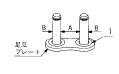

Connecting Hyperlink – Press Fit (BS/DIN/ANSI)

The common connecting website link for ANSI series detachable chains, also applied on riveted chains where substantial speeds or arduous situations are encountered. Provided with two connecting pins riveted into the outer plate, the other outer plate being a press fit onto the pins and secured by split pins soon after assembly. Press match connecting hyperlinks can only be used as soon as; new backlinks have to usually be utilized to exchange dismantled links.

Cranked hyperlinks

Aside from the specialized chains exactly where the cranked website link is an essential design feature, cranked backlinks are applied only wherever the chain length has to be an odd variety of pitches. This practice will not be proposed; all drives should, wherever possible, be built with adequate all round adjustment to make certain the use of an even amount of pitches during the chain. Usually do not USE CRANKED Back links ON IMPULSIVE, Highly LOADED OR Higher Speed DRIVES.

Cranked Website link – Slip Fit (BS/DIN) Offset Hyperlink – Slip Match (ANSI)

A single link with cranked plates pressed onto a bush and roller  assemble on the narrow end. A clearance fit connecting pin (No. 128) is fitted at the broad finish and is secured by a split pin.

assemble on the narrow end. A clearance fit connecting pin (No. 128) is fitted at the broad finish and is secured by a split pin.

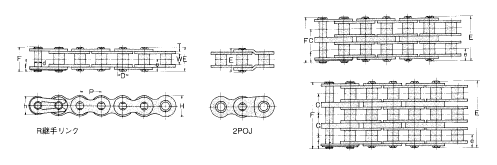

Cranked Website link Double (BS/DIN) Two Pitch Offset Link (ANSI)

Double cranked back links are available for most sizes and varieties of chain. The unit consists of an inner hyperlink (No. 4), with cranked hyperlinks retained completely in place by a riveted bearing pin. Screw operated extractors break chain by forcing the end softened bearing pins out of the outer hyperlink plates. For other brand names of chain, the rivet swell must to start with be ground away.

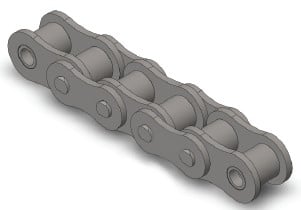

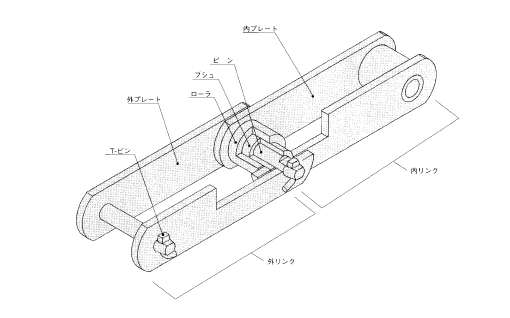

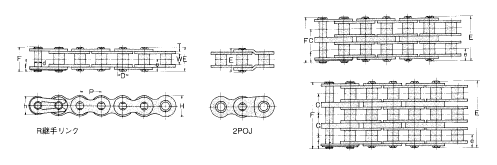

Precision Roller Chain, Components and Connecting Hyperlinks

The precision steel roller chain is usually a remarkably productive and versatile suggests of transmitting mechanical electrical power, which, while in the area of industrial applications, has practically totally superseded all other forms of chain previously employed.

Outer Website link – Press Match (BS/DIN) Riveting Pin Website link – Press Match (ANSI)

For use with all sizes and types of chain the place optimum security is desired. The website link is provided with bearing pins riveted into one outer plate. Another outer plate is surely an interference match around the bearing pins, the ends of which need to be riveted in excess of soon after the plate is fitted. Press fit connecting back links ought to only be utilised the moment; new hyperlinks need to be utilised to exchange dismantled links. (See ‘Riveting Chain Endless’ for total guidelines).

Connecting Website link – Slip Fit (BS/DIN/ANSI)

A connecting link supplied with two connecting pins riveted to the outer plate. The outer plate is actually a clearance fit within the connecting pins and it is secured in place by a split pin with the projecting end of each connecting pin.

Connecting Hyperlink – Slip Match  (BS/DIN/ANSI)

(BS/DIN/ANSI)

Utilised on short pitch chains only. Provided with two connecting pins riveted to the outer plate, the clearance fit connecting plate currently being secured by way of a spring clip, No. 27, which snaps into the grooves during the pins.

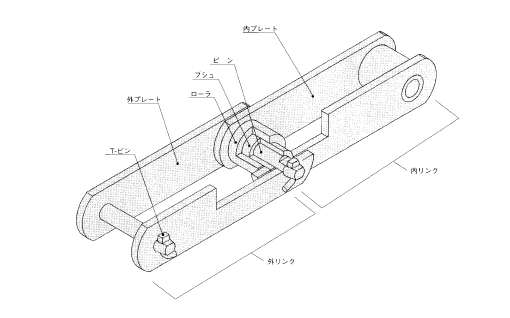

Precision Roller Chain, Components and Connecting Links

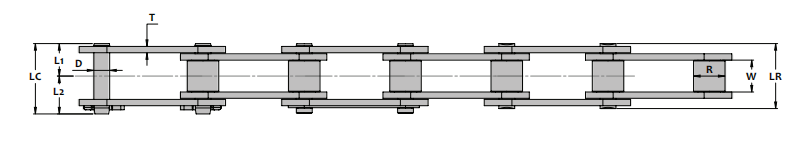

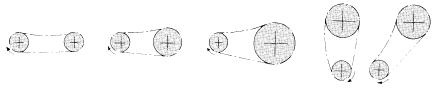

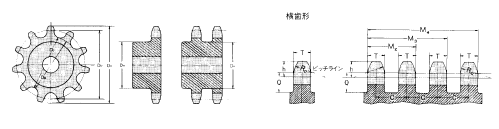

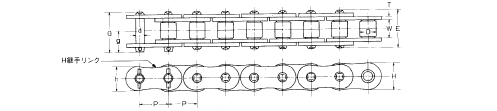

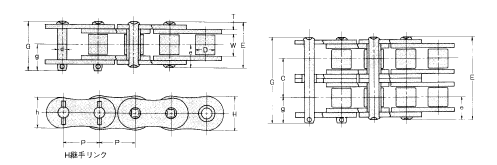

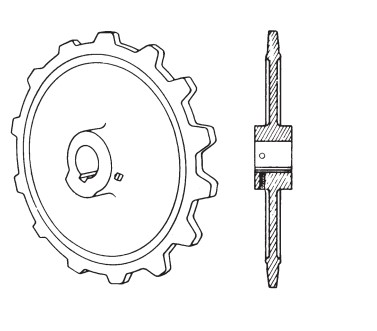

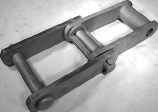

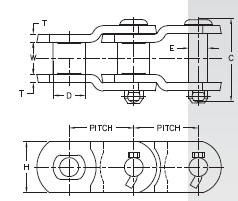

The precision steel roller chain is actually a highly effective and versatile implies of transmitting mechanical energy, which, while in the  discipline of industrial applications, has nearly entirely superseded all other varieties of chain previously utilised. The illustration below demonstrates element components of the outer link and on the inner website link of the easy roller chain. As illustrated, the precision steel roller chain consists of a series of journal bearings held in precise relationship to each other through the constraining link plates. Each bearing consists of a bearing pin and bush on which the chain roller revolves. The bearing pin and bush are case hardened to permit articulation below high pressures, and to contend with the load carrying pressures and gearing action imparted by way of the chain rollers. All chains are classified according to pitch (the distance amongst the centers of adjacent bearing pins), roller diameter and width amongst inner plates. Collectively, these dimensions are referred to as the gearing dimensions, as they decide the form and width of the sprocket teeth.

discipline of industrial applications, has nearly entirely superseded all other varieties of chain previously utilised. The illustration below demonstrates element components of the outer link and on the inner website link of the easy roller chain. As illustrated, the precision steel roller chain consists of a series of journal bearings held in precise relationship to each other through the constraining link plates. Each bearing consists of a bearing pin and bush on which the chain roller revolves. The bearing pin and bush are case hardened to permit articulation below high pressures, and to contend with the load carrying pressures and gearing action imparted by way of the chain rollers. All chains are classified according to pitch (the distance amongst the centers of adjacent bearing pins), roller diameter and width amongst inner plates. Collectively, these dimensions are referred to as the gearing dimensions, as they decide the form and width of the sprocket teeth.

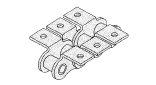

Regular backlinks

The chain parts and connecting links illustrated are only indicative of your styles obtainable. Please refer on the ideal solution webpage for your elements relevant to person chains.

These are complete assemblies for use with all sizes and types of chain. The unit consists of two inner plates pressed on towards the bushes which carry the rollers. (Inner back links for use with bush chains have no rollers).

STAINLESS STEEL CHAIN

The consolidation of Viking Chains Group into

Connexus Industries has allowed the continuation from the VC Brand of Steel Chains. The VC Brand says good quality manufacturing course of action, and lengthy services life. This successful brand involves the next:

WELDED STEEL CHAIN

? Full Press Match Rivets

? Parallel Sidebar Holes

? Substantial Good quality Material & Heat Treating

WELDED STEEL PLUS

? Welded flush on outside eliminates any

interference with sprockets

? Parallel holes for “True-Fit”

? Seamless Barrels eliminate

“Premature Stretch”

WELDED STEEL DRAG CHAIN

? Fully Heat Treated Barrels

? Complete Press Match Rivets

? Parallel Sidebar Holes

? Higher Top quality Material & Heat Treating

DOUBLE LENGTH INFEED CHAINS, SCANNING CHAINS, FLIGHTS, SPROCKETS AND BEDPLATES

? Specifically Constructed to withstand Large Speed, Impact applications

? Industry Leader for 25 plus years

? Custom Solutions

SUGAR MILL CHAINS

? Designed for Extended Support existence in Sugar  Mill applications

Mill applications

? Heat Treated Stainless Steel, Hard Chrome options available

? Standard and Custom attachments

SPECIALTY CHAINS FOR ALL MARKETS

Mill chain

I’Anco Cast alloy steel and Hadfield manganese steel mill chains are designed for the most severe support applications in wood processing facilities today. They are designed to handle extreme wear, substantial tensile loads and extreme impact. Our ability cast attachments integral to the link eliminates any chance of creating heat affected zones by welding; however, the materials are readily weldable allowing for quick turnaround times for custom attachments. All of our cast links have recessed head and rivet ends offering protection from side wear on the rivets. This also allows us to pour the links with heavier cross sections adding to the overall strength of your chains plus creating larger bearing surfaces to distribute the loads over a larger area reducing the wear on the side bars.

