chrome,Plating, and so on.

- Application:

-

Automobile,Health care Equipments,Electric Equipment,Components,and so on.

- Dimension:

-

As Customers’ Ask for

- Gear:

-

Milling/Lathe/Drilling/4/Three Axis CNC Machining Heart

- Drawing Format:

-

Professional/E, Auto CAD, Strong Functions,IGS,UG, CAD/CAM/CAE

Supply Capacity

- Offer Ability:

- ten thousand Piece/Parts for every Month

Packaging & Delivery

- Port

- nb

-

Lead Time

: -

Amount(Parts) 1 – 500 >500 Est. Time(times) thirty To be negotiated

Online Customization

|

Item Name |

higher demand industrial precision aluminum cnc machining parts Bike wheel |

|

Product Type |

CNC turning, milling, drilling, grinding, wire EDM chopping and so on. |

|

Our Solutions |

CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Creating,and many others |

|

Material |

Aluminum,Brass,Stainless Steel,Copper,Plastic,Wooden,Silicone,Rubber,Or as for each the customers’ demands |

|

Surface area Remedy |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Sharpening,Laser Engraving |

|

Dimension |

As customers’ request |

|

Support Venture |

To supply creation style, generation and technological provider, mould development and processing, and so on |

|

Drawing Structure |

Professional/E, Auto CAD, Solid Functions,IGS,UG, CAD/CAM/CAE |

|

Screening Machine |

Digital Top Gauge, caliper, Coordinate measuring device, projection device, roughness tester, hardness tester and so on |

|

Business employed |

Equipment hefty obligation products digital unit Auto spare components optical telecommunication |

|

Packing |

Eco-friendly pp bag / EPE Foam /Carton bins or wood boxes |

|

Trial sample time |

seven-10 times right after confirmation |

|

Delivery time |

seven-30 days right after get the pre-payments |

|

Payment Phrases |

T/T,Western Union,Paypal |

Best China manufacturer & factory Custom in Detroit United States Fabrication Services cnc machining turning aluminum part cnc machining auto parts With high quality best price

We also can design and make non-standard products to meet customers’ special requirements.

Overview

Quick Details

The company covering 88,000 square meters, has advanced equipment and strong technical strength, such as the numerical control machine tools and machining centers, CAD/CAM system, industrial robot etc.

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- OEM Service:

-

Support

- Tolerance:

-

0.01-0.05mm or Customized

- Certification:

-

ISO9001, SGS

- Surface Treatment:

-

Sandblasting,Polishing,Anodize, Zinc,Nickel,Chrome,Plating, etc.

- Application:

-

Automobile,Medical Equipments,Electric Appliance,Hardware,etc.

- Dimension:

-

As Customers’ Request

- Equipment:

-

Milling/Lathe/Drilling/Four/Three Axis CNC Machining Center

- Drawing Format:

-

PRO/E, Auto CAD, Solid WorksIn close consultation with the customer, the design of special gearboxes and high-precision gearing components are individually customized to the technical and operational requirements. For special requirements such as HIGH SPEED, low noise or HIGH TORQUE, we develop optimal customer solutions thanks to our many years of experience and expertise. Furthermore, we provide support in the assessment of load tests and product engineering optimization. Owing to our steadily developing expertise, this results in tailor made high-end solutions, which we produce in-house.,IGS,UG, CAD/CAM/CAE

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

PTO Adapters To avoid potential connectivity issues, you may want to consider a PTO Adapter for your tractor. The PTO adapter extends the connection to the implement, providing additional space for the PTO shaft to turn without touching the Arm Weldment or other parts of your tractor or the implement.

- Port

- nb

-

Lead Time

: -

Quantity(Pieces) 1 – 500 >500 Est. Time(days) 30 To be negotiated

Online Customization

Custom Fabrication Services cnc machining turning aluminum part cnc machining auto parts

Product Description

| Product Type | CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

| Our Services | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

| Material | Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,Or as per the customers’ requirements |

| Surface Treatment |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

| Dimension | As customers’ request |

| Service Project | To provide production design, production and technical service, mould development and processing, etc |

| Drawing Format: | PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

| Testing Machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

| Industry used | Machinery; heavy duty equipment; electronic device; Auto spare parts; optical telecommunication |

| Packing | Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes As customer’s specific requirements |

| Trial sample time | 7-10 days after confirmation |

| Delivery time | 7-30 days after receive the pre-payments |

| Payment Terms | T/T,Western Union,Paypal |

OEM Service

OEM Parts

Surface Treatment

Production Process

Why Us