STAINLESS STEEL CHAIN

The consolidation of Viking Chains Group into

Connexus Industries has permitted the continuation with the VC Brand of Steel Chains. The VC Brand says excellent manufacturing system, and prolonged service existence. This prosperous brand incorporates the following:

WELDED STEEL CHAIN

? Total Press Match Rivets

? Parallel Sidebar Holes

? Substantial High quality Materials & Heat Treating

WELDED STEEL PLUS

? Welded flush on outside eliminates any

interference with sprockets

? Parallel holes for “True-Fit”

? Seamless Barrels eliminate

“Premature Stretch”

WELDED STEEL DRAG CHAIN

? Fully Heat Treated Barrels

? Total Press Match Rivets

? Parallel Sidebar Holes

? Large High quality Material & Heat Treating

DOUBLE LENGTH INFEED CHAINS, SCANNING CHAINS, FLIGHTS, SPROCKETS AND BEDPLATES

? Specifically Constructed to withstand Higher Speed, Impact applications

? Industry Leader for 25 plus years

? Custom Solutions

SUGAR MILL CHAINS

? Designed for Lengthy Services life in Sugar Mill applications

? Heat Treated Stainless Steel, Hard Chrome options available

? Standard and Custom attachments

SPECIALTY CHAINS FOR ALL MARKETS

Mill chain

I’Anco Cast alloy steel and Hadfield manganese steel mill chains are designed for the most severe service applications in wood processing facilities today. They are designed to handle extreme  wear, high tensile loads and extreme impact. Our ability cast attachments integral to the link eliminates any chance of creating heat affected zones by welding; however, the materials are readily weldable allowing for quick turnaround times for custom attachments. All of our cast links have recessed head and rivet ends offering protection from side wear on the rivets. This also allows us to pour the links with heavier cross sections adding to the overall strength with the chains plus creating larger bearing surfaces to distribute the loads over a larger area reducing the wear on the side bars.

wear, high tensile loads and extreme impact. Our ability cast attachments integral to the link eliminates any chance of creating heat affected zones by welding; however, the materials are readily weldable allowing for quick turnaround times for custom attachments. All of our cast links have recessed head and rivet ends offering protection from side wear on the rivets. This also allows us to pour the links with heavier cross sections adding to the overall strength with the chains plus creating larger bearing surfaces to distribute the loads over a larger area reducing the wear on the side bars.

Stainless-steel CHAIN

Intended for food stuff applications as well as in places the place wash-down, steam, and

chemical compounds are widespread.

DRAG CHAIN

Present efficient indicates to  convey.

convey.

sawdust, chips or bark dust. Long

run lifestyle in sluggish pace apps.

81X ENGINEERING Course CHAIN

Generally utilized for slow to average pace drives and conveyor apps.

Popular attachments contain bullnose UHMW, plastic caps, camelbacks,

trimmer lugs and pusher lugs.

AGRICULTURAL Course CHAIN

Built to face up to the cruel

natural environment from the agriculture

business. Long-lasting, with fewer

maintenance.

LEAF CHAIN

Leaf chain is employed for applications that call for strong versatile linkage for transmitting movement or raise.

Electric power TRANSMISSION CHAIN

Made to deliver a versatile means of electric power transmission. Out there in both offset and straight sidebar configuration.

DOUBLE FLEX CHAIN

Built for conveying applications the place bend radius is necessary for product move change of course.

SHARP Prime CHAIN?

Excellent solution to extend feed speeds. Out there in many tooth profile patterns. Number one alternative of initial devices suppliers.

WELDED Metal MILL CHAIN

Especially made to offer efficient signifies to express products in currently??¥s

most tricky content handling apps. Welded attachments are available in numerous kinds.

ROLLER CHAIN

Excellent for industrial and agriculture purposes. Plates and rollers are shot peened and pre-stretched at manufacturing unit for increased toughness and longer lifetime.

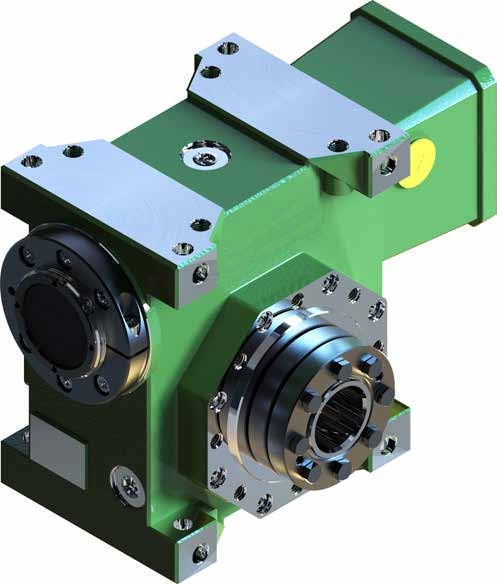

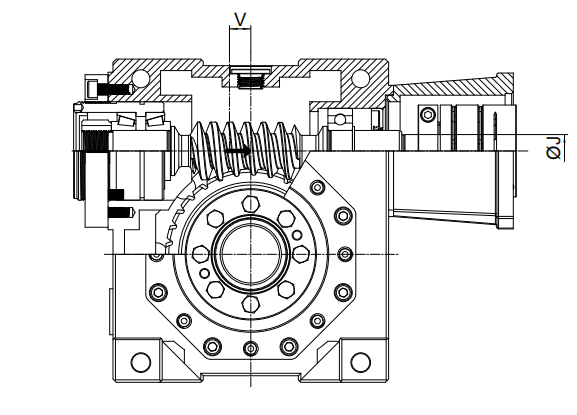

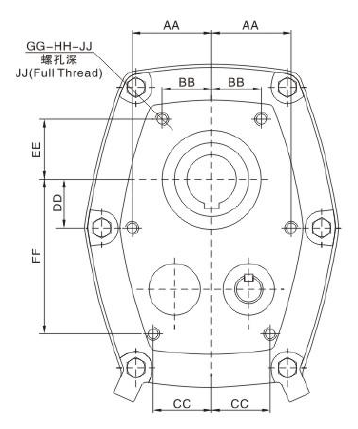

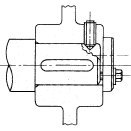

SMR Reducer Specification

one, Output Hubs

Typical or option hubs with metric bores can be found to suit global shaft diameters.

2, Precision Superior quality Gearing

Computer Built Helical Gear. Solid Alloy Components for High Load Capacity, Case Carburized for lengthy lifestyle, Ground Profile (some intermediate pinions are shaved), Crown tooth Profile, In Conformance with ISO 1328-1997, 98% Efficiency for per Stage, Smooth Quiet Operation with Teeth in  Mesh.

Mesh.

three, Maximum Capability Housing Style and design

Shut Grain Cast Iron Development, Excellent Vibration Dampening & shock Resistance features, Precision Bored and Dowelled to Ensure Accurate In-line Assembly.

4, Powerful Alloy Steel Shafts

Sturdy Alloy Steel, Hardened, Ground on journals, Gear Seatings and Extensions, for Highest Load and Greatest Torsional Loads, Generous Sizes Shaft Keys for Shock Loading and Conform to ISO Standards.

5, Additional Case Lugs (Except H and J Gear Case)

Eliminates the Need for Critical Tightening of Torque arm Bolts, Controls Position of Common Torque Arm Mounting within Recommended limits.

6, Backstops

Alternate Parts, Anti-run Back Device, Are available on all 13:one and 20:1 Ratio units and do not recommend for 5:one Units.

7, Bearing and Oil seals

Bearing are Adequately Proportioned and Conform to ISO dimension plan, Readily Readily available World-wide, Oil seals are Double.

Lipped Garter Spring Type, Ensuring Effective Oil Sealing.

8, Rubberised End Caps

Self sealing Intermediate Cover Plates, to Regular ISO Housing Dimensions.

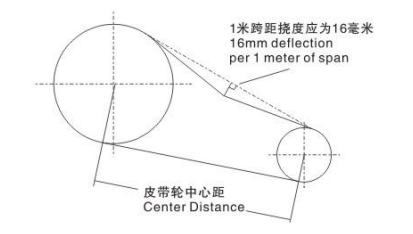

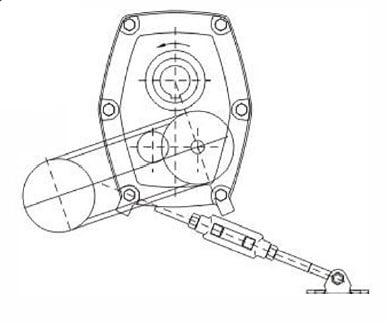

9, Torque Arm Assembly

For Easy Adjustment of the Belt.

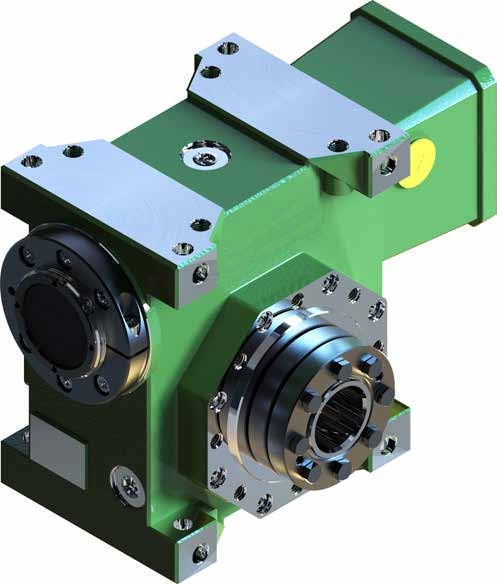

SMR Reducer Specification

one, Output Hubs

Conventional or option hubs with metric bores can be found to suit global shaft diameters.

two, Precision Superior quality Gearing

Laptop or computer Intended Helical Gear. Strong Alloy Elements for Higher Load Capacity, Situation Carburized for extended life, Ground Profile (some intermediate pinions are shaved), Crown tooth Profile, In Conformance with ISO 1328-1997, 98% Efficiency for per Stage, Smooth Quiet Operation with Teeth in Mesh.

three, Highest Capacity Housing Style

Shut Grain Cast Iron Development, Exceptional Vibration Dampening & shock Resistance features, Precision Bored and Dowelled to Ensure Accurate In-line Assembly.

4, Sturdy Alloy Steel Shafts

Strong Alloy Steel, Hardened, Ground on journals, Gear Seatings and Extensions, for Optimum Load and Highest Torsional Loads, Generous Sizes Shaft Keys for Shock Loading and Conform to ISO Standards.

5, Additional Case Lugs (Except H and J Gear Case)

Eliminates the Need for  Critical Tightening of Torque arm Bolts, Controls Position of Standard Torque Arm Mounting within Recommended limits.

Critical Tightening of Torque arm Bolts, Controls Position of Standard Torque Arm Mounting within Recommended limits.

6, Backstops

Different Parts, Anti-run Back Device, Can be found on all 13:1 and 20:one Ratio units and do not recommend for 5:one Units.

7, Bearing and Oil seals

Bearing are Adequately Proportioned and Conform to ISO dimension plan, Readily Readily available World-wide, Oil seals are Double.

Lipped Garter Spring Type, Ensuring Effective Oil Sealing.

8, Rubberised End Caps

Self sealing Intermediate Cover Plates, to Standard ISO Housing Dimensions.

9, Torque Arm Assembly

For Easy Adjustment of the Belt.

JDLB Features

Servo worm gear units have six styles :45 – 50 – 55 – 63 – 75 – 90, with dual lead worm drive. Left and right flank of worm shaft employing diverse lead angle creating tooth thickness gradual transform. To ensure that you are able to move worm shaft

and adjust backlash.

JDLB Applications

Precision rotary motion

— Lowering the noise and vibration that is caused through the load transform as well as the

modify of cutting force.

— cutting down the noise and influence that is definitely brought on through the corotation and reverse.

— By reducing worm abrasion.

— Escalating worm output response speed.

Precision Indexing device

— CNC machine, assembly line, cutting machine, transmission lines, etc.

— Indexing device, correct reading through mechanism need precise motion

events.

Velocity altering circumstances.

— Minimizing the noise plus the affect  that’s brought about by pace transform.

that’s brought about by pace transform.

— Lowering the worm abrasion that is certainly brought about by speed improvements.

JDLB Make selection

The following headings have details on crucial elements for

selection and correct utilization of gearbox.

For particular data around the gearbox variety, see the related chapters.

EFFICIENCY

Efficiency is really a parameter which includes a significant influence over the sizing of specified applications, and generally depends upon gear pair layout factors.

The mesh data table on web page 9 demonstrates dynamic efficiency (n1=1400)and static efficiency values.

Do not forget that these values are only accomplished following the unit has become run in and is with the working temperature.

JDLB series large precision worm gear is an great substitute for

precision planetary gearbox, the products manufacturer can

substantially decrease the price of applying precision planetary gearbox.

Hollow output with shrink disc, high precision, for easy integration.

Output with keyway, handy set up, effortless integration.

Solid shaft output (single, double), high stiffness, regular alternative.

The designer’s perfect remedy would be to rotate 90 degrees to put in the servo motor drive programs.

Worm shaft in series is often driven by one particular motor to accomplish synchronous output of a number of worm wheels. It’s been applied in

automatic polishing cell phone shell and also other equipments.

Optimized get hold of pattern

* Innovative processing technological innovation and precision assembly to be sure the correct meshing with the tooth and decrease get in touch with worry with the tooth surface.

* Special worm wheel bronze alloy can make the teeth have large power and great dress in resistance.

* Which has a massive ratio of tooth surface make contact with, worm wheel is not simple to put on, it can sustain the locked backlash.

Optimized adjustment structure

* Speedily setting backlash.

* Increased stiffness and precision.

* Patent structure.

Servicing absolutely free

* Large performance synthetic lubricant.

* Closed framework, no want to replace lubricant oil.

Rapidly install servo motor

* Higher stiffness and minimal inertia coupling for servo motor.

* Several different flanges is usually matched using the servo motor.

Set up two taper roller bearings with which have longer services lives.

* Eliminates worm shaft alignment problems.

* Bearing pre-tight set up, with higher assistance stiffness.

Worm shaft using Taper roller bearings.

* Installed two taper roller bearings with which have longer services lives.

* Eliminates worm shaft  alignment challenges.

alignment challenges.

* Bearing pre-tight set up, with higher support stiffness.

Output torsional backlash available in 2 ranges:

* Ultra precision: 1 arc minute for that most demanding applications.

* Precision: two to four arc minutes an excellent compromise rate and excellent.

Housing with gravity casting

* High strength Aluminum Alloy casting and heat treatment.

* Superior rigidity and very low excess weight.

* Beautiful form and Great weather resisting residence.

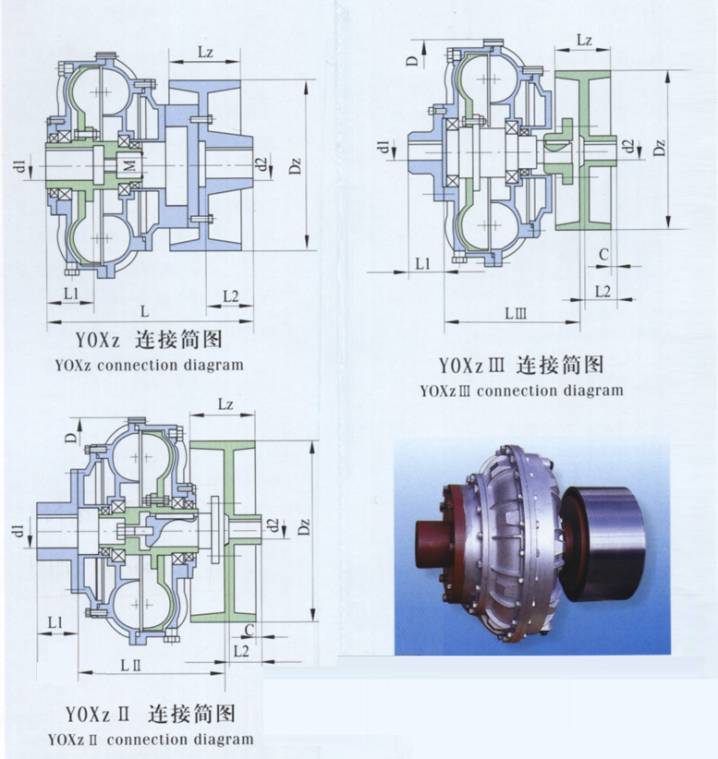

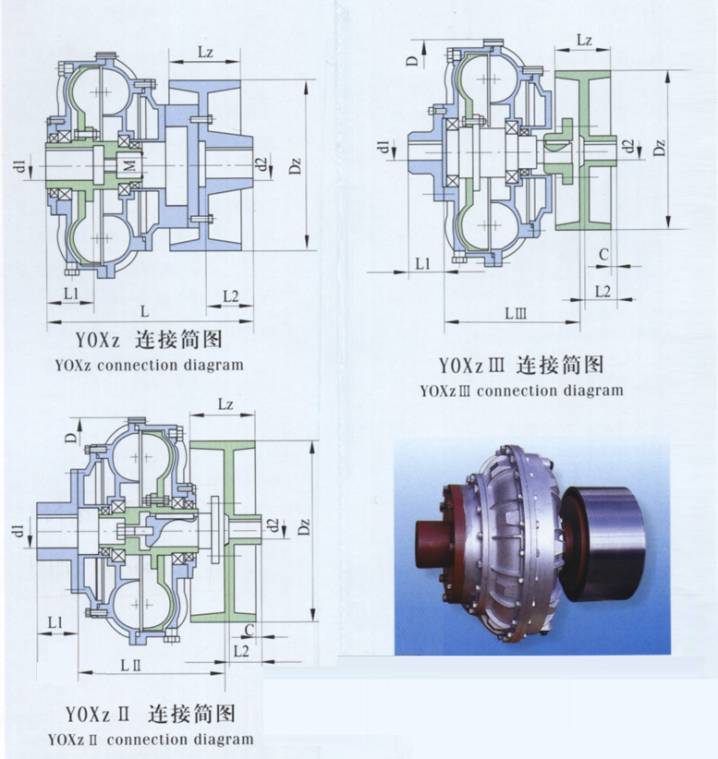

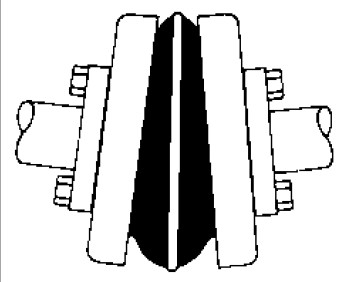

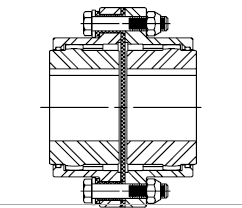

Fluid couplings

Attention:

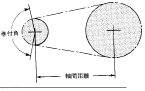

the smallest dimension Dp belt tray can do. the biggest size the dl axle hole can do YOXp style is actually a connection kind of belt tray with hydraulic coincidence machine. The electromotive machine (or decelerating machine) axle straight inserts from the axle hole from the coincidence machine which can be appropriate in tools transported by belt.

Client will have to provide the connection dimension of electromotive machine axle (d1 L1) as well as thorough specification and size of belt tray.

YOXm is 1 the axle of decelerating machine right inserts from the axle hole of coincidence machine as well as electromotive machine stage ML(GB5272-85) connects with plum blossom kind elastic axle connecting machine.

It is actually trusted linked and has uncomplicated structure, the smallest axle size which is a widespread connection variety in existing tiny coincidence machine.

Client should supply the dimension of electromotive machine axle (d1 L1) and decerating machine axle (d2 L2) as proven inside the picture, some others if client tend not to supply, we are going to manufacture according to the sizes during the table.

Attention:L while in the table may be the smallest axle dimension. If lengthen the L1,the complete length of L will likely be extra.d1,d2are the biggest dimension that we are able to do.

YOXf is actually a sort linked both sides, the axle size of and that is longer. But it has uncomplicated structure and it truly is additional practical and less complicated for fixing and amending (needless to move the electromotive machine and decelerating machine but only the elastic pillar and connecting spiral bolt can unload the coincidence machine).

The pertinent elastic axle connecting machine, connecting size and outer dimension is basically the same with YOXe type.

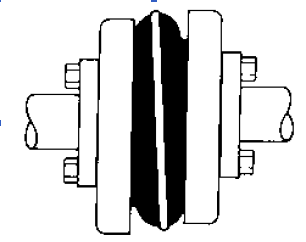

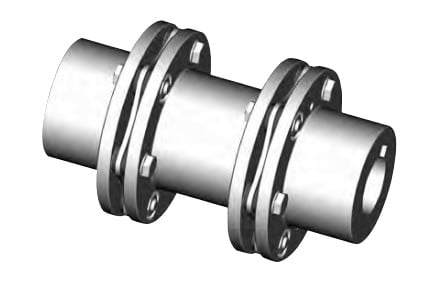

Flexible Coupling Model is extensively applied for  its compact designing,easy installation,convenient maintenance,small size and light weight.As long as there lative displacement in between shafts is stored inside the specified tolerance,the coupling will

its compact designing,easy installation,convenient maintenance,small size and light weight.As long as there lative displacement in between shafts is stored inside the specified tolerance,the coupling will

operate the most beneficial function in addition to a longer doing work life,thus it really is drastically demanded in medium and minor electrical power transmission

programs drive by motors,such as velocity reducers,hoists,compressor,spining &weaving machines and ball mills,permittable

relative displacement: Radial displacement 0.2-0.6mm; Angel displacement 0o30′–1o30′

Fluid couplings

Functions:

Strengthen the starting capability of electric motor, shield motor against overloading, damp shock, load

fluctuation and torsional vibration, and stability and load distribution in situation of multi motor drives.

Applications:

Belt conveyers, csraper conveyers, and conveyers of all sorts Bucket elevators, ball mills, hoisters, crushers,

excavators, mixers, straighteners, cranes, and so on.

Assortment:

Without particular demands the following technical data sheet and electrical power chart are made use of to pick the proper dimension of

fluid coupling with oil medium in accordance to your power transmitted plus the velocity of motor, e, i, the input of the fluid coupling.

When ordering, please specify the dimensions of your shaft ends of motor and driven machine(or reducer)together with

diameter, tolerance or match from the shafts (if no tolerance or match is specified, the bores will likely be machined the H7),fit length of the

shafts, width and depth of your keys (of notice the standard No. enforced).For ordering the fluid couplings with belt pulley, brake

pulley or even the special specifications please state the technical data in detail.

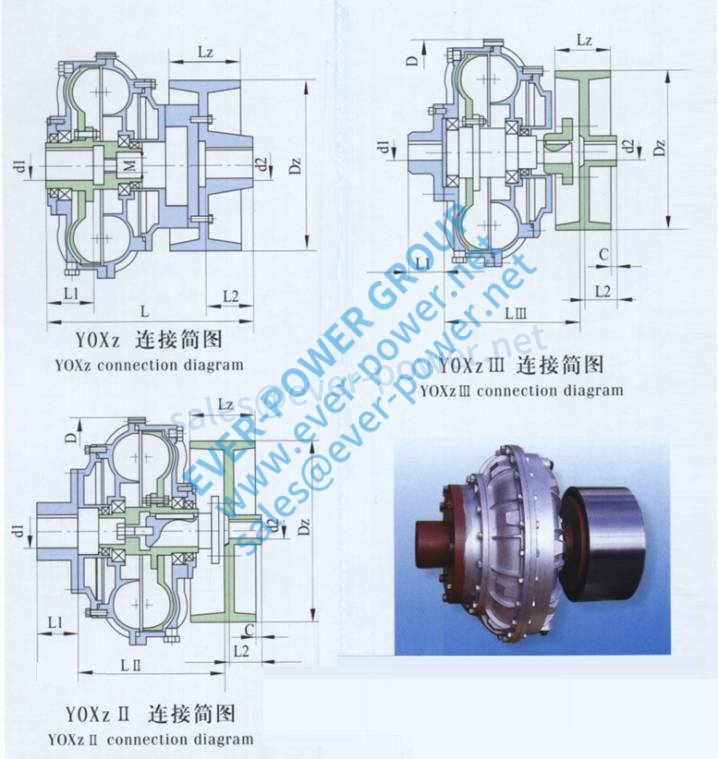

YOXz is usually a coincidence machine with moving wheel that’s from the output point in the coincidence machine

and it is connected with elastic axle connecting machine (plum blossom variety elastic axle connecting machine or

elastic pillar axle-connecting machine or  even the axle-connecting machine designated by buyers). Usually

even the axle-connecting machine designated by buyers). Usually

you will find 3 connection styles.

YOXz is inner wheel driver which has tight framework and also the smallest axle size. The fittings of YOXz possess a wide

usage, basic construction plus the size of it has fundamentally be unified while in the trade. The connection kind of YOXz is that

the axle dimension of it really is longer nevertheless it is unnecessary to move the electromotive machine and decelerating machine. Only

demolish the weak pillar and connected spiral bolt can unload the coincidence machine so it can be excessive easy.

Consumer should provide the size of electromotive machine axle (d1 L1) and decelerating machine axle (d2 L2). The

wheel size (Dz Lz C) in the table is only for reference, the actual dimension is decided by prospects.

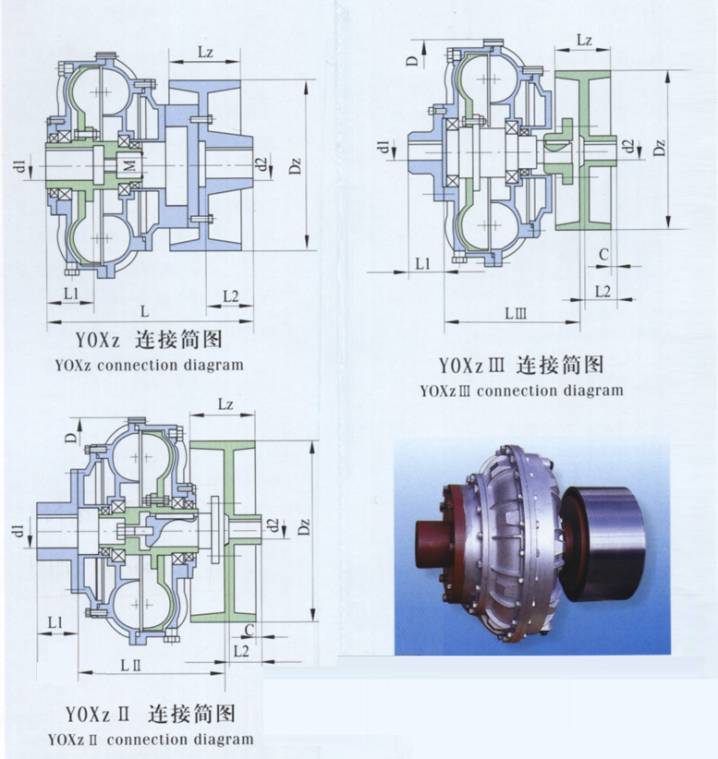

Fluid couplings

Attributes:

Strengthen the commencing capability of electric motor, protect motor towards overloading, damp shock, load

fluctuation and torsional vibration, and balance and load distribution in case of multi motor drives.

Applications:

Belt conveyers, csraper conveyers, and conveyers of all sorts Bucket elevators, ball mills, hoisters, crushers,

excavators, mixers, straighteners, cranes, and so on.

Choice:

With out special requirements the next technical information sheet and power chart are utilised to pick the right dimension of

fluid coupling with oil medium according  for the energy transmitted and also the speed of motor, e, i, the input on the fluid coupling.

for the energy transmitted and also the speed of motor, e, i, the input on the fluid coupling.

When ordering, please specify the dimensions in the shaft ends of motor and driven machine(or reducer)together with

diameter, tolerance or match with the shafts (if no tolerance or match is specified, the bores might be machined the H7),fit length in the

shafts, width and depth in the keys (of observe the conventional No. enforced).For ordering the fluid couplings with belt pulley, brake

pulley or the particular requirements please state the technical information in detail.

YOXz is usually a coincidence machine with moving wheel that’s from the output point from the coincidence machine

and is linked with elastic axle connecting machine (plum blossom variety elastic axle connecting machine or

elastic pillar axle-connecting machine and even the axle-connecting machine designated by buyers). Normally

you’ll find 3 connection varieties.

YOXz is inner wheel driver which has tight framework as well as the smallest axle size. The fittings of YOXz have a broad

utilization, straightforward framework as well as the size of it’s in essence be unified inside the trade. The connection kind of YOXz is

the axle dimension of it can be longer nonetheless it is pointless to move the electromotive machine and decelerating machine. Only

demolish the weak pillar and linked spiral bolt can unload the coincidence machine so it really is extreme practical.

Customer should offer you the size of electromotive machine axle (d1 L1) and decelerating machine axle (d2 L2). The

wheel dimension (Dz Lz C) within the table is just for reference, the real dimension is made the decision by consumers.

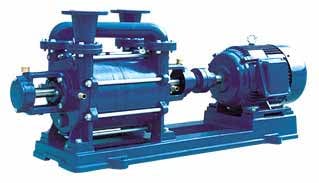

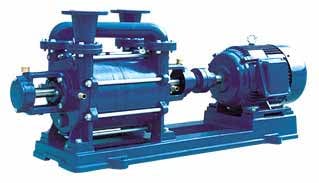

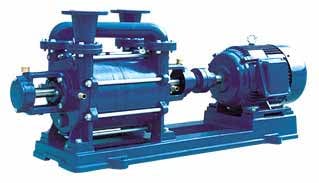

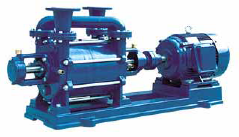

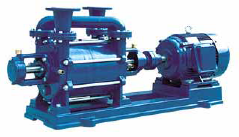

ROOTS VACUUM PUMPS

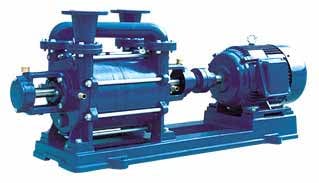

Working Principle and Capabilities: The series SYF roots vacuum pump is with overflow valve. The figure-of-eight rotors are counter-rotating at a constant speed within the pump housing for suction and exhaust of gasoline. Two rotors are supported by two bearings and synchronized by a gear, which assures these two rotors in particular relative positions. They are really near to each other and to the housing without having real contacting, so lubrication is unnecessary from the operating housing. The cautiously balanced operating parts and higher precision bevel wheels ensue the pump be operated stably and continuously underneath the condition of high-pressure big difference. Dynamic seal component employs our patent technology and imported oil seals, the vibration quantity of shaft within the shaft seals is controlled to significantly less than 0.02mm. A gravity valve is installed involving the suction and exhaust a part of the pump. The function from the gravity valve is as follows, once the stress distinction amongst the suction and exhaust portion is more than the excess weight of the valve, the valve opens instantly, which tends to make the strain difference often continue to keep inside a fixed controllable value, the value would be the allowable highest stress distinction to make sure the pump operate generally and to ensure in reality, the roots vacuum pump with overflow valve is usually a form of overload self-protective pump. Series SYF roots vacuum pump with overflow valve has considerably higher speed at comparatively decrease inlet strain and it is possessed overload self-protective function. Because it is often a pump of dry clearance seal construction, if a particular pumping velocity rate 15 and an ultimate vacuum should be obtained, it really is needed to provide a reduced inlet strain for lowering the back flow, as a result,  a pump must be backed in use, roots vacuum pump ought to be began quickly soon after its inlet strain reaches a permissible worth for economization. It is actually permit to select distinctive sorts of pump because the backing pump for factual prerequisites, such as oil seal pump and liquid ring vacuum pump. When pumping the gasoline containing significant amount of vapor, the liquid ring vacuum pump may be the great backing pump.

a pump must be backed in use, roots vacuum pump ought to be began quickly soon after its inlet strain reaches a permissible worth for economization. It is actually permit to select distinctive sorts of pump because the backing pump for factual prerequisites, such as oil seal pump and liquid ring vacuum pump. When pumping the gasoline containing significant amount of vapor, the liquid ring vacuum pump may be the great backing pump.

SINGLE STAGE VACUUM PUMPS

110/220VAC Vacuum Pumps

Single stage vacuum pumps operate on 110 VAC or 220VAC. Picking the correct size pump from 1.five cfm to 9 cfm is determined by your unique application. These pumps 1 engineered exclusively to aid you do your career faster and better.

Higher efficiency-CFM rated as ?¡ãfree air displacement.?¡À150micron discipline rating. Hefty duty high torque motor-assures cold weather staring.

Low working temperature-improve efficiency and vacuum.

Forced-feed lubrication design-help cut down operating temperature and superior Lubrication.

DUAL STAGE VACUUM PUMPS

110/220VAC Vacuum Pumps

Dual stage vacuum pumps operators on 110 VAC or 220VAC.Advanced dual-stage style and design pulls deep vacuum to 50 microns. Layout of these one.five,three,five,8,10,12 CFM pump enhancements develop around the performance-proven top quality characteristics. What ever your vacuum pump wants, the ideal pump will go to work with you.

Dual stage design-second stage commences pumping at a reduce stress to pull a deeper greatest vacuum.

Stopping oil-returning design-prevents pump oil from currently being sucked to the procedure if a energy reduction happens.

Gas ballast-speeds evacuation and keeps oil cleaner. Massive oil reservoir-lightweight and better dilute corrosive contaminants.

ROTARY PISTON VACUUM PUMPS

The series HGL, HG pump is a sort of single-stage and single-cylinder rotary piston vacuum pump. It’s drastically improved series H rotary piston pump and consists  of 4 patents; its common abilities have a good improvement. Rotary piston vacuum pump is often a sort of vacuum manufacturing equipment ideal for pumping ordinary gases and condensable gases(whenever a gas ballast employed). The pump need to be fitted with appropriate equipment if gas is wealthy in oxygen, explosive, corrosive to ferrous metal, chemical reactive with vacuum pump oil. Operation principle display in doing work principle graph: A rotary piston with slide valve across eccentric wheel driven by shaft within the housing. Piston pole can slide and swing freely in arch track. The entire pump chamber is divided into chamber A and chamber B by piston. When shaft rotates the volume of chamber A and chamber B are changed repetitively, so that pumping objective could be attained.

of 4 patents; its common abilities have a good improvement. Rotary piston vacuum pump is often a sort of vacuum manufacturing equipment ideal for pumping ordinary gases and condensable gases(whenever a gas ballast employed). The pump need to be fitted with appropriate equipment if gas is wealthy in oxygen, explosive, corrosive to ferrous metal, chemical reactive with vacuum pump oil. Operation principle display in doing work principle graph: A rotary piston with slide valve across eccentric wheel driven by shaft within the housing. Piston pole can slide and swing freely in arch track. The entire pump chamber is divided into chamber A and chamber B by piston. When shaft rotates the volume of chamber A and chamber B are changed repetitively, so that pumping objective could be attained.

VACUUM PUMPS OF SPIRAL SLICE Style Use scope The single stage oil cycle vacuum pumps of spiral slice variety of  series SYF and double stage oil cycle vacuum pumps of spiral slice sort on the series of 2SYF are important tools for abstracting the gasoline from obturational container to acquire vacuum. The double stage vacuum pumps of spiral slice form of your series of 2SYF applied for abstracting to get vacuum once again around the basis of single stage pumps. It can make the procedure realize the highest point vacuum. Options (one) The design of preventing oil-returning The passage of fuel admission is specially built to avert the returning of pumps oil delivering the abstracted container and pipeline right after the pumps prevent operating. (two) The style and design of environmental protection The style and design of built-in gadget of mist getting rid of, and set oil-gas seperator on the vent, the two manage the pollution of oil through the course of exhausting efficiently. (3) Aluminum alloy casing of electrical machinery The electric machinery use aluminum alloy casing, it has higher efficiency of heat emission, and guarantee very long time ordinary operation continously, additionally, it has far better physical appearance excellent. (four) The style of integration The electrical machinery and pumps utilize the style of integration generating the items much more significant and reasonable. (5) Big starting up minute Our product or service models specially aiming in the setting of lower temperature and electric pressure. ensuring the machine commences typically at decrease temperature of winter setting(?Y-5??) and reduced electrical pressure(?Y180V).

series SYF and double stage oil cycle vacuum pumps of spiral slice sort on the series of 2SYF are important tools for abstracting the gasoline from obturational container to acquire vacuum. The double stage vacuum pumps of spiral slice form of your series of 2SYF applied for abstracting to get vacuum once again around the basis of single stage pumps. It can make the procedure realize the highest point vacuum. Options (one) The design of preventing oil-returning The passage of fuel admission is specially built to avert the returning of pumps oil delivering the abstracted container and pipeline right after the pumps prevent operating. (two) The style and design of environmental protection The style and design of built-in gadget of mist getting rid of, and set oil-gas seperator on the vent, the two manage the pollution of oil through the course of exhausting efficiently. (3) Aluminum alloy casing of electrical machinery The electric machinery use aluminum alloy casing, it has higher efficiency of heat emission, and guarantee very long time ordinary operation continously, additionally, it has far better physical appearance excellent. (four) The style of integration The electrical machinery and pumps utilize the style of integration generating the items much more significant and reasonable. (5) Big starting up minute Our product or service models specially aiming in the setting of lower temperature and electric pressure. ensuring the machine commences typically at decrease temperature of winter setting(?Y-5??) and reduced electrical pressure(?Y180V).

Ever-Power Vacuum Pumps Co.,Ltd.

Manufacturer of: Vacuum pumps of spiral slice type, Rotary Piston vacuum pumps, Roots Vacuum pumps, Cas-Cooling Roots Vacuum pumps, Rotary Vane Vacuum Pumps, Water ring Vacuum Pumps, Reciprocating vacuum pumps and Vacuum valves and verify values together with other linked vacuum goods and program. Hangzhou Ever-Power Vacuum Pumps Co.,Ltd. We now have the strongest improvement potential of vacuum pumps and vacuum equipment technologic. Corporation has advanced design and style, Advanced gear, the largest vacuum pumps check center in China, also has already established the stringent Q/C systemas per ISO9001 regular. You can find complete 25 key series of vacuum products, Our products are extensively utilized in departments of metallurgical,  constructing elements, petroleum, environmental, proteion, chemical, medicine, textiles, food, aerospae, electronic, electrical power, nationwide defence industries and science analysis and so on.

constructing elements, petroleum, environmental, proteion, chemical, medicine, textiles, food, aerospae, electronic, electrical power, nationwide defence industries and science analysis and so on.

LIQUID (WATER) RING VACUUM PUMPS

Working principle and options: For that series SK, 2SK, YK and 2YK liquid ring vacuum pumps, multi-vane impeller is fixed eccentrically inside the pump casing. When the vanes rotate, the liquid within the casing types a liquid ring which is concentric with the pump casing under the centrifugal impact, the cubage involving liquid and vanes have a periodic change, so the function of pumping be performed. Liquid ring vacuum pumps are in the attributes of lower energy consumption and very low noise. They will be employed to pump water vapor, inflammable and explosive gas too as ordinary gases. With particular supplies employed for big components, they’re able to also pump corrosive gas. Suitable actuating medium or often pumped medium is often chosen as actuating liquids, so the pumps can practically take care of all extensively used for light, chemical, meals, electrical energy and pharmaceutical industries, etc.

Observing a handful of guidelines for appropriate installation is important on the reliable and appropriate operation on the gearbox or gear motor.

The principles set out listed below are meant as being a preliminary manual to selecting gearbox or gear motor. For successful and right set up, stick to the instructions given within the installation, use the maintenances manual for that gearbox available from our product sales division.

Following is usually a brief outline of installation rules:

a) Fastening:

Place gearbox on the surface giving satisfactory rigidity. Mating surfaces needs to be machined and flat.

Mating surfaces must be within definite geometric tolerances (see guide). This is particularly correct of flange-mounted gearboxes with splined hollow shafts.

In applications that involve large radial loads at the output end, flange mounting is recommended for some gearbox sizes as this mounting can make use of the double pilot diameters offered in these gearboxes.

Ensure that the gearbox is suitable for that needed mounting place.

Use screws of resistance class 8.eight and over to secure the gearbox. Torque up screws to the figures

indicated while in the related tables.

With transmitted output torque better than or equal 70% from the indicated M2max torque, and with

regular motion reversals, use screws with minimal resistance ten.9.

Some gearbox sizes can be fastened making use of both screws or pins. Of pin seated while in the frame the gearboxes be no less than 1.5 occasions pin diameter.

b) Connections

Safe the connection parts to gearbox input and output. Will not  tap them with hammers or very similar equipment.

tap them with hammers or very similar equipment.

To insert these elements, make use of the services screws and threaded holes offered about the shafts. Be sure you clean off any grease or protects from the shafts prior to fitting any connection components.

Fitting hydraulic motors.

Be cautious the O ring in between motor flange and gearbox input flange when assembling. Install the

hydraulic motor just before filling lube oil in to the gearbox.

Connecting the hydraulic brake.

The hydraulic circuit must be such to guarantee that brake is released instants before gearbox commences and applied right after gearbox has stopped. Test that stress inside the hydraulic line for brake release is at zero each time gearbox is stopped.

Route of rotation

Motors are connected on the suitable electric or hydraulic circuit in line with their course of rotation.

When performing these connections, keep in mind that all gearboxes, irrespective of whether while in the in-line or right angle style, possess the exact same route of rotation each at input and output. For additional specifics of your connection of electrical and hydraulic motors, see appropriate sections on this catalogue.

TF Variety Flanges

Model TF flanges are made from the same high-strength cast iron as the S flanges, but are built to accommodate the international standard Taper Lock bushing for straightforward installation and elimination

TF Sort flanges make it possible for for mounting the bushing on the front (hub) side of your flange

TF flanges can be found in sizes 6 by means of sixteen and may be employed with any kind of sleeve as pictured on webpage SF-5

TR Kind Flanges

TR flanges are equivalent towards the TF style, but enable for that Taper Lock Bushing to get mounted and eliminated from

the reverse or serration side of the flange

The restricted torque ratings from the Taper Lock Bushings permit TR flanges to only be applied with EPDM or Neoprene  sleeves

sleeves

Various bushing sizes are utilised, so they’ve unique highest bores than the TF flanges

Sizes six through sixteen can be found

Taper-Lock Bushings

The industry normal taper lock bushing can be a split design making it possible for a compression match in the flange towards the shaft without the need of set screws

The very simple design and style can make the installation and removal easy even though the 8° taper grips tight and delivers great concentricity

A Diminished degree of inventory could be accomplished because of the many other energy transmission parts that use Taper Lock Bushings for instance: sheaves, sprockets, and pulleys

won’t present the Taper-Lock Bushings themselves as these are extensively accessible from other manufacturers

B Form Flange

Model B (bushed) flanges are produced in the very same high-strength cast iron because the S flanges

B flanges are created to accommodate the marketplace common bushing for simple set up and removal

B flanges are available in sizes six by sixteen

Couplings

S-Flex couplings with B flanges (for use with bushings) are generally provided using the two-piece E sleeve

The B type flanges may be applied with any from the sleeves pictured on SF-5, with all the exception in the Hytrel sleeve

B flanges is often used in blend with S Variety flanges

Bushings

Bushings  possess a split style and design that make it possible for for a compression fit for safe mounting with the flange to your shaft without the need of set screws

possess a split style and design that make it possible for for a compression fit for safe mounting with the flange to your shaft without the need of set screws

The bushing’s clamp like fit produces a one-piece assembly to reduce wobble, vibration, and fretting corrosion

Somewhat oversized or undersized shafts might be accommodated with all the same secure grip

The design prevents possibly hazardous essential drift on applications topic to pulsation or vibration

B flanges are bored to accept a bushing accommodating a lot of bore sizes, as a result decreasing inventory and rising coupling versatility

Bushing bore availability is usually identified in existing listing price tag books or out of your Customer service Representative

S-Flex Sleeves

Versatile sleeves for S-Flex couplings can be found in three components (EPDM, Neoprene, and Hytrel) and in three simple designs: 1 piece reliable, one-piece split, or two piece

JE, JN, JES and JNS Sorts

JE and JN Sort sleeves function a one-piece sound layout

JES and JNS Type sleeves characteristic a one-piece split design

JE and JES Type sleeves are molded in EPDM material

JN and JNS Kind sleeves are molded in Neoprene material

E and N Sorts

E and N Type sleeves feature a two-piece style with retaining ring

E Sort sleeves are made from EPDM materials and are offered in sizes 5-16

N Style sleeves are made from Neoprene material and therefore are offered in sizes 5-14

Two piece sleeves are great for applications the place smaller shaft separations inhibit the set up of the 1 piece sleeve

H and HS Sorts

H and HS Type sleeves are created for higher torque applications, transmitting about four instances as substantially energy as an equivalent EPDM or Neoprene sleeve

Hytrel sleeves are available inside a one-piece strong (H) or two-piece split (HS) development

Hytrel sleeves might be applied only with S or SC  flanges and can not be utilised with J or B flanges

flanges and can not be utilised with J or B flanges

Hytrel sleeves really should not be made use of as direct replacements for EPDM or Neoprene applications

H and HS Kind sleeves can be found for sizes 6-14 (sizes 13 and 14 can be found in HS only)

Approach

S-Flex Coupling Choice Course of action

The selection procedure for identifying the correct S-Flex coupling calls for using the charts shown about the following pages. You can find three elements for being picked, two flanges and a single sleeve.

Info required just before a coupling could be chosen: HP and RPM of Driver or working torque

HP and RPM of Driver or working torque

Shaft size of Driver and Driven gear and corresponding keyways

Application or products description

Environmental conditions (i.e. extreme temperature, corrosive situations, area limitations)

Methods In Choosing An S-Flex Coupling

Phase 1: Identify the Nominal Torque in in-lb of the application by using the following formula:

Nominal Torque = (HP x 63025)/RPM

Stage two: Utilizing the Application Services Issue Chart one choose the services factor which best corresponds for your application.

Phase three: Calculate the Style and design Torque of one’s application by multiplying the Nominal Torque calculated in Phase 1 through the Application Service Element determined in Phase 2.

Style and design Torque = Nominal Torque x Application Services Issue

Phase four: Using the Sleeve Overall performance Information Chart two decide on the sleeve materials which greatest corresponds to your application.

Phase five: Employing the S-Flex Nominal Rated Torque Chart three locate the suitable sleeve material column to the sleeve chosen in Stage 4.

Stage 6: Scan down this column for the 1st entry wherever the Torque Value inside the column is better than or equal for the Design and style Torque calculated in Stage three.

Refer for the maximum RPM worth on the coupling size to guarantee the application needs are met. If your greatest RPM worth is much less than the application requirement, S-Flex couplings are usually not recommended for your application.

Note:

If Nominal Torque is significantly less than 1/4 from the coupling’s nominalrated torque, misalignment capacities are diminished by 1/2. As soon as torque worth is found, refer on the corresponding coupling dimension inside the initially column with the S-Flex Nominal Rated Torque Data Chart three .

Step 7: Compare the application driver/driven shaft sizes towards the highest bore dimension available on the coupling selected. If coupling max bore will not be huge ample for the shaft diameter, decide on the subsequent biggest coupling that may accommodate the driver/driven shaft diameters.

Step eight: Applying the Item Assortment tables, come across the ideal Keyway and Bore dimension necessary and find the number.

We give versatile sleeve for S-Flex coupling in three styles: one-piece reliable, one-piece split, and two-piece with retaining ring

The one-piece split style gives answers for applications with one of a kind specifications in which little shaft separations inhibit the installation of the one-piece reliable sleeve

Pre-molded teeth along the diameter of your sleeve engage with teeth on the coupling flanges

No clamps or screws are needed to connect the flanges using the flexible sleeve which securely lock together underneath torque for smooth transmission of power

Torque is transmitted by way of shear loading in the sleeve

All 3 sleeve elements are highly elastic which permits the S-Flex coupling to guard connected products from hazardous shock loading, vibration, and shaft misalignment

JE, JN, JES, JNS Sleeve Types

These sleeves function a one-piece layout molded in EPDM & Neoprene rubber. In the case of JES & JNS Types, the one-piece style and design is split to provide for ease of set up and removal.

E, N Sleeve Varieties

These sleeves function a two-piece style and design with retaining ring. The E Type is molded in EPDM rubber and the N Type is molded in Neoprene. The two-piece style and design is ideal for applications in which there is difficulty in separating the shafts of your driver and driven.

H, HS Sleeve Types

These sleeves feature both a one-piece solid (H) and two-piece split

(HS) layout and are molded of Hytrel. The sleeves in Hytrel material are designed to transmit electrical power for high torque applications. Because with the layout and the properties of your Hytrel molded sleeve, the H and HS sleeves should not be used as direct replacements for EPDM or Neoprene sleeves, and can only be used with S, TF, or SC flanges.

Sleeve Supplies

EPDM ?§C Unless otherwise specified, S-Flex couplings are supplied with EPDM flexible sleeves. EPDM has good resistance to commonly used chemicals and is generally not affected by dirt or moisture. Color is  black.

black.

NEOPRENE ?§C Neoprene supplies very good performance characteristics for most applications and offers a very good resistance to chemical and oil conditions. Color is black with a green dot.

HYTREL ?§C Hytrel is a polyester elastomer designed for high torque and high temperature applications and offers excellent resistance to chemical and oil conditions. Color is orange.

Elastomer In Shear Style Couplings

The straightforward layout from the S-Flex coupling ensures ease of assembly and reliable overall performance. No specific equipment are required for installation or removal. S-Flex couplings is often utilized in a wide variety of applications.

Attributes

Uncomplicated to install

Maintenance Free of charge

No Lubrication

Dampens Vibration and Controls Shock

Torsionally Soft

Double Engagement

Characteristics and Effectiveness Facts

The S-Flex coupling design is comprised of three parts: two flanges with inner teeth engage an elastomeric versatile sleeve with external teeth

Torque is transmited by the flanges mounted on each the driver and driven shafts through the sleeve

Misalignment and torsional shock loads are absorbed by shear deflection while in the sleeve

The shear characteristic of your S-Flex coupling is very well suited to soak up influence loads

The S-Flex coupling presents combinations of flanges and sleeves which might be assembled to suit your unique application

Thirteen sizes can be found with torque capabilities that vary from 60 in-lbs to 72,480 in-lbs

The S-Flex flanges are made available in five models that are made from zinc or cast iron

Sleeves can be found in EPDM rubber, Neoprene to tackle a wide variety of application specifications

Safety from misalignment, shock, and vibration:

PARALLEL:

The S-Flex  coupling accepts up to .062 in of parallel misalignment without having wear. The flexible coupling sleeve minimizes the radial loads imposed on products bearings, a problem usually associated with parallel misalignment.

coupling accepts up to .062 in of parallel misalignment without having wear. The flexible coupling sleeve minimizes the radial loads imposed on products bearings, a problem usually associated with parallel misalignment.

AXIAL:

The S-Flex couplings is usually used in applications which call for a restricted amount of shaft end-float with out transferring thrust loads to gear bearings. Axial movement of around 1/8 inch accepted.

ANGULAR:

The flexing action of your elastomeric sleeve and also the locking function in the mating teeth makes it possible for the S-Flex coupling to correctly take care of angular misalignment up to 1??.

TORSIONAL:

S-Flex couplings efficiently dampen torsional shock and vibration to protect connected tools. The EPDM and Neoprene sleeves have torsional wind-up versatility of 15?? at their rated torque. Hytrel supplies 7??wind-up.

H Form Couplings

The H Sort coupling consists of two hubs, two inside sleeves, 1 cushion set and a single collar with hardware. H Form coupling hubs are supplied with an inside sleeve. For technical assistance, please get in touch with Lovejoy Engineering.

Attributes

Higher torque and bore capability compared to the C-Line series jaw coupling

Elastomeric cushions are radially removable

Cushions available in SXB rubber and Hytrel

RRC Variety Radially Removable Spacer Coupling

RRC Style couplings array from sizes RRC226to RRC2955.

The RRC Kind coupling consists of:

2 RRC Hub Adapters (includes bolts)

one Spacer assembly consisting of:

two RRC Jaw rings

one collar with hardware

1 set of SXB (NBR) cushions

L Kind Coupling

Sizes variety from L035 to L276

Ordering demands deciding on UPC numbers for two regular L hubs and one particular typical open or strong center elastomer (spider)

SW Form Coupling

Sizes assortment from L090 to L190

Ordering necessitates picking UPC numbers for two standard L hubs and one particular snap wrap spider with snap ring

The two L and SW Variety couplings, decide on hubs from your common bore and keyway chart (pages JW-11 and JW-12) greatest RPM for SW + Ring is 1,750 RPM

LC coupling makes use of a snap wrap spider that has a collar as an alternative of a retaining ring

Jaw In-Shear  Coupling

Coupling

Ordering involves selecting item numbers for two normal hubs, a single In-Shear elastomer and 1 In-Shear ring.

C Kind Couplings

The C Variety coupling consists of two typical hubs, 1 cushion set and collar with hardware.

Characteristics

Better torque and bore capability compared to the L-Line series jaw coupling

Elastomeric cushions are radially removable

Cushions accessible in SXB rubber and Hytrel

RRS and RRSC Variety Radially Removable Spacer Couplings

RRS Variety couplings selection from sizes RRS090 to RRS225. The RRS Style

coupling consists of:

RRS090 – RRS110:

2 Typical RRS Hubs

one Spacer Assembly consisting of:

2 snap wrap spiders w/o ring

two collars with screws

one spacer

RRS150 – RRS225:

1 Conventional RRS Hub

1 Normal RRSC Hub – Drilled for collar

1 Spacer Assembly consisting of:

2 snap wrap spiders w/o ring

2 collars with screws

1 spacer

Note:

RRS Kind Inch Hubs supplied typical with  two set screws at 90°.

two set screws at 90°.

Attributes

Regular API primarily based spacers obtainable

Radially removable inserts

Normal Lovejoy hub style with more set screw at 90°

The LC Variety coupling includes one particular common L Style hub (without collar attachment), one particular LC Form hub (supplies collar attachment), one typical snap wrap center and one collar with screws. Functions

Radially removable insert

Collar lets for optimum velocity of 3,600 RPM

Collar manufactured from 1018 Steel

Notes:

These “LC” hubs are drilled and tapped to accept collar mounting screws however the collar and hardware are certainly not incorporated.

See L Variety (inch or metric) coupling chart for conventional hub.

Tolerances for bore and keyways are uncovered in Engineering Data part .

All hubs are supplied normal with 1 set screw.

When referencing the quantity within this table, involve 685144 as a prefix towards the quantity proven.

AL and SS Variety Couplings

The AL Type coupling consists of two hubs and one particular spider.

Features

Interchangeable with all hub sizes common for your L-Line and AL-Line goods

Readily available in a variety of distinctive finished bore and keyway combinations

Completed bores passivated for added rust safety

AL Sort Couplings

The AL Variety coupling includes two hubs and one particular spider.

Options

Aluminum material is corrosion resistant

Light-weight

Hubs compatible with normal Lovejoy hub layout (except AL150)

Jaw Sort Coupling Selection Approach

The selection procedure for figuring out the proper jaw coupling dimension and elastomer demands making use of the charts proven about the following pages. You can find three parts for being selected, two hubs and a single elastomer. When the shaft size of the driver and driven in the application are in the very same diameter, the hubs selected will be exactly the same. When shaft diameters differ, hubs chosen will vary accordingly.

Info needed before a coupling could be selected:

HP (or KW) and RPM or Torque of driver

Shaft sizes of driver and driven equipment and corresponding keyways

Application description

Environmental ailments (i.e. excessive temperature, corrosive disorders, room limitations)

Ways In Deciding on A Jaw Coupling

Stage one: Figure  out the Nominal Torque of one’s application by utilizing the next formula:

out the Nominal Torque of one’s application by utilizing the next formula:

Nominal Torque = in-lb = (HP x 63025)/RPM

Nm = (KW x 9550)/RPM

Phase two: Working with the Application Service Variables Chart 1 select the support issue which best corresponds for your application.

Phase 3: Calculate the Layout Torque of the application by multiplying the Nominal Torque calculated in Phase 1 through the Application Services Aspect established in Stage two.

Design and style Torque = Nominal Torque x Application Services Factor

Phase four: Working with the Spider Performance Data Chart 2, pick the elastomer materials which greatest corresponds to your application.

Step 5: Working with the Jaw Nominal Rated Torque Chart 3 , locate the appropriate elastomer material column for that elastomer picked in Step 4.

Scan down this column to your initial entry in which the Torque Worth inside the ideal column is greater than or equal to the Design Torque calculated in Step three.

The moment this worth is found, refer on the corresponding coupling dimension in the first column from the Jaw Nominal Rated Torque Chart 3 .

Refer for the greatest RPM worth for this elastomer torque capability to make sure that the application requirements are met. In the event the requirement is not happy at this point, a further kind of coupling can be expected for the application. Please seek advice from Lovejoy engineering for help.

Step six: Compare the application driver/driven shaft sizes on the greatest bore size out there around the coupling selected. If coupling bore size is not massive enough for your shaft diameter, pick the following greatest coupling that will accommodate the driver/driven shaft diameters.

Step 7: Making use of the UPC amount selection table , find the proper Bore and Keyway sizes essential and locate the quantity.

Elastomers In Compression

We gives four styles of elastomer styles to allow for more versatility in addressing certain application demands. 1 piece designs are utilized in the “L” and “AL” models (referred to as spiders) and a number of component “load cushions” are utilized in the “C” and “H” model couplings. The load cushions are in sets of 6 to 14 pieces according to coupling dimension.

Strong Center Spider

The sound center design and style is normally applied design when shafts on the driver and driven equipment is usually stored separate by a standard gap

Open Center Spider

The open center design and style lets for the shafts of your driver and driven to be positioned inside a brief distance

Open center spiders give shaft positioning flexibility but possess a lower RPM capacity

Cushions

Utilized exclusively to the C and H Style couplings

Load cushions are held in area radially by a steel collar and that is connected to one of many hubs

Snap Wrap Versatile Spider

Layout enables for straightforward removal with the spider without the need of moving the hubs

Will allow for shut shaft separation all of the way as much as the hubs optimum bore

Maximum RPM is one,750 RPM together with the retaining ring, but if applied together with the LC Type (with collar) the ordinary RPM rating on the coupling applies

Type is accessible in NBR and Urethane only, and in restricted sizes

Spider Products

SOX (NBR) Rubber

The standard material that may be extremely versatile material that is certainly oil resistant

Resembles natural rubber in resilience and elasticity, and operates proficiently in  temperature ranges of -40° to 212° F (-40° to 100° C)

temperature ranges of -40° to 212° F (-40° to 100° C)

Urethane

Has one.five times better torque capacity than NBR

Superior resistance to oil and chemicals

Material offers much less dampening result and operates at a temperature range of -30° to 160° F

Hytrel

Flexible elastomer developed for higher torque and substantial temperature operations

Operates in temperatures of -60° to 250° F (-51° to 121° C)

Bronze

Rigid, porous, oil-impregnated metal insert solely for reduced speed (max 250 RPM) applications requiring substantial torque capabilities

Not affected by water, oil, grime, or intense temperatures – operates in temperatures of -40° to 450° F (-40° to 232° C)

The Jaw Style couplings are made available during the industry?¡¥s biggest selection of stock bore/keyway combinations. These couplings demand no lubrication and offer hugely trustworthy support  for light, medium, and hefty duty electrical motor and inner combustion electrical power transmission applications.

for light, medium, and hefty duty electrical motor and inner combustion electrical power transmission applications.

Attributes

Fail-safe ¡§C will nevertheless carry out if elastomer fails

No metal to metal contact

Resistant to oil, filth, sand, moisture and grease

Additional than 850,000 combinations of bore sizes

Most kinds readily available from stock in 24 hrs

Applications include power transmission to industrial tools which include pumps, gear boxes, compressors, blowers, mixers, and conveyors. Jaw Sort couplings are available in 24 sizes from a minimal torque rating of 3.5 in¡§Clbs to a greatest torque rating of 170,004 in¡§Clbs along with a bore choice of .125 inches to 7 inches.Our typical bore program covers AGMA, SAE, and DIN bore/keyway and spline bore combinations.

The Jaw Form coupling is obtainable in the variety of metal hub and insert products. Hubs are provided in sintered metal, aluminum, bronze, steel, stainless steel, and ductile iron.

L Style

Coupling provides regular shaft-to-shaft connection for general industrial duty applications

Normal L Form coupling hub materials are either sintered iron or cast iron

LC Kind

Utilizes the conventional L Form hubs using a snap wrap spider and retaining ring

Suited for applications more than 1,750 RPM

AL Type

Aluminum hubs offer you light bodyweight with minimal overhung load and low inertia

Fantastic resistance to atmospheric disorders, fantastic for corrosive environment applications

SS Form

The SS Style coupling provides optimum safety towards harsh environmental conditions

Sizes SS075-SS150 out there from stock, other sizes available on request

RRS Style

Center ?¡ãdrop out?¡À segment of this coupling presents appropriate shaft separation, although also allowing quick elastomer installation without disturbing the hubs or requiring the realignment of shafts

Accommodates American and European field regular pump/motor shaft separations

The spacer is produced of glass reinforced plastic, cast iron, or aluminum

SW Type

Standard L Form coupling that has a snap wrap elastomer with retaining ring

Nicely suited for normal shaft to shaft connection on the whole industrial objective applications beneath 1,750 RPM

C & H Forms

Couplings provide regular shaft-to-shaft connection for medium (C) and Heavy (H) duty range applications

Conventional C coupling hub is made of cast iron, whilst the H is constructed of ductile iron

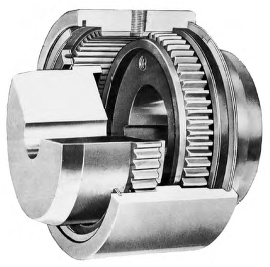

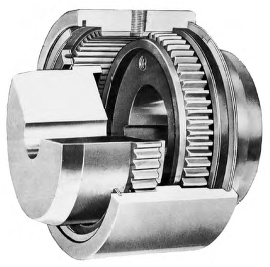

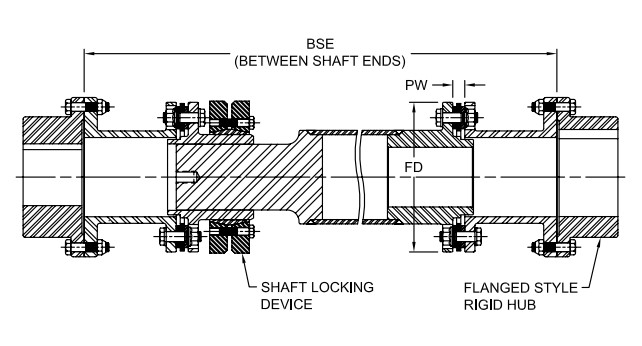

Common Grid Spacer and Half Spacer Style Couplings Horizontal Cover

The Grid Spacer coupling is an perfect coupling for applications in which there’s a necessity for some vibration dampening in installations that are not shut coupled. This implies some level of gap, or BSE exists involving the driver and driven equipment shafts.

All Grid Spacer Couplings are supplied with Horizontal Split Covers. The split cover style and design makes it possible for for speedy access to the grid spring for ease of servicing or grid spring substitute. The Horizontal Split Cover can also be great for applications wherever there may be some constraints to the diameter in the coupling.

Characteristics:

Made for ease of upkeep and grid spring substitute

High tensile grid springs make sure superior coupling overall performance and longer coupling daily life

Split covers permit for simple accessibility to grid springs

Interchangeable with sector common grid couplings

Normal Grid Type Couplings  Horizontal and Vertical Cover

Horizontal and Vertical Cover

The Grid coupling is an ideal coupling for applications the place outstanding efficiency is sought after and further demands for vibration dampening may well exist. The Horizontal Split Cover layout is advised in applications the place there may be some constraints

on the diameter on the coupling. The vertical style and design is recommended for applications the place increased pace is one of the needs.

Options:

Created for ease of upkeep and grid spring substitute

Substantial tensile grid springs guarantee superior coupling effectiveness and longer coupling existence

Split covers make it possible for for quick entry to grid springs

Interchangeable with industry normal grid couplings

The next details is necessary when producing a Grid coupling assortment:

Description of motor or engine, the horse energy (or KW), and RPM at slowest coupling pace while under load

Description of your driven tools

Shaft and keyway sizes as well as the sort of fit for driver and driven tools (clearance or interference)**

Shaft separation (BSE)

Physical space limitations (see Application Worksheet)

Figure out what  the environmental disorders will likely be, such as temperature, corrosive situations, interference from surrounding structures, and so on.

the environmental disorders will likely be, such as temperature, corrosive situations, interference from surrounding structures, and so on.

By default, sizes 1020 – 1090 is going to be clearance fit, sizes 1100 – 1200 are going to be interference fit.

** Machines all bores and keyways to meet the dimensional and tolerance specs per ANSI/AGMA 9002-B04 for inch bores, or ISO 286-2 for metric bores.

Standard grid couplings include two grid hubs, a grid spring, as well as a cover assembly. Once the shaft separation calls for a spacer fashion coupling, the coupling will include two shaft hubs, two spacer hubs, a grid spring, in addition to a horizontal cover assembly.

Formulas Utilised To Determine Torque:

Application Torque (in-lbs) = ( horse power x 63025 ) /RPM

Application Torque (Nm) = ( horse power x 9550 ) /RPM

Variety Torque = Application Torque x Support Aspect

Large Peak Loads and Brake Applications

For applications where higher peak loads or high braking torques may be existing, the next added details might be important:

System peak torque and frequency

Duty cycle

Brake torque rating

The variety torque formula is similar to the formula shown above except that the application torque needs to be doubled before applying the service factor.

Application Torque (in-lbs) = ( horse power x 63025 ) /RPM

Application Torque (Nm) = ( horse energy x 9550 ) /RPM

Choice Torque = two x Application Torque x Service Element

Ways In Choosing A Grid Coupling

Step 1: Establish the application torque working with the formula proven over.

Phase two: Choose the Services Factor in the charts .

For applications not displayed make use of the chart proven on the ideal. Ascertain the Selection Torque making use of the formula shown above.

Stage three: Using the variety torque as calculated, refer on the Effectiveness Chart

Step four: Review the utmost bore for your dimension selected and make sure the expected bore sizes usually do not exceed the utmost allowable. In case the essential bore size is greater, phase as much as the next size coupling and examine to check out in the event the bore sizes will fit.

Step 5: Employing the picked coupling size, compare the bore and keyway sizes

Step six: Speak to your nearby industrial supplier using the aspect numbers to location sizes using the charts for UPC element numbers.

The Power of Torsional Dampening

Our grid type coupling style has demonstrated its capacity to dampen vibration by around 30% and may cushion shock loads that could trigger damage to both the driving and driven gear. The tapered grid spring layout absorbs affect vitality by spreading the power out in excess of the complete length of the grid spring thus decreasing the magnitude of the torque spikes.

The Our design and style employs a curved hub tooth profile which generates a progressive get in touch with with the flexible grid spring because the application torque increases. This feature provides a a lot more efficient and productive transmission of power in adequately aligned couplings.

Our versatile layout of business normal hubs and grid springs

for each horizontal and vertical cover styles enable Our couplings

to be interchangeable with other sector conventional grid couplings and elements.

Good grid coupling installation and maintenance can add to a longer coupling life. Grid spring substitute is simple and  may be carried out at a fraction in the expense and time of a total coupling.

may be carried out at a fraction in the expense and time of a total coupling.

Functions

Large tensile, shot-peened alloy steel grid springs and precision machined hubs assure superior coupling performance and long existence.

Grid couplings with tapered grids are made to become interchangeable with other market typical grid couplings with the two horizontal and vertical grid covers.

Grid couplings are intended for ease of installation and maintenance decreasing labor and downtime expenses.

The torsional flexibility and resilience of grid couplings helps reduce vibration and cushions shock and influence loads.

Cover fasteners might be provided in either Inch or Metric sizes.

Outstanding for use in applications exactly where the gear is close coupled or spaced apart requiring a spacer design coupling arrangement.

Stock spacer designs can be found or requests for customized spacer lengths could be addressed by engineering.

Horizontal Split Cover Design

Excellent for restricted space

Permits effortless access towards the grid spring

Well suited for reversing applications

Lightweight die-cast aluminum grid cover

Vertical Split Cover Design and style

Great for increased working speeds

Will allow straightforward entry towards the grid spring

Cover is produced from stamped steel for strength

Full Spacer Design ¡§C Horizontal Cover

Drop-out design and style best for pump applications and servicing

Stock sizes 1020 thru 1090

Light-weight die-cast aluminum grid cover

Half Spacer Design and style ¡§C Horizontal Cover

Presents supplemental BSE dimensions

Light-weight die-cast aluminum grid cover

Why Coupling Grease?

Ample lubrication is essential for satisfactory gear coupling operation. Gear Coupling Grease is especially developed for gear coupling applications to increase coupling life although significantly cutting down maintenance time. Its substantial viscosity base oil and tackifier mix to maintain the grease in place and prevent separation and it really is in comprehensive compliance with NSI/AGMA 9001-B97 lubrication suggestions.

Coupling Grease is dark brown in shade and manufactured with a lithium soap/polymer thickener, which has superior resistance to oil separation when subjected to large centrifugal forces ordinarily discovered in couplings. Bearing or basic purpose greases usually separate and eliminate effectiveness as a result of large centrifugal forces about the a variety of elements at higher rotational speeds. These high centrifugal forces encountered in couplings separate the base oil in the thickeners. Hefty thickeners, which have no lubrication qualities, accumulate in the gear tooth mesh location leading to premature coupling failure. Gear Coupling Grease is made to very resistant to centrifugal separation of your oil and thickener, which enables the lubricant to be applied to get a comparatively prolonged period of time.

One of many strategies to your achievement of Gear Coupling Grease would be the variable consistency throughout the working cycle on the application. The consistency of our gear coupling grease changes with the working circumstances. Functioning from the lubricant below real services  problems leads to the grease to develop into semi-fluid, functionally solash lubricating the dress in surfaces from the coupling. Because the grease cools, it returns to the unique consistency, therefore preventing leakage.

problems leads to the grease to develop into semi-fluid, functionally solash lubricating the dress in surfaces from the coupling. Because the grease cools, it returns to the unique consistency, therefore preventing leakage.

Gear Coupling Grease is accessible from stock in 14 oz. cartridges, one lb. and 5 lb. cans.

Options

Minimizing of coupling wear

Resistance to water washing

Corrosion and rust protection

Higher load carrying abilities

Extended relubrication frequency

Use at temperatures as much as 325° F

Staying in spot under high speeds

Resistance to centrifugal separation

Reduction in down time & maintenance cost

Gear Coupling Grease has a consistency which overlaps the NLGI grades 0 and 1. This grease is specially formulated that has a lithium/polymer thickener and fortified with corrosion, oxidation, extreme pressure, and a effective rust inhibitor additive package.

Limited Finish Float Spacer Style

The addition of plates restricts axial travel for the drive or driven shaft. The spacer helps make it probable to remove the hubs from both shaft with no disturbing the connected units.

Vertical Floating Shaft Sort

The reduce coupling features a hardened crowned button inserted within the plate in the reduce hub. The complete floating assembly rest around the button. Optional construction on the upper coupling will be a rigid hub within the floating shaft having a flex half to the best.

Vertical Style

This coupling has the exact same horsepower, RPM and misalignment abilities because the typical couplings of corresponding sizes. A plate by using a hardened crowned button rests within the reduced shaft which supports the fat on the sleeve.

Insulated Sort

Use of a non-metallic material involving flanges and all-around the bolts prevents any stray currents from one shaft on the other.

Jordan Type

Applied on Jordan machines and refiners, this design is equivalent on the slide variety coupling except the lengthy hub  is split and secured towards the shaft that has a bolt clamp. This permits swift axial adjustment of the Jordan shafts i this hub.

is split and secured towards the shaft that has a bolt clamp. This permits swift axial adjustment of the Jordan shafts i this hub.

Engineered Shear Pin Form